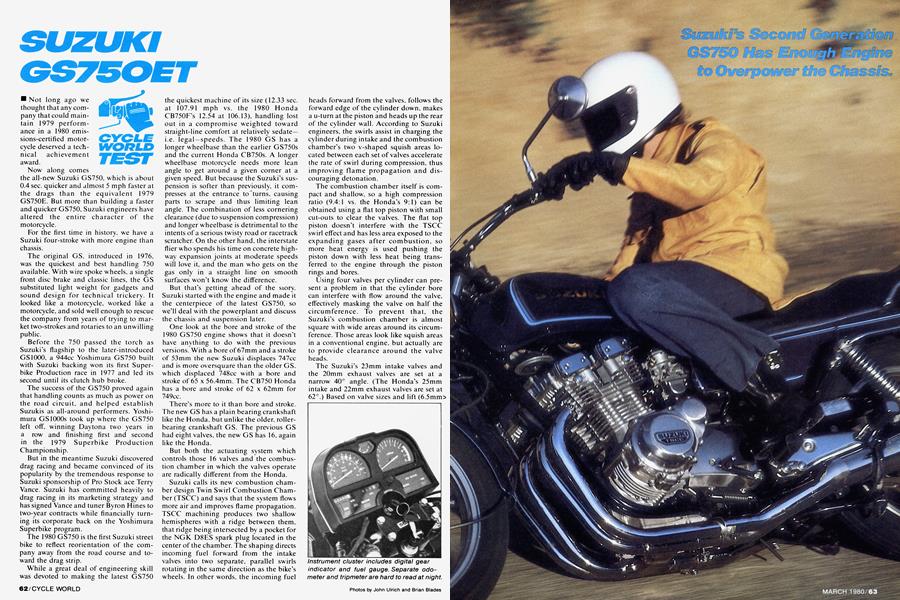

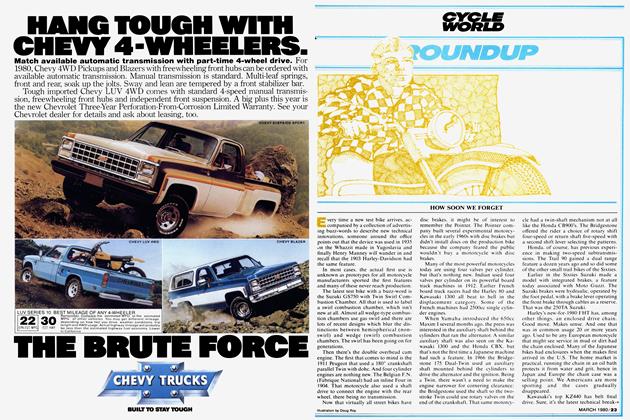

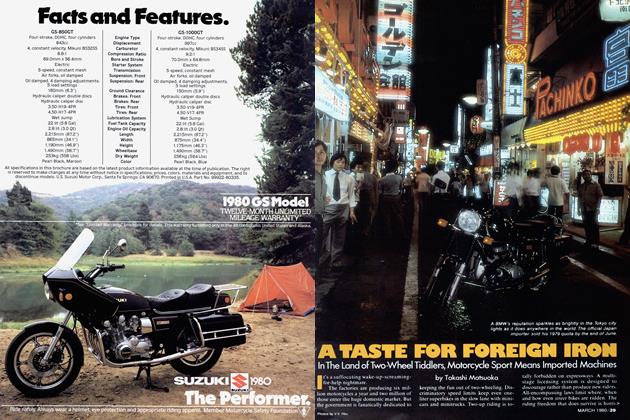

SUZUKI GS75OET

CYCLE WORLD TEST

Not long ago we thought that any company that could maintain 1979 performance in a 1980 emissions-certified motorcycle deserved a technical achievement award.

Now along comes the all-new Suzuki GS750, which is about 0.4 sec. quicker and almost 5 mph faster at the drags than the equivalent 1979 GS750E. But more than building a faster and quicker GS750, Suzuki engineers have altered the entire character of the motorcycle.

For the first time in history, we have a Suzuki four-stroke with more engine than chassis.

The original GS, introduced in 1976, was the quickest and best handling 750 available. With wire spoke wheels, a single front disc brake and classic lines, the GS substituted light weight for gadgets and sound design for technical trickery. It looked like a motorcycle, worked like a motorcycle, and sold well enough to rescue the company from years of trying to market two-strokes and rotaries to an unwilling public.

Before the 750 passed the torch as Suzuki’s flagship to the later-introduced GS1000, a 944cc Yoshimura GS750 built with Suzuki backing won its first Superbike Production race in 1977 and led its second until its clutch hub broke.

The success of the GS750 proved again that handling counts as much as power on the road circuit, and helped establish Suzukis as all-around performers. Yoshimura GS 1000s took up where the GS750 left off, winning Daytona two years in a row and finishing first and second in the 1979 Superbike Production Championship.

But in the meantime Suzuki discovered drag racing and became convinced of its popularity by the tremendous response to Suzuki sponsorship of Pro Stock ace Terry Vance. Suzuki has committed heavily to drag racing in its marketing strategy and has signed Vance and tuner Byron Hines to two-year contracts while financially turning its corporate back on the Yoshimura Superbike program.

The 1980 GS750 is the first Suzuki street bike to reflect reorientation of the company away from the road course and toward the drag strip.

While a great deal of engineering skill was devoted to making the latest GS750 the quickest machine of its size (12.33 sec. at 107.91 mph vs. the 1980 Honda CB750F’s 12.54 at 106.13), handling lost out in a compromise weighted toward straight-line comfort at relatively sedate— i.e. legal—speeds. The 1980 GS has a longer wheelbase than the earlier GS750s and the current Honda CB750s. A longer wheelbase motorcycle needs more lean angle to get around a given corner at a given speed. But because the Suzuki’s suspension is softer than previously, it compresses at the entrance to turns, causing parts to scrape and thus limiting lean angle. The combination of less cornering clearance (due to suspension compression) and longer wheelbase is detrimental to the intents of a serious twisty road or racetrack scratchen On the other hand, the interstate flier who spends his time on concrete highway expansion joints at moderate speeds will love it, and the man who gets on the gas only in a straight line on smooth surfaces won’t know the difference.

But that’s getting ahead of the siory. Suzuki started with the engine and made it the centerpiece of the latest GS750, so we’ll deal with the powerplant and discuss the chassis and suspension later.

One look at the bore and stroke of the 1980 GS750 engine shows that it doesn’t have anything to do with the previous versions. With a bore of 67mm and a stroke of 53mm the new Suzuki displaces 747cc and is more oversquare than the older GS. which displaced 748cc with a bore and stroke of 65 x 56.4mm. The CB750 Honda has a bore and stroke of 62 x 62mm for 749cc.

There’s more to it than bore and stroke. The new GS has a plain bearing crankshaft like the Honda, but unlike the older, rollerbearing crankshaft GS. The previous GS had eight valves, the new GS has 16, again like the Honda.

But both the actuating system which controls those 16 valves and the combustion chamber in which the valves operate are radically different from the Honda.

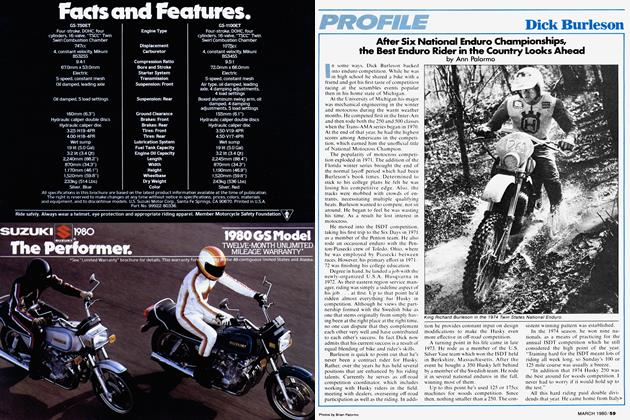

Suzuki calls its new combustion chamber design Twin Swirl Combustion Chamber (TSCC) and says that the system flows more air and improves flame propagation. TSCC machining produces two shallow hemispheres with a ridge between them, that ridge being intersected by a pocket for the NGK D8ES spark plug located in the center of the chamber. The shaping directs incoming fuel forward from the intake valves into two separate, parallel swirls rotating in the same direction as the bike’s wheels. In other words, the incoming fuel heads forward from the valves, follows the forward edge of the cylinder down, makes a u-turn at the piston and heads up the rear of the cylinder wall. According to Suzuki engineers, the swirls assist in charging the cylinder during intake and the combustion chamber's two v-shaped squish areas located between each set of valves accelerate the rate of swirl during compression, thus improving flame propagation and discouraging detonation.

The combustion chamber itself is compact and shallow, so a high compression ratio (9.4:1 vs. the Honda’s 9:1) can be obtained using a flat top piston with small cut-outs to clear the valves. The flat top piston doesn’t interfere with the TSCC swirl effect and has less area exposed to the expanding gases after combustion, so more heat energy is used pushing the piston down with less heat being transferred to the engine through the piston rings and bores.

Using four valves per cylinder can present a problem in that the cylinder bore can interfere with flow around the valve, effectively masking the valve on half the circumference. To prevent that, the Suzuki’s combustion chamber is almost square with wide areas around its circumference. Those areas look like squish areas in a conventional engine, but actually are to provide clearance around the valve heads.

The Suzuki’s 23mm intake valves and the 20mm exhaust valves are set at a narrow 40° angle. (The Honda’s 25mm intake and 22mm exhaust valves are set at 62°.) Based on valve sizes and lift (6.5mm>

Suzuki's Second Generation GS750 Has Enough Engine to Overpower the Chassis.

for both intake and exhaust in the case of the Suzuki, 7.8mm and 7.5mm for the Honda’s intake and exhaust, respectively), the Honda has more valve area than the Suzuki, 1225.22mm2 vs. 939.34mm2 intake and 1036.72mm2 vs. 816.81mm2 exhaust, when valve area is calculated as being the area of cylindrical shape between the circumference of the valve and the circumference of the valve seat at maximum lift value.

But camshaft timing, the narrow valve angle and the TSCC system all enter into the picture. The Suzuki’s cam timing opens the intake valves at 32° BTDC and closes them at 56° ABDC; while the exhaust valves open at 64° BBDC and close at 24° ATDC. Thus the Suzuki has 268° of intake duration and an identical 268°of exhaust duration. For comparison, the Honda’s intake valves open and close at 5° BTDC and 35° ABDC while the Honda’s exhaust valves operate at 35° BBDC and 5° ATDC, for intake and exhaust durations of 220° in each case.

The Suzuki’s valve guides don’t protrude into the ports as far as the Honda’s do, barely entering the ports at all.

The advantages of narrow valve angle and the TSCC system meant that Suzuki engineers could get good flow while using smaller valves. Smaller valves meant that the combustion chamber could be more compact, which allowed the use of the flattop pistons, which contribute to the effectiveness of the TSCC design. Smaller diameter valves are also lighter valves, and since the Suzuki’s valves are in fact shorter than the Honda’s, they are lighter still.

In a normal dohc engine layout, a narrow valve angle would add to the height of the engine, since moving the valves closer

to a vertical position would move the camshafts—which normally are located above the valves and which usually activate the valves by pushing down a bucket fitted over the valve stem and valve spring— toward the centerline of the head and thus farther from the crankshaft. Moving the intake and exhaust cams closer to the cylinder head centerline could also create problems in locating cylinder head studs. If the cams were located over the studs, the camshafts would have to be pulled by a mechanic before the cylinder head could be removed or retorqued.

But in the case of the new Suzuki, the camshaft lobes push against cam-follower/rocker arms which open two valves each via conventional adjustable tappets. The cam followers pivot on shafts located below the cams, and have forked ends, one fork for each valve in a particular set of intake or exhaust valves. An oil orifice located on the pivot sleeve of each rocker arm squirts oil onto the cam lobe. In the case of the intake cam, the oil is squirted onto the trailing edge of the lobe as it passes off the cam follower pad. In the case of the exhaust camshaft, the leading edge of the cam lobe is sprayed with oil just before it contacts the cam follower pad.

Excess oil on the exhaust cam lobe can run into a channel down the middle of the exhaust cam follower pad.

Because the valves are operated through the cam follower/rocker arms, the camshafts themselves are offset enough to hold down engine height in spite of the narrow valve angle, and don’t get in the way of cylinder head stud placement. Movement at the follower pad is multiplied by about a factor of two at the valve, so the cam lobes are smaller than usual.

Since the valve springs aren’t contained within the buckets found on most dohc engines, the springs are better cooled. And the most obvious advantage of using the cam follower/rocker arm system is that home maintenance is simplified, requiring neither special tools nor a supply of varying thickness shims to adjust the valve clearances.

Suzuki engineers felt that the advantages of the cam follower/rocker arm system offset its major disadvantage, that of increased reciprocating weight. In theory, any addition in valve train weight makes valve control more difficult at very high rpm and can lead to valve float. But part of the weight gain from the rocker arm assemblies is offset by the use of smaller diameter and shorter—and thereby lighter—valves in the Suzuki design. Most dohc engines locate valve lash adjustment shims on top of valve buckets, the large shims contributing to the weight of the buckets themselves. In the Suzuki system, there are no buckets and shims, again helping to offset the weight gain of the cam follower/rocker arms.

The new cylinder head has more air cooling tunnels underneath the camshafts and doesn’t have the small cast head scoop found on earlier GS models.

The camshafts are driven by a conventional roller chain with flat link side plates instead of scalloped link side plates. The cam chain tensioning system is similar to that used on earlier GS Suzukis, but lacks the roller located between the intake and exhaust camshafts on the 1976-1979 GS750. The automatic cam chain tensioner remains essentially unchanged, and works well as long as the stock 9500 rpm redline is observed.

Suzuki's decision to change to a plain bearing crankshaft in the GS750 was probably made because a one-piece plain bearing crankshaft is stronger and mechanically quieter than a built-up, multi-piece roller-bearing crank. Anybody wanting to retain reliability when pumping much additional horsepower into a four-stroke Suzuki engine has had to weld the crankshaft where the throws are press-fit into adjacent counterweights, and where the primary gear was press-fit into adjacent counterweights, and where the primary gear was press-fit to the crankshaft itself. And even Suzuki engineers working with Pops Yoshimura have been unable to make a crankshaft last an entire 24-hour endurance race despite experiments with different main and rod big-end bearing cage designs and materials. But while the new forged crankshaft should be as indestructible as similar Honda cranks have proven, now engine builders will have to instantly change connecting rods if their hopped-up engines make much additional power.

Suzuki designers elected to switch from the earlier GS750’s straight-cut gear pri-> mary drive to a helical primary drive for the 1980 model, primarily to reduce primary gear noise. The primary drive ratio was also changed, from a 46 tooth crank gear and a 99 tooth clutch gear (2.151:1 ) to 43/93 (2.162:1 ). Since the primary drive is located adjacent to the number three cylinder's counterweight, it couldn’t be machined from a blank forged as an integral part of the crankshaft. So Suzuki engineers decided to thread the large-inside-diameter gear over the cut-down number four cylinder crankshaft webs, press the gear in place onto a shoulder, and bolt the number four cylinder counterweights in place.

The clutch used in the 1980 GS750 is nearly identical to the 1979 model clutch in basket and hub dimensions and construction, but the drive plates are 0.2mm thinner and the driven plates 0.4mm thicker.

The transmission is the same conventional five-speed used in earlier GS750s. and final drive is #630 roller chain with oring seals.

Ignition is Suzuki’s new' electronic inductive system using a conventional mechanical advance. The 1980 GS750 is fitted with four 32mm CV Mikuni carburetors. But while the nominal size of the carburetors is 32mm (measured at the point where the carbs mount on the rubber intake stubs), the carburetor bore is actually ovalshaped at the point where the slide moves, measuring 30mm x 25mm.

While discussing the components of a new motorcycle is fascinating, what really counts is how those components work when assembled. And in overall performance. the GS750 engine is a masterpiece. It’s difficult to say in absolute terms whether the GS750 makes more power than the CB750F Honda, and if so. how much, but the fact that the GS750 weighs 10 pounds more than the 1980 CB750F and still does the quarter mile 0.21 sec. quicker with 1.78 mph more terminal speed seems to indicate that the highergeared Suzuki has more power.

A more accurate appraisal w ith the same conclusion comes from a look at the acceleration data obtained from the Cycle World on-board computer equipment. The 1980 CB750F tested in the November. 1979 issue, for example, accelerated from 0-30 mph in 1.6 sec., from 0-60 in 4.4 sec., and from 0-90 in 8.5 sec. The GS750 beat the Honda at every point on the acceleration chart, accelerating from 0-30 mph in 1.5 sec., from 0-60 in 3.6 sec. and from 0-90 in 7.6 sec. In low-end, mid-range and high-rpm power-on-the-ground the Suzuki has the Honda beaten and will outaccelerate it despite more weight and taller gearing. (The Suzuki’s overall top gear ratio is 5.67:1 compared to the Honda's 5.81:1; the Suzuki turns 4328 rpm at 60 mph in top, the Honda 4573 rpm at the same road speed.)

That extra power is the end result of the Suzuki’s technology, technology which puts more fuel into the cylinders and burns that fuel in an efficient and controlled manner. Besides delivering more power, the Suzuki doesn’t detonate even on regular fuel in low' rpm. high-load situations, a problem which plagues the Honda on hot days even when premium is used. And the Suzuki delivered 51.5 mpg on the Cycle World mileage test loop, a mixture of city and open-highway riding. It’s important to note that no special effort was made— beyond staying close to posted speed limits—on the loop to increase mileage. Yet the Suzuki becomes the most economical 750cc Four, besting the previous record of 48 mpg set by the 1980 CB750F.

The 1980 GS750 owes much of its great improvement in gas mileage (the older

GS750 got 45.2 mpg on the same test loop) and all of its improved cold-starting ability to its new CV carbs. The GS750 started quickly when cold and could be ridden off almost immediately without throwing a staggering fit. Grabbing full throttle off idle 10 seconds after starting the engine didn't work real well, but just about anything less than that would send the Suzuki happily down the road at partial choke.

The GS wasn’t as good as the CB750F in cold-start performance, especially when the throttle was opened off idle, probably> because the GS doesn’t have an accelerator pump like the Honda does. The Suzuki also had more of a flat spot caused by lean carburetion than did the Honda under certain conditions. With the engine good and hot, low-load, steady-state riding at slow road speeds and small throttle openings produced bucking and coughing. Riding down a residential street at 4000 rpm (about 25 mph) in second gear was sure to produce the lean condition. The answer is to upshift to the next higher gear to load the engine.

The transmission, while not shifting as lightly as the transmissions of several Hondas, also didn’t have their peculiar tendency to jump out of or miss altogether certain gears. The Suzuki took more pressure to shift but engaged each gear more positively. The clutch, on the other hand, isn’t as good. When we first laid eyes on the GS750 and saw that the clutch cover and actuating system matched that of the GS1000, we thought that the new 750 had the 1000’s bigger clutch. A good sign for racing and stoplight GPs. we thought. Then we learned that the clutch hub and basket were unchanged and only the plate thickness, previously mentioned, altered. Maybe the thickness changes would be an improvement, we thought.

Wrong.

The 1979 Suzuki's clutch survived 18 banzai runs at the dragstrip plus a couple of road races before starting to slip. The CB750F made 10 passes before its clutch went up in smoke.

The 1980 GS750 made eight runs on its first clutch and four on its second clutch before slipping. Experimenting by installing Barnett heavy-duty clutch springs in the second stock GS750 clutch did nothing to cure the problem—after four runs, the clutch was junk, the friction material worn completely off two drive plates and the corresponding steel driven plates scarred and blue from the heat of slipping against the drive plates.

Then there is the chassis. The frame is closer to the GS1000 frame than the previous GS750 frame, and has a 60.5 in. wheelbase compared to the earlier GS750’s 58.7 in. and the CB750F’s 60 in. The 1980 swing arm is an inch longer between the swing arm pivot and the lower shock mount, increasing shock laydown angle from 19.5° to 26.5° from vertical, while shock length remains the same at 12.67 in. Rake is increased from 27° to 28° and trail reduced from 4.21 in. to 4.06 in. The 1980 forks are the leading-axle forks first seen on the 1979 Suzuki Low Slinger semi-choppers.

Comparing shock springs from a 1979 GS and a 1980 GS on a spring rate tester revealed that the new GS has 110 lb./in. single-rate springs (compared to the older GS750’s 115 lb./in. springs. Combined with the reduction in effective spring rate caused by increasing the mounting angle of the shocks, the new GS750 has much softer rear suspension than the original GS750 did. This means a lower ride height and less useful wheel travel under most conditions.

When riding solo, the Suzuki had the most comfortable interstate highway ride of any machine in memory, doing an excellent job of absorbing concrete freeway expansion joints, Bott’s Dots lane markers and other road irregularities. Along with the excellent seat and good seat/pegs/bars relationship, this makes the GS a real dreamboat on the straight freeway.

But the rear shocks would bottom on dips, holes in the road and even driveways at moderate speeds. Above 75 mph even shallow depressions in the road surface used all the travel, regardless of pre-load setting. Riding with a passenger would make the shocks bottom at legal speeds on relatively rough sections of freeway.

The soft rear suspension compresses when the bike is pitched into a turn, creating a transient response characteristic that convinces the rider that the rear end wants to come around or that the rear wheel is sliding sideways. Since the suspension compresses at turn entrances, ground clearance suffers, with the centerstand grounding instantly, followed by the pegs. As the centerstand feet wear away on the slides, the footpegs touch down, followed by the sidestand mount bracket on the left.

Suzuki has actually gone to extraordinary lengths to tuck in the exhaust system and to make the engine narrower. The 1980 GS750 engine is an inch narrower overall than the 1979 version, thanks to a more compact—yet more powerful. 230 watts, vs. 196—alternator set more deeply into the cases. But the soft suspension negates the gains of tucked-in-pipes and narrower cases.

After grinding and bashing our way through road dips and around canyon corners. we stripped the stands and turn signals off the GS750 and headed for an ARRA race at Riverside Raceway in California. There, entered in the 750 Production class (which allows internal engine modifications, accessory suspension components and racing tires) the GS met up with other “stock” machines as well as modified production machines.

The GS was sixth or seventh off the starting grid but second out of the second turn in the fast Riverside esses, thanks to sheer horsepower. But at the first relatively nice slow turn—turn six—the advantage gained through the use of power in the fast sections was lost in a shower of sparks. With the rider's knee on the ground and the right footpeg and pipe heat shield brackets dragging, modified KZ650 Kawasakis and stock CB750Fs were able to motor right around in mid-turn. It was the same at the downhill turn seven, a left hander which again had the rider's knee> on the ground and the GS dragging peg and this time, sidestand bracket. Once the rider is hanging off as far as possible and the bike is leaned over as far as it will, maximum cornering speed is attained. With the GS. any attempts to go faster put the bike sideways, especially when the rigid sidestand bracket lifts the rear w heel. (Since the 1980 GS750 frame’s sidestand bracket is welded on instead of being bolted on as in 1979 it cannot be easily removed.)

When accelerated out of bumpy turns, the GS pogos and wobbles as the shocks compress and rebound. The rider must show restraint with the throttle or find himself sideways.

It can be argued that a set of accessory shocks and stiffer springs could make the GS750 a new bike as far as sporting applications go. And we're inclined to believe that a set of 90/125 progressive springs would retain the excellent response to small bumps and the comfortable highway ride now shown by the GS750. yet alleviate its soft-suspension-related problems in corners. But strictly speaking this is a test of a stock motorcycle as delivered to the consumer, and as such, the Suzuki hasn't got the chassis (since chassis includes suspension) to match its motor.

What it does have to match its motor is brakes. The Suzuki's are simply the best in motorcycling. The stopping distances alone are worth noting, 123 feet from 60 mph at our usual test location, compared to a 750cc average of around 140 feet. More important is the feel of those brakes, and the motorcycle's controllability under braking. The Suzuki is not only easy to stop hard time after time, but the rear wheel doesn’t hop or swerve even when locked, and is more resistant to locking than previous GS brakes.

The brake discs have a series of oblong slots which remove grit from the pads and prevent the deep scoring often found on brake discs. Running a fingernail over the discs on the 1980 GS and comparing the smooth feel to the rough surface of a 1979 GS750's brake discs is amazing.

The 1980 GS750 also has an excellent headlight, a quartz halogen rectangular unit which proves that motorcycle headlights don’t have to be too anemic for safe riding at anything more than 45 mph. On the other hand, the single horn still isn't loud enough to deal with dozing highway drivers.

Instead of a reserve setting on the petcock. the new' GS has a fuel gauge. Several traditionalists on the staff (that means guys who have been riding bikes for 10 or 20 years) felt uncomfortable trusting the gauge, which actually seemed fairly accurate.

Nobody can argue that the GS750 doesn’t look different, although one wag insisted that the headlight instrument housing was inspired by a 1965 Honda Dream. The shape of the headlight, gas tank, and tail section/taillight combined with the CB750F-style side panels and chrome trim to make some staff members wonder what happened to the good old days of clean, uncomplicated lines w ithout gimmicks. But then traditionalists could probably combine GS750E parts with GS750L parts and come up with a decent looking bike if they couldn't stand the stock 750E’s looks.

And the street charger could bolt on some MX Fox shocks with S&W 125 lb. straight-wind or maybe 90-125 progressive springs and pretty much solve the handling problem (although he could buv a CB750to start with and not have a handling problem).

But one thing that nobody will have to worry about or work on is the engine, because right now the 1980 GS750 is the strongest, meanest, baddest. most powerful 750 on the straightaways of America. S

SUZUKI

GS750ET

$2799