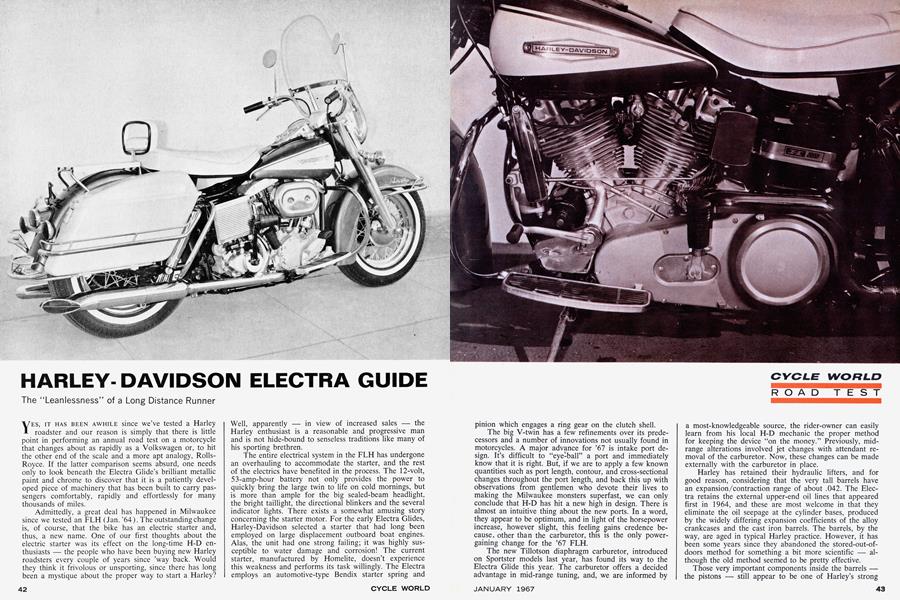

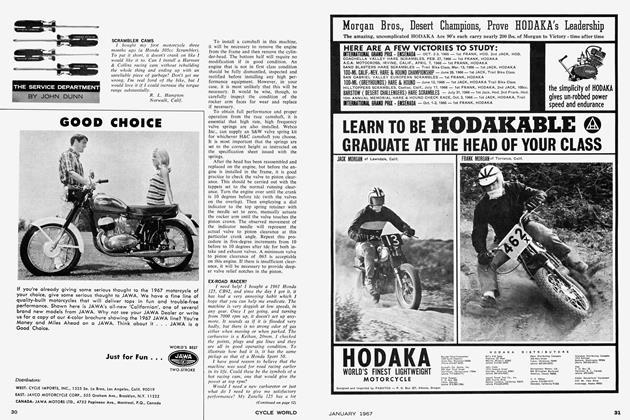

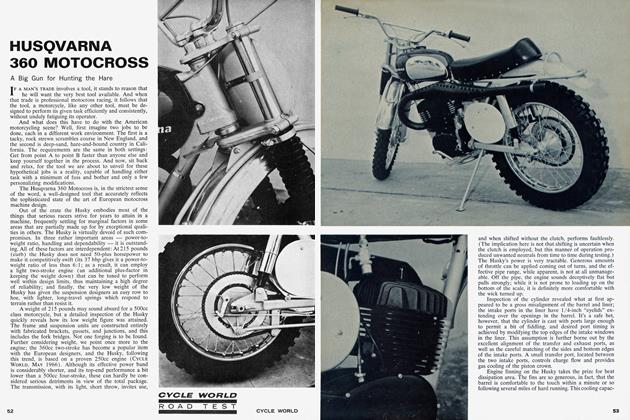

HARLEYDAVIDSON ELECTRA GUIDE

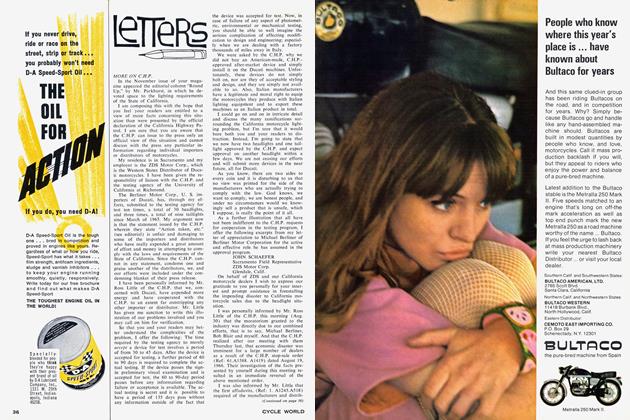

The "Lean lessness" of a Long Distance Runner

YES; IT HAS BEEN AWHILE since we've tested a Harley roadster and our reason is simply that there is little point in performing an annual road test on a motorcycle that changes about as rapidly as a Volkswagen or, to hit the other end of the scale and a more apt analogy, RollsRoyce. If the latter comparison seems absurd, one needs only to look beneath the Electra Glide's brilliant metallic paint and chrome to discover that it is a patiently developed piece of machinery that has been built to carry passengers comfortably, rapidly and effortlessly for many thousands of miles.

Admittedly, a great deal has happened in Milwaukee since we tested an FLH (Jan. `64). The outstanding change is, of course, that the bike has an electric starter and, thus, a new name. One of our first thoughts about the electric starter was its effect on the long-time H-D en thusiasts - the people who have been buying new Harley roadsters every couple of years since `way back. Would they think it frivolous or unsporting, since there has long been a mystique about the proper way to start a Harley? Well, apparently — in view of increased sales — the Harley enthusiast is a reasonable and progressive man and is not hide-bound to senseless traditions like many of his sporting brethren.

The entire electrical system in the FLH has undergone an overhauling to accommodate the starter, and the rest of the electrics have benefited in the process. The 12-volt, 53-amp-hour battery not only provides the power to quickly bring the large twin to life on cold mornings, but is more than ample for the big sealed-beam headlight, the bright taillight, the directional blinkers and the several indicator lights. There exists a somewhat amusing story concerning the starter motor. For the early Electra Glides, Harley-Davidson selected a starter that had long been employed on large displacement outboard boat engines. Alas, the unit had one strong failing; it was highly susceptible to water damage and corrosion! The current starter, manufactured by Homelite, doesn't experience this weakness and performs its task willingly. The Electra employs an automotive-type Bendix starter spring and pinion which engages a ring gear on the clutch shell.

CYCLE WORLD ROAD TEST

The big V-twin has a few refinements over its predecessors and a number of innovations not usually found in motorcycles. A major advance for '67 is intake port design. It's difficult to "eye-ball" a port and immediately know that it is right. But, if we are to apply a few known quantities such as port length, contour, and cross-sectional changes throughout the port length, and back this up with observations from gentlemen who devote their lives to making the Milwaukee monsters superfast, we can only conclude that H-D has hit a new high in design. There is almost an intuitive thing about the new ports. In a word, they appear to be optimum, and in light of the horsepower increase, however slight, this feeling gains credence because, other than the carburetor, this is the only powergaining change for the '67 FLH.

The new Tillotson diaphragm carburetor, introduced on Sportster models last year, has found its way to the Electra Glide this year. The carburetor offers a decided advantage in mid-range tuning, and, we are informed by a most-knowledgeable source, the rider-owner can easily learn from his local H-D mechanic the proper method for keeping the device "on the money." Previously, midrange alterations involved jet changes with attendant removal of the carburetor. Now, these changes can be made externally with the carburetor in place.

Harley has retained their hydraulic lifters, and for good reason, considering that the very tall barrels have an expansion/contraction range of about .042. The Electra retains the external upper-end oil lines that appeared first in 1964, and these are most welcome in that they eliminate the oil seepage at the cylinder bases, produced by the widely differing expansion coefficients of the alloy crankcases and the cast iron barrels. The barrels, by the way, are aged in typical Harley practice. However, it has been some years since they abandoned the stored-out-ofdoors method for something a bit more scientific — although the old method seemed to be pretty effective.

Those very important components inside the barrels — the pistons — still appear to be one of Harley's strong points. Harley is proud of their pistons, and well they should be. They cast their pistons in permanent molds and grind them to size. One of the major "secrets" in their approach is the internal cast-in-place steel expander. This expander, set perpendicular to the wrist pin axis, prevents the thin "sides" of the pistons from moving inward when the meatier pin-boss sides expand. And while pin-boss expansion cannot be prevented, Harley does compensate for it by grinding a .032 cam on the pistons at the thinner axis. If for nothing else, we present this engineering dissertation to justify mentioning that Harley sets up production FL engines with piston clearance of .001 to .0015! The "slop" is for the benefit of the rider who hasn't the time to break in his machine.

For 1967, Harley-Davidson has returned to a castiron oil ring after discovering that their three-piece — plus expander — oil ring was outlasting the rest of the friction surfaces in the engine. Their primary consideration was not really the life of the ring, but instead that it required a longer break-in period and capped it off by outlasting everything else!

We've mentioned that the Electra Glide has a number of innovations uncommon to motorcycles. Well, we would like to tell a little tale on the automotive industry. For several years H-D has been building interesting valve guides. They start with a rough guide, before heat treating, thread it and then grind it to size, leaving an everso-slight spiral in the ID. Then, they heat-treat the devil out of it — to a value called "jet turbine steel." The stay-behind spiral encourages carbon buildup inside the guide which acts as a lubricant. The result, of course, is self-evident. Detroit has recently caught on to this concept and, if you read the automotive slicks, you will no doubt be hearing a great deal about it.

Another FL modification we're happy to see, although not new this year, is the primary chain lubrication system, which not only reduces chain adjustment problems, but does away with the oil dripping characteristics of earlier models. In the present system, the primary chain is given generous spurts of oil from the transmission, and the oil, after passing through three filters, is returned to the transmission.

The lower end on the Electra Glide is characteristically stout. Generous tapers on the crankshaft facilitate flywheel alignment during assembly, both initially and during rebuild. Harley-Davidson, who by the way build very fine bearings, defer to an outside source — Timken — to provide a double roller bearing for the crankshaft output side. This unit is sturdy enough to see duty in a large-displacement automobile engine and is the only non-Harley bearing in the motorcycle.

The frame for the Electra Glide is little changed from previous FL models. The center section has been opened up a might to accommodate the starter and larger battery, but that's about all that has been done to it. The rear spring/shock units are mounted much too far forward. The reasons for this are that Harley's civilian buyers need room for their panniers, and law enforcement agencies — which account for a significant number of Harley's sales units — require space for their emergency equipment. It's a shame, really, that Harley doesn't tell its customers that they are going to have to bend a little, because the hefty rear suspension units are at a mechanical disadvantage set so close to the swing arm pivot. Unhappily, the existing concession gives the bike some unpleasant handling characteristics that manifest themselves in the form of protracted up-and-down oscillations in turns and "hobby-horsing" on pronounced ripples. These unpleasant habits are made up for in part by the splendid manner with which it copes with wheel-grabbing expansion joints and sharp-edged irregularities such as railroad tracks. The motorcycle is totally unmindful of these annoyances and passes over them as though they didn't exist.

Stuffing the Electra Glide into a turn, particularly for the rider accustomed to more nimble machinery, is an experience that is at first unsettling, followed by a feeling of revelation, and terminating in total acceptance of the idea that the bike is fully capable of negotiating bends at moderate speeds no matter what it feels like it is doing. The FLH has a "don't push me; let me do it my way" attitude in which even the uninitiated soon place complete trust.

In one very important area — brakes — the Electra Glide is terrible. The hydraulic rear brake is not bad, by itself. But it shouldn't have to work by itself, which in practice it does. The mechanical front brake has been around since 1949 and is most certainly due for retirement. As a hill-holder it is fine, but as a front brake for a heavy, fast motorcycle, it's laughable. Fortunately, the FLH prefers to travel in a straight line; even the most violent stomp on the rear brake pedal, sufficient to produce tire howl, will not prevent the machine from making erect, controllable stops. Our major gripe is that the stopping distance is not nearly as short as it might be if the rear brake were given more help from the front unit.

The paint and plating on the Electra Glide are good, and we particularly like the satin finish on the integral fork shroud-headlight nacelle. Despite the "automotive" look of the castings, forgings and welds, fitting and assembly are quite good.

In its field — high-speed, long-distance touring — the Electra Glide is without equal. The Harley-Davidson 74 V-twin is one of the finest motorcycle engines ever built — not because it is revolutionary or unusual, but because it is the product of years of thoughtful, careful, conscientious development.

HARLEY-DAVIDSON ELECTRA GLIDE

SPECIFICATIONS

$2100

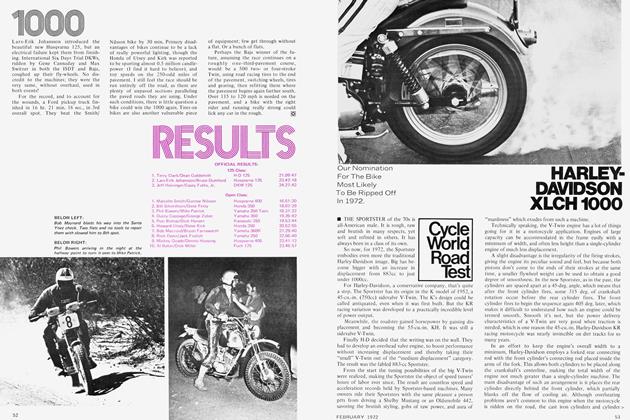

PERFORMANCE