BUILD YOUR OWN TAILLIGHT MONITOR

NO COMPLEX ELECTRONIC CIRCUITRY IS NEEDED. THE MAGIC OF FIBER OPTICS MAKES THIS PROJECT A SIMPLE, ONE-HOUR JOB.

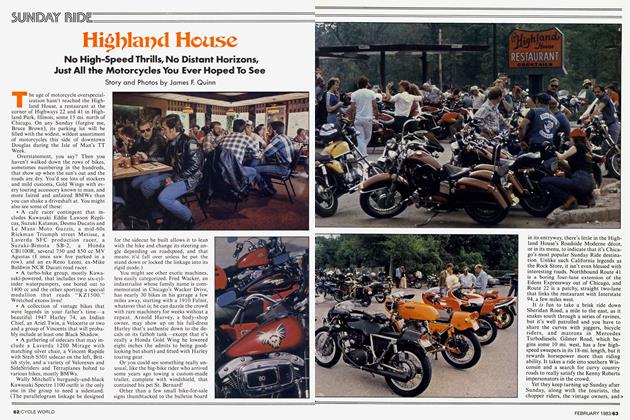

James F. Quinn

IF THERE'S anything that sends chills up my spine, it's the thought of riding in heavy traffic, surrounded by hulking, aggressive cars, without knowing that my taillight or brake light has blown out. Car drivers tend to overlook motorcyclists even in broad daylight, and when I'm surrounded by them at night, unable to use the acceleration and braking built into my Triumph Metisse, I want to make sure that my rear lights are working so the tailgaters will stay off my back.

That’s why I installed a fiber optics taillight monitor.

The idea isn’t new. General Motors has offered light monitors as options on some of its cars for several years. But Eve found fiber optics systems to be perfect for motorcycles—they’re simple, lightweight, and require no electrical hookups or moving parts that might fail because of vibration.

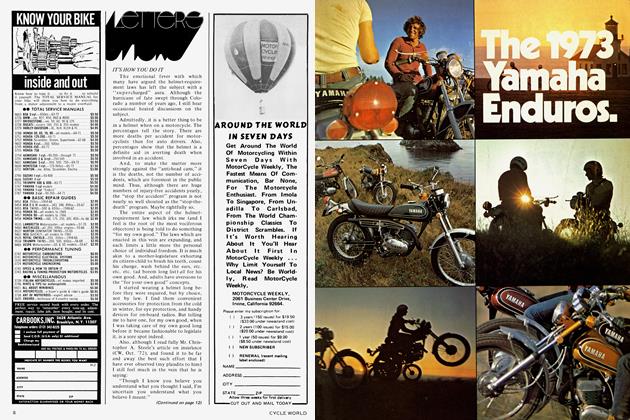

A taillight monitor is especially useful for a rider carrying a passenger or for a “cafe racer” who has fitted flat bars or clip-ons. In either case, it’s difficult to see your taillight from your riding position.

To make your own monitor system, you’ll need two acrylic terminal lenses and a strand of plastic-coated fiber optics light guide that’s long enough to run from your taillight to your headlight shell or your instruments, wherever you choose to install your monitor lens.

American Science Center, Inc., at 5700 N. Northwest Highway, Dept. CW-2, Chicago, IL 60646, is my source for these materials, though they may be available in hobby shops in your own community.

There’s only one drawback to fiber optics materials—they’re rather expensive. American Science Center sells fiber optics light guide strands for from 50 cents (for a 16-fiber strand) to 65 cents (for a 64-fiber strand, the size I used) per foot, and you’ll probably need at least 6 ft. (I bought 10 ft. and gave the unused portion to my wife, who stripped off the plastic coating, separated the individual fibers, and made a fiber optics lamp.)

The terminal lenses sell for $3.75 for an envelope of five assorted shapes. Unfortunately, American Science Center doesn’t sell them individually.

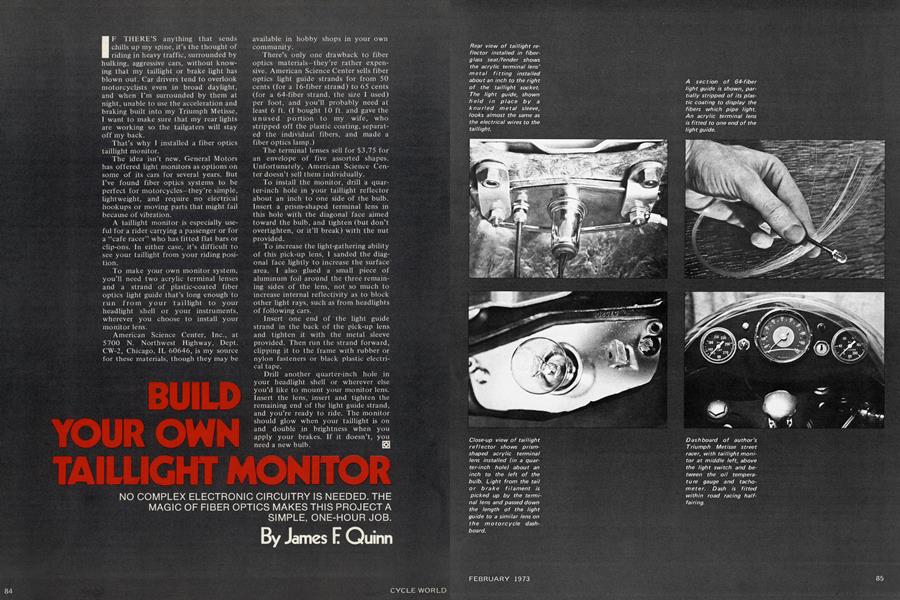

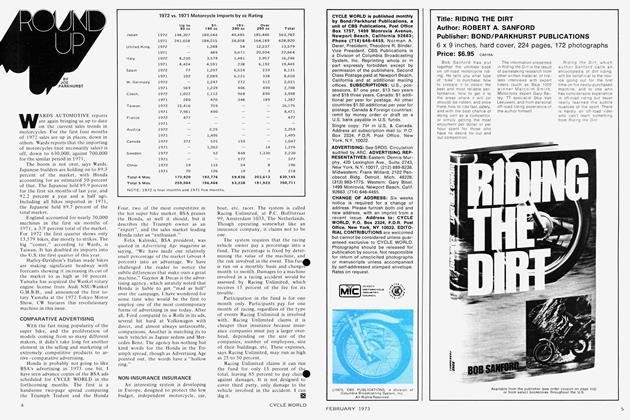

To install the monitor, drill a quarter-inch hole in your taillight reflector about an inch to one side of the bulb. Insert a prism-shaped terminal lens in this hole with the diagonal face aimed toward the bulb, and tighten (but don’t overtighten, or it’ll break) with the nut provided.

To increase the light-gathering ability of this pick-up lens, I sanded the diagonal face lightly to increase the surface area. I also glued a small piece of aluminum foil around the three remaining sides of the lens, not so much to increase internal reflectivity as to block other light rays, such as from headlights of following cars.

Insert one end of the light guide strand in the back of the pick-up lens and tighten it with the metal sleeve provided. Then run the strand forward, clipping it to the frame with rubber or nylon fasteners or black plastic electrical tape.

Drill another quarter-inch hole in your headlight shell or wherever else you’d like to mount your monitor lens. Insert the lens, insert and tighten the remaining end of the light guide strand, and you’re ready to ride. The monitor should glow when your taillight is on and double in brightness when you apply your brakes. If it doesn’t, you need a new bulb.

View Full Issue

View Full Issue