THE SERVICE DEPT

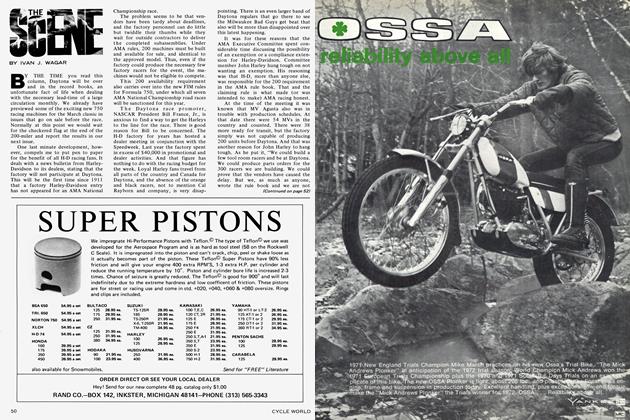

JODY NICHOLAS

BMW WOES

I need some information please. I own a BMW R69S 1969 model with frame and engine number 665937. I purchased it used at 6000 plus miles and it is a reasonably good looking motorcycle. I have made no changes in the equipment and have had it serviced and tuned at recommended intervals.

I fear, however, that the engine is a lemon. This bike floods if you look at it cross-eyed, and takes 40 kicks to start. The right jug sounds like a crap game being played inside a steel drum although compression is up to par with the left cylinder and the bike uses no oil. I change it every 2000 miles.

The starting problem is what really bugs me. I can just hang it up on a cold day. I've got the right plugs, the right timing, all electrics are fine and although I loath those two Bing carburetors, they have been carefully disassembled, inspected, cleaned, and put back together by the local dealer's BMW "Wizard." The guy ought to know what he is doing, he owns three of them himself. All I can get from him, however, is a grunt acknowledging my existence, but no answers to my questions.

What I want to know (sorry about all the prologue) is: Can a 750cc BMW engine be installed in my frame without any modifications? The reason I consider this is because of the improved carburetor design and, of course, the electric starter. If that isn't possible, can an electric starter be adapted to the 600cc lemon I'm co-existing with?

As a last resort, I'll pull that engine and rebuild it myself since I've got all of the factory manuals on it. I'd like to avoid this for at least one more year because then I'll have a second machine and won't have to sit out a season of cycling for lack of a good bike.

Dave Braum Tulsa, Okla.

Your set of problems intrigues me because probably none of them are serious. It sounds as though you take reasonably good care of your machine, but just don't know the tricks.

You say that the bike floods easily but that it won't start on a cold day. If the timing is correct and there is both a gas/air mixture and a spark occurring at the correct time, the engine should start right up. The proper procedure for starting the machine on a cold day is to press each tickler button until gas runs out of the bleed hole on the float chamber, open the throttle about a quarter turn (depending on the machine), turn on the ignition and press downward vigorously on the kickstarter.

However, the automatic spark advance unit will in time have a tendency to become stiff because of lack of lubrication and must be removed to free it up. Loosen the 6mm allen bolt and withdraw the automatic advance unit. Work it back and forth several times while applying penetrating oil to the pivot points.

When the unit frees up, apply a graphite lubricant such as Dri-Slide to the pivots. The "carrier" fluid will evaporate, leaving a film of graphite on the bearing surfaces. This drill should be repeated periodically to ensure that the timing does not become fixed, but rather advances with the engine's increase in rpm. When reinstalling the automatic advance unit make sure to press it into the magneto shaft lightly and turn it until it fits into the slot on the shaft.

(Continued on page 40)

Continued from page 38

Adjusting the float level of the carburetors should not be necessary as they are not designed to be adjusted, other than swinging the float chamber back and forth on its pivot, which will raise or lower the level only a tiny bit. If you've been running an air cleaner the carburetor slides should not be worn excessively.

The "crap game" being played in the right cylinder is probably either a broken valve spring or, more likely, a buildup of carbon on the exhaust valve stem in the "tulip" area, which will produce the same sound you described. It is caused by the heavy lead concentration of some American premium grade gasolines and, on earlier models, by the valve's inability to rotate because of the collar/keeper design. Your machine should have the latest style bits installed so I suspect that the gasoline lead is primarily at fault.

A trick that is beneficial to all BMW machines prior to the latest /5 models is to remove the cylinder heads, disassemble the valve mechanisms and obtain an 8mm tap. Using the tap, make some threads into the exhaust valve guides to a depth of one-quarter inch. This will form a small oil pocket to better lubricate the valve stems.

No, the latest /5 series engine won't fit into your frame because there is not enough room, and your R69S engine will not accept an electric starter.

LITTLE THINGS

I purchased a late model 1970 Norton Commando Roadster in April of this year, and have encountered the following minor problems with it:

I have been unable to keep the header clamps tight, even after safety wiring was done by the dealer. They will invariably loosen after 10 to 15 miles of riding. This resulted in a broken header pipe flange before I wised up and included a large pair of channel-locks in my toolkit. The constant tightening required does prove to be an irritation, nonetheless. What can be done?

The steel oil line running from either side of the cylinder head down to the lower part of the engine cracked at approximately 2500 miles. The replacement I installed has approximately 400 miles on it, and also has begun to leak where it mounts to the right side of the cylinder head. I'm certain that this is caused by vibration, but what can I do to keep this from being a constant problem?

(Continued on page 42)

Continued from page 40

I also have a problem with oil-burning. Once the engine is warmed up, it seems to load up considerably during any in-town riding. I always try to keep the rpms at around 3000 during in-town riding, as I have read that this will help keep it from overheating, but any trip across town will produce white-smokeblowing starts from every stoplight. This problem is especially evident after a long ride at freeway speeds. I have seen many two-strokes that smoke less! My dealer insists that this is due to the fact that the rings haven't seated, but the bike has 2970 miles on it, 450 miles of which were added on a trip to the Colorado River. It seems unlikely to me that the rings shouldn't have seated by now. What is your opinion?

I purchased this machine new, and have kept it in new condition. I am not mechanically inclined, but I am trying! I find I spend nearly as much time cleaning my bike as I do riding it, which is fine with me, as I waited a long time before I could afford to purchase it, and am very proud of my machine. I would appreciate any comments you might have regarding these problems.

Rick Hobson, Jr. Garden Grove, Calif.

The problems you have been experiencing with your 1970 Norton Commando have been cleared up on later models and are quite easy to fix on your machine.

A new locking ring and tab washer (part number 062412) is now being fitted to each new 750-cc Norton which prevents loosening of the header clamps. This tab washer has a couple prongs which fit in between the cylinder head fins and one which will align with a fin gap on the header pipe clamp to keep it from loosening.

The steel rocker arm feed oil line has been replaced with a flexible neoprene one (part number 062168), available from your Norton dealer. These flexible oil lines vibrate with the engine and don't break.

Oiling problems caused by improper piston rings were cured by the factory before your machine was produced, but machines suffering an oil burning problem like yours can be cured by the installation of special inlet valve guides (part number 062760) and valve guide seals (part number 062726). These valve guides and seals should only be installed on the inlet side, because the higher temperatures on the exhaust side could cause valve seizure.

LOW COMPRESSION?

I am in the process of modifying a Ducati 450 R/T. I have completed the chassis work and am now working on the engine. The stock compression ratio is around 9:1 which I would like to bring up to 10 or 10.5:1. My question is whether I can gain this by milling the head or barrel. If so, how much of a cut would you recommend?

I realize this would probably involve cutting the valve pockets out a little, but as no one is making high compression pistons for this model, it seems to be the only way to go. Would I have to alter my ignition setting after going to the high compression ratio?

Steve Pitts San Carlos, Calif

Milling the cylinder head and/or cylinder to increase the compression ratio on a Ducati 450 R/T is not recommended because of the very small clearance between the top of the piston and the edges of the combustion chamber. If you relieved the edges of the piston to increase the clearance between it and the cylinder head, you would weaken the piston. And if you relieved the outer edge of the combustion chamber you would be partially defeating the purpose of milling the cylinder head or cylinder, by removing metal instead of adding.

If you feel that you have to have more compression on your Ducati, I would recommend having the top of the piston heliarc-welded up and grind it down smooth. This, of course, is a hit or miss method because you won't know exactly what the compression ratio is until you reassemble the engine and measure it. Also, the addition of weight to the piston will probably make the engine vibrate more, or will change the point of maximum vibration.

To measure the compression ratio, turn the engine to top dead center on the compression stroke so that both valves are closed, and lean the bike over until the spark plug threads are pointing straight up so that the plug hole will be the highest part of the combustion chamber. Use a graduated cylinder to pour in a mixture of light engine oil and kerosene until the combustion chamber is completely filled and the fluid covers two or three of the lowest threads.

The capacity of your Ducati is 436cc and if you pour in approximately 53cc of fluid you should come out with:

which is your compression ratio, assuming there is no carbon on the cylinder or head.

Most of the people in this area have found a method to "wake up" their Ducatis, and that is by enlarging the inlet port and fitting a 32-mm Mikuni carburetor (such as the type found on a Suzuki T-500), and modifying the jet sizes for best performance. It has also been found that the optimum amount of spark advance is 35 deg.