THE SERVICE DEPT

JODY NICHOLAS

PERFORATED STEEL BAFFLES

Last year I bought a late 1969 Honda CL450. It has accessory “TT” style header pipes and reverse-cone megaphones with removable perforated steel baffles. A few months ago, the front cam chain sprocket-guide assembly disintegrated, leaving only the two composition rollers and the axle for the main sprocket. I completely dismantled the engine, cleaned it out, and when I reassembled it I installed 475cc HC pistons and Weber track cams. I changed the main jets from 130 to 140. Now my problem:

(1) Do you have any idea why the cam chain guide sprocket apparently self-destructed? I’ve always adjusted it as per factory manual instructions.

(2) I really enjoy its new personality but have a real snag in the exhaust system. It runs like a jet with the baffles removed, but won’t rev cleanly past 6 grand with them installed. You can well imagine the noise with them removed (In fact it’s really not all that quiet with them installed!). I don’t mind the noise, but your “less sound’’ campaign has really been getting to me. I love the sport, and am well aware that the ability of my exhaust system to rattle windows a block away and cause cardiac arrest in the hapless motorists I pass does it no good at all. Can you recommend a muffler system which will mellow things a bit, yet still allow the engine to perform as it is now equipped to?

TSgt Herbert J. Mertel Auburn, Ala.

There are several reasons why the cam timing chain and/or guide sprockets fail on Honda 450 DOHC machines. You neglected to state how many miles your CL450 had on it when the guide sprocket failed, and there’s no way 1 have of knowing how the machine was ridden and maintained before you bought it.

The most common reasons for failures in that area are (1) the chain was set too tight, (2) the engine had a great number of miles on it, (3) the engine had been seriously overheated during its life, weakening the guide wheel, or (4) some sort of additive had been put in the oil which adversely affected the guide wheel rubber-type composition. Honda recommends that only a highgrade petroleum-based oil be used, and warns against the use of additives of any sort.

Your Honda won’t run properly with the perforated steel baffles because of the excessive back pressure they cause. 1 don’t have the technical information on the Weber track-grind cam you installed, but it’s probably pretty “wild,” needs a much smaller amount of back pressure, and is probably designed to run best with straight-through exhaust pipes or with a properly designed reverse-cone megaphone.

However, noise is a big disadvantage with either of these two systems and some sort of muffling device must be fitted to prevent rattled windows and cardiac arrests, to say nothing of citations from the police.

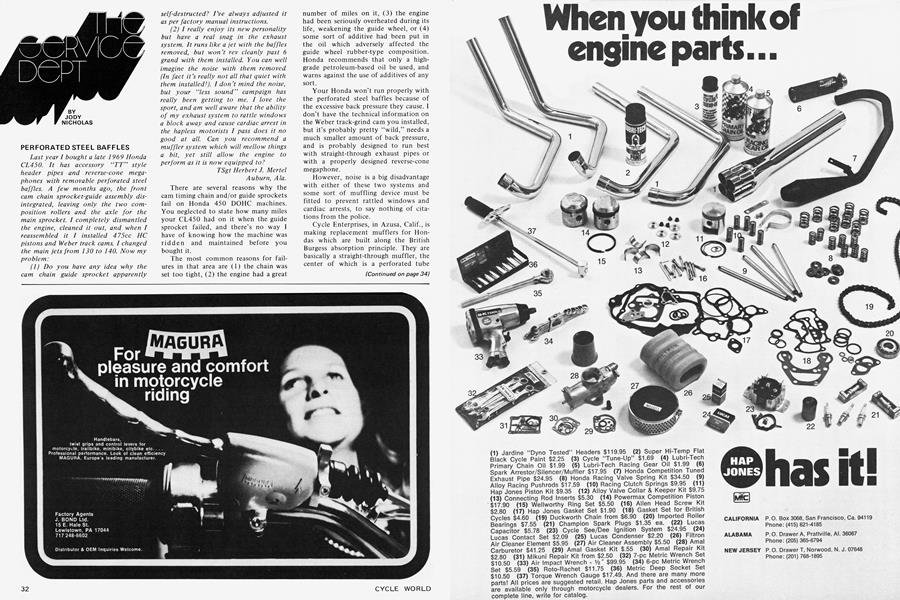

Cycle Enterprises, in Azusa, Calif., is making replacement mufflers for Hondas which are built along the British Burgess absorption principle. They are basically a straight-through muffler, the center of which is a perforated tube surrounded by fiberglass packing. This method of exhaust noise reduction is widely employed and is highly effective. The Cycle Enterprises mufflers sell for about $20 each and are available from the distributor, Long Beach Honda, 5105 Atlantic Blvd., Long Beach, CA 90805.

(Continued on page 34)

Continued from page 32

If you have increased the effective “valve spring pressure” by preloading the torsion bar “valve springs” to lessen the possibility of valve float, you can expect shorter valve train component life. Any time you “hop up” an engine you shorten its life somewhat.

NOT ENOUGH SPRING?

My bike is a 1971 650 Triumph TR6R Tiger. My wife and I enjoy road riding and with a combined weight of about 350 lb. we bottom the shocks. I would like suggestions of what can be done to get a smoother ride.

Lao Stancer Redwood Falls, Minn.

I assume you are aware that the rear shock absorber spring’s stiffness may be increased by turning the cam at the bottom of each shock. There should be a C-spanner in your toolkit for adjusting the cams. If not, you can put a rag around the cam to protect the paint and use Channel-lock pliers to rotate the cam.

Your machine should be fitted with 100-lb./in. springs which are color coded green/green, and have a fitted length (with the adjustment cam in the lowest position) of 8.4 in. You will find three splashes of paint on the springs coils to identify the spring rate. The outer two splashes (which is the primary color) will be the same color, and the center one (which is the secondary color) may or not match, depending on the spring.

If you have a chrome-plated spring, you’ll have to have the spring rate measured if you’re not sure, as they may have no identification. The Girling part number for the 100-lb./in. chromeplated spring for your machine is 64543708.

Heavier Girling springs that may be fitted in lieu of your springs are as follows: Girling part number 64544621 is a chrome-plated spring with a 126-lb./in. rating; Girling part number 64543820 is a 150-lb./in. spring and is not available with a chrome-plated surface. It has a color coding of blue/green. These spring rates are all predicated on a fitted length of 8.4 in.

Ideally, the shocks should bottom lightly on the most severe bumps you encounter to effectively use the full travel of the shock absorber unit. [Ö]

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

August 1972 By Joe Parkhurst -

Letters

LettersLetters

August 1972 -

Departments

DepartmentsFeedback

August 1972 -

Departments

DepartmentsThe Scene

August 1972 By Ivan J. Wagar -

Competition

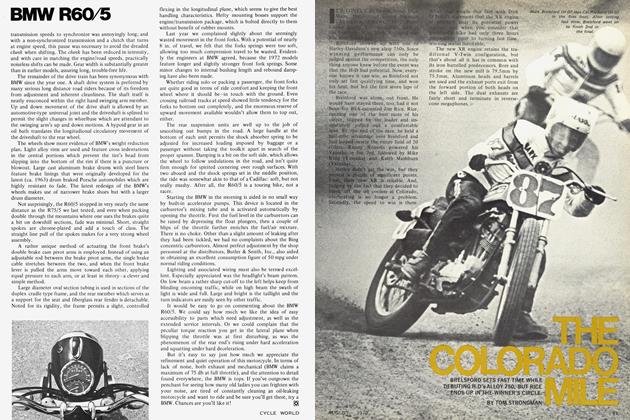

CompetitionThe Colorado Mile

August 1972 By Tom Strongman -

Technical, Etc.

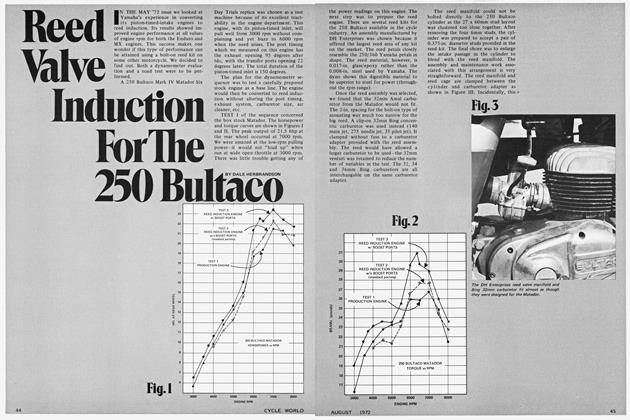

Technical, Etc.Reed Valve Induction For the 250 Bultaco

August 1972 By Dale Herbrandson