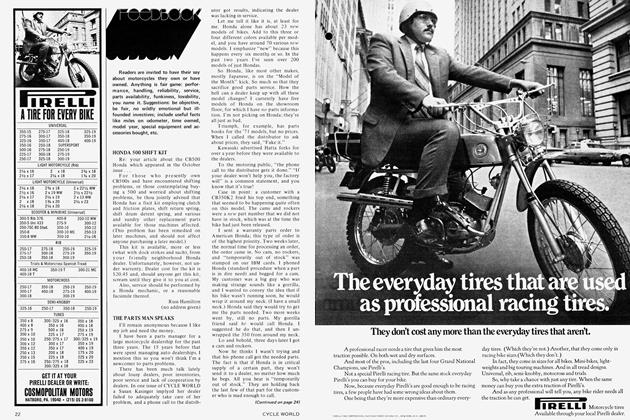

THE SERVICE DEPT

HEADLAMP SUBSTITUTIONS

JODY NICHOLAS

I thought a few of your readers might like to know about motorcycle headlamp conversion to automotive sealed beam lamps. There are some excellent reasons for converting.

1. Better availability than the standard part. If you’ve ever needed a new lamp on Sunday night out in the suburbs, you know how much easier it is to get a car headlamp. Most gas stations have a good selection.

2. Better light than the standard part. In a sealed beam headlamp, the light goes through only one layer of glass on the way out. Less light is scattered or lost. Also, darkening occurs much more slowly than a bulb-in-a-reflector assembly, which is still used on many motorcycles. Even if the reflector stays clean, the inside of the bulb picks up a layer of tungsten as the filament burns away.

3. Lower cost. Frequently, the automotive sealed beam costs less than the standard part. The lamp for my 650 Yamaha costs $8.40. A sealed beam automotive replacement costs $1.69 to $3.50, depending on where I buy.

There are two aspects to the conversion, electrical and mechanical.

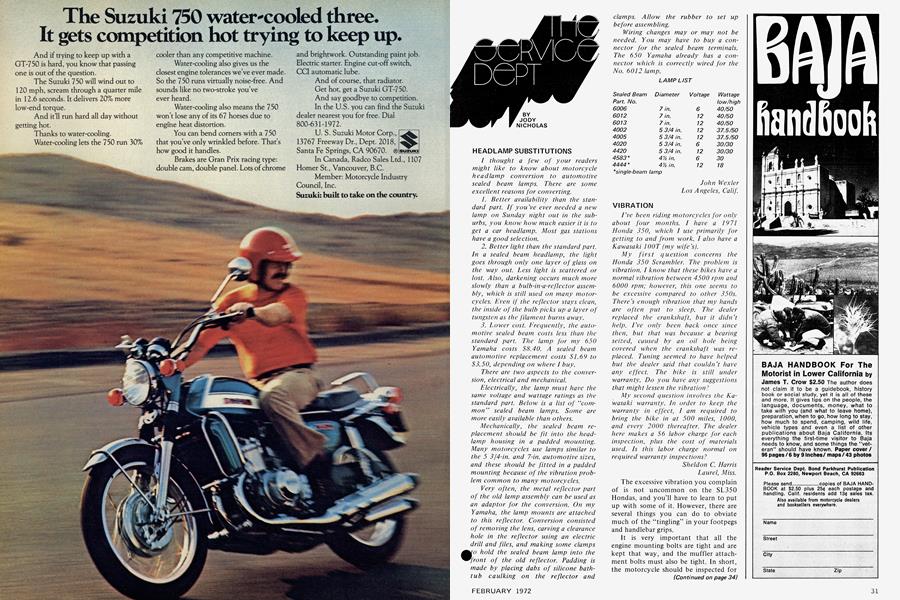

Electrically, the lamp must have the same voltage and wattage ratings as the standard part. Below is a list of “common ’’ sealed beam lamps. Some are more easily available than others.

Mechanically, the sealed beam replacement should be fit into the headlamp housing in a padded mounting. Many motorcycles use lamps similar to the 5 3/4-in. and 7-in. automotive sizes, and these should be fitted in a padded mounting because of the vibration problem common to many motorcycles.

Very often, the metal reflector part of the old lamp assembly can be used as an adaptor for the conversion. On my Yamaha, the lamp mounts are attached to this reflector. Conversion consisted of removing the lens, carving a clearance hole in the reflector using an electric drill and files, and making some clamps

I4o hold the sealed beam lamp into the front of the old reflector. Padding is made by placing dabs of silicone bathtub caulking on the reflector and clamps. Allow the rubber to set up before assembling.

Wiring changes may or may not be needed. You may have to buy a connector for the sealed beam terminals. The 650 Yamaha already has a connector which is correctly wired for the No. 6012 lamp.

John Wexler Los Angeles, Calif.

VIBRATION

I’ve been riding motorcycles for only about four months. I have a 1971 Honda 350, which I use primarily for getting to and from work. I also have a Kawasaki 100T (my wife’s).

My first question concerns the Honda 350 Scrambler. The problem is vibration. I know that these bikes have a normal vibration between 4500 rpm and 6000 rpm; however, this one seems to be excessive compared to other 350s. There’s enough vibration that my hands are often put to sleep. The dealer replaced the crankshaft, but it didn’t help. I’ve only been back once since then, but that was because a bearing seized, caused by an oil hole being covered when the crankshaft was replaced. Tuning seemed to have helped but the dealer said that couldn’t have any effect. The bike is still under warranty. Do you have any suggestions that might lessen the vibration?

My second question involves the Kawasaki warranty. In order to keep the warranty in effect, I am required to bring the bike in at 500 miles, 1000, and every 2000 thereafter. The dealer here makes a $6 labor charge for each inspection, plus the cost of materials used. Is this labor charge normal on required warranty inspections?

Sheldon C. Harris Laurel, Miss.

The excessive vibration you complain of is not uncommon on the SL350 Hondas, and you’ll have to learn to put up with some of it. However, there are several things you can do to obviate much of the “tingling” in your footpegs and handlebar grips.

It is very important that all the engine mounting bolts are tight and are kept that way, and the muffler attachment bolts must also be tight. In short, the motorcycle should be inspected for loose nuts and bolts every couple weeks.

(Continued on page 34)

Continued from page 31

The handlebars on your SL350 are mounted in rubber which helps take some of the vibration out before it reaches your hands, but if the clutch and brake levers are allowed to get loose, they will vibrate up and down and make matters worse. Have you tried larger handlebar grips like the “GT” models? They do a good job of soaking up vibration.

Your Kawasaki dealer’s service charge is well within reason. The Kawasaki guarantee reads: “Owner (at his expense) must take the motorcycle to an authorized Kawasaki dealer for periodic inspections at 500, 1000 and every 2000 miles thereafter . . .” For $6 plus parts, you’re not getting burned. Some dealers give the first service free, but it is entirely up to the dealer.

SQUEAK CURE

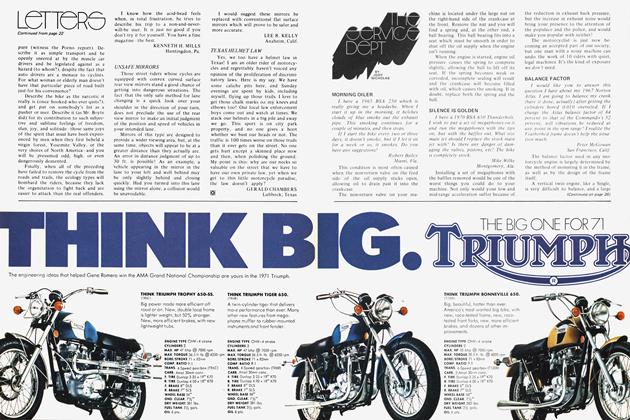

While my enduro bike does not have a disc brake, I also drive a Porsche which has four of them. One cure for brake squeak which seems to have worked for some friends of mine is to drill four or five very small holes into the face of the brake pads. In these holes insert graphite in the form of Scripto mechanical pencil lead.

The small amount of graphite released during braking, as the pads wear, reduces or cures squeaking, and doesn’t seem to reduce braking effectiveness. The fit should be close, but doesn’t have to be exact, as the closeness of the pads to the disc will keep the lead in place.

Paul Donkin Lebanon, Ore.

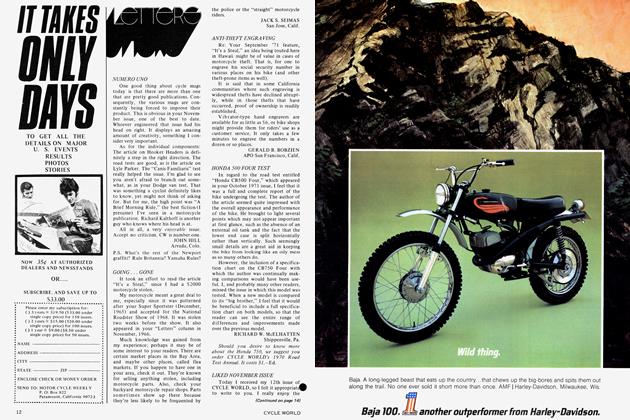

hole

BRAKE PUCK (SIDE VIEW)

BRAKE PUCK (END VIEVU

Drill holes to within 1/16th inch of brake puck width; holes should be slightly larger than the pencil lead diameter.

View Full Issue

View Full Issue