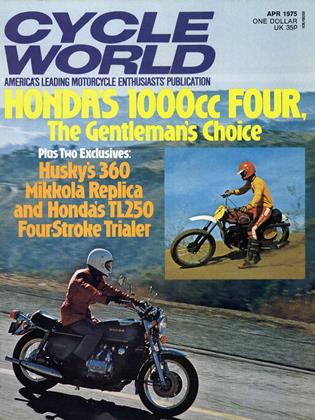

ON HELMETS AND THEIR STANDARDS

UP FRONT

Helmets are now mandatory for motorcyclists in most states. Soon they may be universally required in this country. But the helmet industry has some standardization problems that make it difficult for the first-time buyer to make an intelligent choice. The following editorial by Joe Parkhurst, publisher of CYCLE WORLD, will help those of you in this predicament.—Bob Atkinson.

IVAN WAGAR is a name near and dear to many CYCLE WORLD readers. The editor of CW for more than five years, Ivan became our director of governmental and public relations in 1973. Ivan left us last year and has taken the position as president of the Safety Helmet Council of America. Almost as legendary as Ivan’s editorship of CYCLE WORLD is his service to motorcycling in general. He has held positions in the National Motor Vehicle Safety Advisory Council, Motorcycle Industry Council, American National Standards Institute, Society of Automotive Engineers, the American Motorcycle Association, and several other non-paying voluntary organizations.

One thing that Ivan campaigned for for many years—if there had to be mandatory helmet laws—was a set of standards to be met by all helmet makers. Some standards did exist and all reputable makers of helmets adhered to them. Many others, those you might call more profitoriented, never even bothered. At one time, helmet makers who really cared had to stick so many approval labels in their helmets that there wasn’t room for the lining.

In May of 1973, Congress decreed that a helmet was part of the vehicle equipment, not an accessory; and the Department of Transportation announced to the helmet industry that a Federal Motor Vehicle Safety Standard was being established, to which all helmets manufactured after that date would have to conform. Anybody who had been watching what was going on wasn’t surprised by this development; but some people in the industry hadn’t been paying attention or weren’t really listening.

A few manufacturers agreed with the standards described in a weighty document called the Preamble to Motor Vehicle Safety Standard Number 218, or just plain 218 among friends. Ivan, as a member of the NMVSAC, agreed with the standard. It was just 10 years late in coming. The proposed standard was similar to those most in the industry were using, despite the fact that the American Association of Motor Vehicle Administrators, the Motorcycle, Scooter & Allied Trades Association and the American National Standards Institute (remember their familiar Z-90.1), all had separate standards. Hell, even New York state had one of its own, not to mention the Snell Foundation.

Complications began to arise because each helmet maker was doing his own testing; and adherence to the proposed standards was entirely self-policed. Manufacturers obtained certification at any one of several independent testing laboratories, to meet any of the several standards extant. Being self-policing also meant that makers so inclined could produce inferior products; afterall, who was to know? They were doing their own testing, remember?

I must point out here, though, that the reputable firms were indeed sampling production and satisfactorily meeting the standards. . .as they still are. The Department of Transportation, the fearsome federal body responsible for enforcing the Traffic Safety Act of 1966, was just as confused as you must be at this point.

D.O.T. solicited sample helmets from all of the members of the SHCA and subjected them to testing for compliance to the federal helmet standard. Here, the story really gets interesting. They requested bids from various laboratories and accepted the Southwest Research Institute in San Antonio, Texas, as the firm to do the job. Southwest did what it was asked to do. Disaster!

The problem arose from the fact that Southwest was using different equipment than what the manufacturers had been using in their own facilities. Mind you, the criteria for the tests was the same, as was the general description of what the tests were to do.

Not being a technical editor, I am not going to go deeply into what those differences in machinery were. I will say only that it amounts to the way a metal weight, shaped like a human head and with a helmet mounted on it, is dropped in a guided free fall onto an anvil. The weight has a sensing device in it that transmits the G forces and time duration onto an oscilloscope. A wave form is created on the scope that can be photographed. The form indicates two things: the force created by the fall, and the duration of the impact in milliseconds.

The Southwest device guided the form with rigid rails and the frame was controlled in its descent by little wheels. The industry had been performing the same test for years, but their frame was guided by wires. It seems that these wires flex a little—about six degrees—on impact, absorbing some of the energy. Enter the SHCA once again. They have filed a petition for judicial review and hope to get things straightened out and put an end to the confusion.

For many years, the battle has raged between the proand anti-helmet-law people. CYCLE WORLD has in recent years taken the antiposition. We still don’t like anyone legislating us to protect ourselves. But, we are losing. Helmet laws are in effect in nearly every state, with California being the strong hold-out to the end. With the enactment of the Traffic Safety Act, I’m afraid our days are numbered in California, too. We will still oppose it, of course, but I haven’t much faith in what will happen.

Personally, I won’t ride around the parking lot without a helmet. I read a quote in a magazine not long ago from a woman rider. She said a helmet is not a matter of freedom; it’s a matter of plain common sense. I couldn’t agree more. I also read an opinion that the helmet industry was fully behind compulsory use laws. No helmet maker with integrity was, I can assure you.

(Continued on page 78)

Continued from page 4

In the future, makers of helmets are going to have to comply with the standards or they could be subject to recalls of their products. It is one thing to force Ford to recall a few thousand cars to replace a clip, spring, mounting system, etc. for a few dollars per car. It is quite another to require a helmet manufacturer to recall thousands of them. He has no choice but to destroy them. Extremely costly, to be sure.

Effective April 1, 1975, the Safety Helmet Council of America will adopt a quality assurance program for its member firms. A stickie in the helmet will not, as in the past, say that the helmet is “certified.” What the program will consist of is technical assistance to the makers in checking incoming parts such as chinstraps, snaps, liners, cloth, etc. It will also help them keep records of these components in what is really a complex system called a helmet. Should a recall be forced, the maker will have documentation, not excuses.

This will create a uniform policing system that will have far-reaching benefit to the helmet user. He will know that the maker of a helmet bearing the SHCA stickie is taking part in a substantial safety program. If that sounds like a plug for the Council and its members, you’re damned right it is.

The reason is simple; the Federal compliance testing system is a slow process. By the time they get hold of a helmet, go through the complex and lengthy testing procedure, notify the maker, and demand recall, up to 18 months can have gone by. What this means is glaringly obvious; during that period of time, a helmet manufacturer can go right on selling thousands—in some cases millions—of helmets that just might not be adequate. Council members can choose one of four independent laboratories to check a maker’s product to see whether it conforms to the federal standards. The Council can then, if necessary, help the maker get his product up to snuff.

If you’ve got any questions regarding all of this, you can contact Ivan Wagar at the new SHCA headquarters at 9841 Airport Blvd., Los Angeles, CA 90045.

View Full Issue

View Full Issue