Driver Jon McKibben Tells The Story Of The... 285 MPH HONDA HAWK

"THE UNFINISHED RECORD"

A CONFIDENT CREW of impressive numbers arrived at Bonneville to set a new motorcycle land speed record. A month later the same crew left Bonneville with no record, a machine with its paint job largely replaced by sanded (salted?) aluminum, and a great deal of respect for those who previously have set new records on the salt flats near Wendover, Utah.

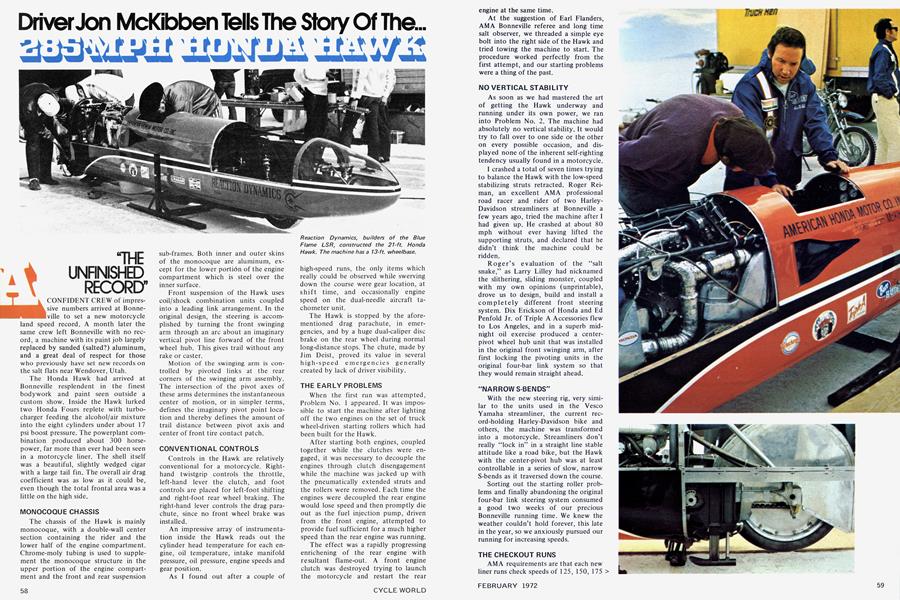

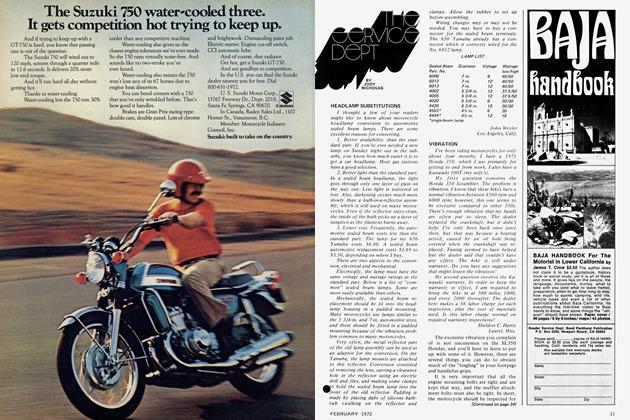

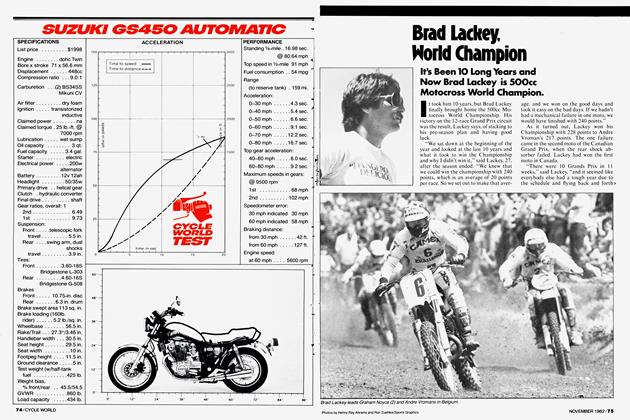

The Honda Hawk had arrived at Bonneville resplendent in the finest bodywork and paint seen outside a custom show. Inside the Hawk lurked two Honda Fours replete with turbocharger feeding the alcohol/air mixture into the eight cylinders under about 17 psi boost pressure. The powerplant combination produced about 300 horsepower, far more than ever had been seen in a motorcycle liner. The shell itself was a beautiful, slightly wedged cigar with a large tail fin. The overall air drag coefficient was as low as it could be, even though the total frontal area was a little on the high side.

MONOCOQUE CHASSIS

The chassis of the Hawk is mainly monocoque, with a double-wall center section containing the rider and the lower half of the engine compartment. Chrome-moly tubing is used to supplement the monocoque structure in the upper portion of the engine compartment and the front and rear suspension sub-frames. Both inner and outer skins of the monocoque are aluminum, except for the lower portión of the engine compartment which is steel over the inner surface.

Front suspension of the Hawk uses coil/shock combination units coupled into a leading link arrangement. In the original design, the steering is accomplished by turning the front swinging arm through an arc about an imaginary vertical pivot line forward of the front wheel hub. This gives trail without any rake or caster.

Motion of the swinging arm is controlled by pivoted links at the rear corners of the swinging arm assembly. The intersection of the pivot axes of these arms determines the instantaneous center of motion, or in simpler terms, defines the imaginary pivot point location and thereby defines the amount of trail distance between pivot axis and center of front tire contact patch.

CONVENTIONAL CONTROLS

Controls in the Hawk are relatively conventional for a motorcycle. Righthand twistgrip controls the throttle, left-hand lever the clutch, and foot controls are placed for left-foot shifting and right-foot rear wheel braking. The right-hand lever controls the drag parachute, since no front wheel brake was installed.

An impressive array of instrumentation inside the Hawk reads out the cylinder head temperature for each engine, oil temperature, intake manifold pressure, oil pressure, engine speeds and gear position.

As I found out after a couple of high-speed runs, the only items which really could be observed while swerving down the course were gear location, at shift time, and occasionally engine speed on the dual-needle aircraft tachometer unit.

The Hawk is stopped by the aforementioned drag parachute, in emergencies, and by a huge dual-caliper disc brake on the rear wheel during normal long-distance stops. The chute, made by Jim Deist, proved its value in several high-speed emergencies generally created by lack of driver visibility.

THE EARLY PROBLEMS

When the first run was attempted, Problem No. 1 appeared. It was impossible to start the machine after lighting off the two engines on the set of truck wheel-driven starting rollers which had been built for the Hawk.

After starting both engines, coupled together while the clutches were engaged, it was necessary to decouple the engines through clutch disengagement while the machine was jacked up with the pneumatically extended struts and the rollers were removed. Each time the engines were decoupled the rear engine would lose speed and then promptly die out as the fuel injection pump, driven from the front engine, attempted to provide fuel sufficient for a much higher speed than the rear engine was running.

The effect was a rapidly progressing enrichening of the rear engine with resultant flame-out. A front engine clutch was destroyed trying to launch the motorcycle and restart the rear engine at the same time.

At the suggestion of Earl Flanders, AMA Bonneville referee and long time salt observer, we threaded a simple eye bolt into the right side of the Hawk and tried towing the machine to start. The procedure worked perfectly from the first attempt, and our starting problems were a thing of the past.

NO VERTICAL STABILITY

As soon as we had mastered the art of getting the Hawk underway and running under its own power, we ran into Problem No. 2. The machine had absolutely no vertical stability. It would try to fall over to one side or the other on every possible occasion, and dis played none of the inherent self-righting tendency usually found in a motorcycle.

I crashed a total of seven times trying to balance the Hawk with the low-speed stabilizing struts retracted. Roger Rei man, an excellent AMA professional road racer and rider of two HarleyDavidson streamliners at Bonneville a few years ago, tried the machine after I had given up. He crashed at about 80 mph without ever having lifted the supporting struts, and declared that he didn't think the machine could be ridden.

Roger's evaluation of the "salt snake," as Larry Lilley had nicknamed the slithering, sliding monster, coupled with my own opinions (unprintable), drove us to design, build and install a completely different front steering system. Dix Erickson of Honda and Ed Penfold Jr. of Triple A Accessories flew to Los Angeles, and in a superb mid night oil exercise produced a centerpivot wheel hub unit that was installed in the original front swinging arm, after first locking the pivoting units in the original four-bar link system so that they would remain straight ahead.

"NARROW S-BENDS"

With the new steering rig, very simi lar to the units used in the Vesco Yamaha streamliner, the current rec ord-holding Harley-Davidson bike and others, the machine was transformed into a motorcycle. Streamliners don't really "lock in" in a straight line stable attitude like a road bike, but the Hawk with the center-pivot hub was at least controllable in a series of slow, narrow S-bends as it traversed down the course. Sorting out the starting roller prob lems and finally abandoning the original four-bar link steering system consumed a good two weeks of our precious Bonneville running time. We knew the weather couldn't hold forever, this late in the year, so we anxiously pursued our running for increasing speeds.

THE CHECKOUT RUNS

AMA requirements are that each new liner runs check speeds of 125, 150, 175 and 200 mph. A miscalculation of ta chometer speeds versus bike speeds caused my first run at 125 mph to be about 93 mph, but after that, comple tion of the required check runs was dead easy.

We experienced some speed wobble problems in the 17 5-200 mph region, so changes in front wheel pivot axis rake and trail were performed. These proved effective in removing all wobble up to a speed of about 250 mph.

At this speed the machine began oscillating at a low frequency, with enough force to move my shoulders back and forth despite efforts to brace my body back against the aluminum panel, which served as a riding seat.

I found, though, that when all sys tems were functioning properly, the Hawk would accelerate through this 250-mph wobble period surprisingly fast, and would again become stable at about 270 mph. Rather than lose more of our precious program time, I decided to fight the wobble at 250 mph and get on to some really high speeds.

THE QUICK RUNS

Bonneville 1971 was a relatively poor year for the salt. The south end of the course, all the way into the timing traps, was extremely rough. With the rigid rear end structure of the Hawk, the rear wheel spent more time in the air than on the surface. This limited acceleration caused severe shock loading on the rear drive chain (a Morse Hy-Vo unit similar to the CB500 Honda primary chain), and produced some very impressive en gine speeds as the rear tire lifted and load on the drive train was removed.

I found that I could only run a little over 26-0 mph starting from the south end of the course, because use of full throttle was impossible without in ducing wild rear wheelspin and creating the impression of accelerating a power ful motocross machine over rough ground. Those readers who are familiar with the sensation of the rear tire trying to pass on the side while skittering back and forth over bumps will probably appreciate that this becomes entirely too exciting at 250 mph. Since I also was dealing with the annoying wobble problem at the same time, you will understand why I looked forward to south-to-north runs with less than pleas ant anticipation.

The approach to the timing traps from north to south, although a mile shorter than the rough approach from the south, was a real blast. This course section was relatively smooth, and I was able to pin the throttle in fourth and fifth gears. On one run, I hit about 280 mph in a little over three miles, and was targeted for well over 300 mph when the main intake manifold feed tube from the turbocharger burst. The en gines lost their power-producing boost, but I still roared through the traps at over 289 mph for the last 2000 yards, accelerating all the way and topping 290 mph at the exit light.

NO FORWARD VISION

The sensation is impossible to ex plain. Because of some internal modifi cations to the front end, including removal of the front tire shield to improve my still-terrible visibility, I lost all forward vision at about 280 mph.

Trying to set a fast time, to improve my confidence and the morale of the crew, I kept the throttle wide open until I felt the hard bumps that signaled the far end of the timing traps. Then I pulled the drag parachute, slowed as much as possible, and fell onto the liner's side at about 150 mph. After sliding across the salt, dragging the parachute for about 600 yards, I still was as happy as a duck in water because I knew we finally had an indication of the potential of the Honda Hawk.

We tried to turn around and make a return run for the record, but a fire in the engine compartment cost too much time for rewiring, as repairing the crash damage p roved time-consuming. When we towed off on the return run from the south, the final drive chain gave up and we were through for the day.

THE PAINFUL PROBLEMS

The last 10 days are like a tragic opera. We experienced failure after fail ure, all seemingly designed to prevent us from officially certifying what we knew we had-a world record machine

We had a series of rear drive chain failures. These were traced to an unfor tunate tendency for the Hy-Vo chain to destroy itself if an extreme preload was not maintained between the rear axle and the countershaft sprocket. When we increased the chain preload well over the original design limit of 2500 lb., we failed a set of rear axle bearings and ruined the complexly machined rear axle shaft. Changing rear axle bearing lubricant from grease to oil apparently solved that problem, and we thought we were on our way.

A NEAR MISS

On November 12 we were ready to make our two quick passes for the record. I made a near-perfect run from the smooth north end of the course at over 284 mph through the measured mile, accelerating fairly hard all the way through the traps.

When we tried to tow-start from the south end, we discovered the final ulti mately crippling problem. Electronic engine speed limiter units, which we had relied upon to keep engine revs within safe limits despite the bumpy course, were totally inoperative at the 40-deg. temperatures that we experienced at Bonneville.

With no protection against severe valve float, the magnificent, bulletproof 750 Fours gave up, and the front engine plowed both valves through the piston crown in one cylinder.

Frantically searching the cloud-filled skies for a sign of one more day of running weather, the crew labored once again to get the Hawk into running condition. We almost made it, but the wind, rain and snow got to the salt flats a few hours before we could. There would be no two-way runs for the Hawk this session-our four weeks of effort would not generate a record.

"DRIVING THE HAWK: WHAT IS IT LIKE?"

IVING A MOTORCYCLE liner not only difficult. It is perhaps the most bewildering task in the world of motoring.

As the tow truck starts forward, you are aware of the beginning of a very bumpy, alternately tilting, scraping skid over the salt. The tow rope disconnect is controlled by men inside the tow truck, so we opted for a tow to about 55 mph, then disconnected before starting the Hawk engines and beginning acceleration.

When the tow rope disconnects, you feed in some throttle, making sure that the ignition switches (yes, there are two) and the main power switch are flipped on. Check the gear position indicator lights to be sure that both transmissions are in first gear (both red lights on).

When the engines begin to fire cleanly and pull hard, ease back on the throttle to control wheelspin and begin to move up into the 70-90-mph speed range where the Hawk starts to balance itself.

As soon as the Hawk starts to move with the struts and skids extended, you have to steer the vehicle around a little to center it on the black line marking the middle of the course. With the struts extended, the machine steers like a car-turn left to make the vehicle go left.

At about 70-80 mph, the machine tries to balance itself off the skids. When it feels stable, push in on the knob above the clutch lever to retract the struts. At that point, pay very close attention because this is a very low speed for a machine like the Hawk and it will try to keel over to one side.

If the machine tries to veer left and fall onto the left side, you now must steer to the left to make the machine bank right and turn right. Confusing? You should try it inside a machine where your only indication of falling over is the tilt of the tiny slit of horizon visible through the clear section of the nose cone above the front tire.

Remembering now that the only

control you have over the machine’s attitude is to turn the bars in the opposite direction from that which you wish the machine to lean and turn, build speed as rapidly as traction permits. At about 100 mph, shift to second gear, check to make sure that both transmissions have moved into the second gear slot (the third set of lights will be illuminated, the second set are for neutral), and wind on some more throttle.

Once you reach 150 mph or so, the Hawk feels fairly stable and the initial violent swerving needed to maintain balance has subsided into fairly slow, gentle S-bends from one side of the center line to the other. On up through second, third and fourth gears, and the landscape is moving past awfully fast.

Fourth gear will carry the Hawk past 240 mph, and then it’s time to drop into fifth and whistle through the traps. Again making sure that both transmissions are in the same gear before releasing the low-effort power assisted clutch lever (if two different gears are selected and the clutches released, almost instant destruction of some portion of the power train would result), you pull full throttle and try to stuff the liner through the timing traps.

The distance between timing lights, laterally, is about 80 ft. the way Joe Petrali sets them up. At 280 mph, they look about a foot apart, and you just know that you won’t be between the lights when you arrive at the traps. But, as you rapidly approach the timing section, the lights seem to move apart and you whistle through with lots of room to spare.

You stay on the throttle until you’re sure you’ve clocked your best speed. Then it’s time to bring the rig to a stop, and this is perhaps the hairiest time of all.

First, closing the throttle is disastrous. With the amount of engine braking produced by the two essentially stock Honda 750 Fours, the rear tire would skid under engine braking and the rear end of the machine will begin to “fishtail.” Never mind how I know this, smarty.

So you pull the clutch lever in and turn off the ignition switches. Now you’re flying along with just the incredible racket caused by bumps and panel resonance in the world’s fastest tin can to keep you company.

Down through the 250-mph speed wobble, and the machine again becomes fairly stable. Pay attention, though, because the Hawk tries to swerve pretty violently at random intervals during coastdown. Once you slow to about 100 mph, wild swerves are generally required to keep the liner balanced and traveling down the course.

As you drop below 80 mph, you can pull the strut extension control. Be sure, however, that the machine is balanced

in a straight-up attitude before dropping the struts. Otherwise, one strut will bang into the slot and cause a wicked bounce over to the other side. Rollover is almost sure to follow.

With the machine balanced, riding lightly on the skids, and traveling fairly straight down the course, you can begin to relax and gather the remnants of your mind. As long as you can turn gently to stay on course, do it. If the machine makes a sharp turn off-course for some reason, you let it wander a little. A hard turn with the struts down can dig in a skid and let the machine roll over. Oh, yes. Don’t forget that the machine is now traveling on two wheels and two skids and steers like a car again—no more of that reversed steering or you’ll be in real trouble.

What is it like at 280 mph on two wheels? Well, it’s a little scary, and yet there can be no more rewarding feeling in all of racing.

The world is passing by at an unbelievable rate, the machine is slowly moving from left to right and back again, controlled by your most delicate inputs to the handlebars, and you have a distinct feeling of piloting a rocket through the air. Only the fantastic noise level generated through the metal container in which you’re strapped reminds you that you are in intimate contact with some rather rough ground.

The wheels are crashing into bumps, the shell panels are resonating from the vibrations generated mostly by the tires and wheels, and in the distance eight cylinders of Honda power are howling their muted roar at the spectators.

Your view of the world from the driver’s seat is limited to a slit about 2 in. by 8 in., and this shrinks into nothing when the front end of the bike and your head both are bouncing ferociously over the rough sections of the course. When the vehicle is on smooth salt, you split the short opening with the horizon line, viewing some salt and the black course center line in the bottom half of the viewing area and a portion of some mountains in the upper half. When the horizon line tilts, you press gently on the handlebar at the low side of the tilt to right the liner and straighten your course.

If you lose the course, don’t panic. There’s very little to hit on the Bonneville salt flats. Just pull the parachute, which will jam you forward into the shoulder harness straps and slow the machine very quickly. Apply the rear brake carefully to avoid skidding the rear tire, and try to get down to a speed where you can drop the struts and come to an upright stop.

If you fall over, make sure the chute is out to prevent spinning and tumbling, and relax. You’ll stop sliding eventually, even if you don’t believe it for a long time.