INSIDE THE OUTSIDER

Technical Analysis of the Shell/Shultz Royal Enfield Flat Tracker

GORDON H. JENNINGS

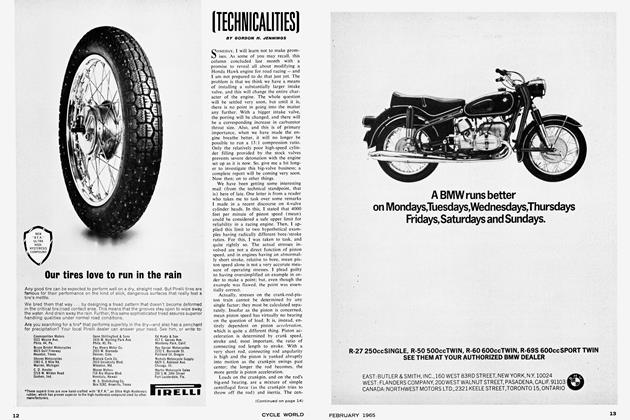

LURKING AROUND the Ascot half-mile flat track, in Los Angeles, YOU will find a collection of BSA-based racing specials that have been developed just for the track in question and are practically unbeatable there. We say "practically unbeatable" because these much-modified BSA Gold Star singles do get their comeuppance from time to time. The latest to give the "rotorooters" difficulties is a real outsider, the 500cc single-cylinder Royal Enfield tuned by Shell Thuet. who owns Shell Motors, and ridden by Elliott Schultz.

Schultz and the Enfieid single have been a bad news combination for the I3SA con tingent having at one point in the 1964 season won 31 of 39 races entered~ and stringing together 9 straight main event wins Sammy Tanner captured the Ascot championship but Schultz was out for a month due to injuries received in a late season spill This is not to say that Schultz and the Enfield were unbeat.bie; Tanner

was able to do the trick, and so was Blackie Bruce on occasion. However, the Schultz/Enfield combination was consistently the one to beat, and the myth of BSA-single invincibility was fairly well laid to rest in the process.

In light of Schultz's phenomenal 1964 record, one might think that the Enfield he was riding would be a real secret weapon. incorporating all manner of exotic parts. Surprisingly, that is not the case. Shell Thuet gave us a conducted tour through the innards of his “secret weapon.” and there is just simply nothing exotic about it. The only thing that makes it so remarkable at all is that it is so very much like a standard Enfield, with a bare minimum of special parts.

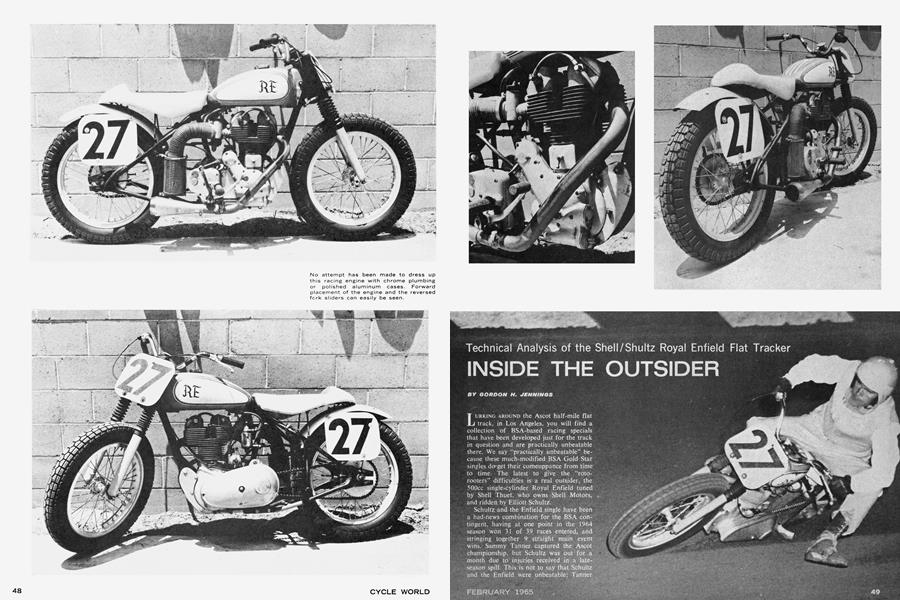

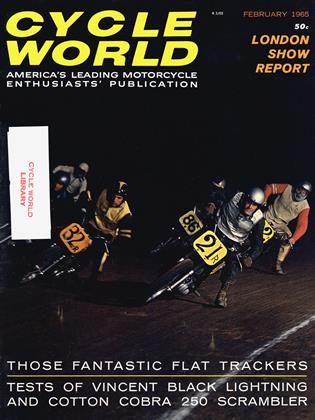

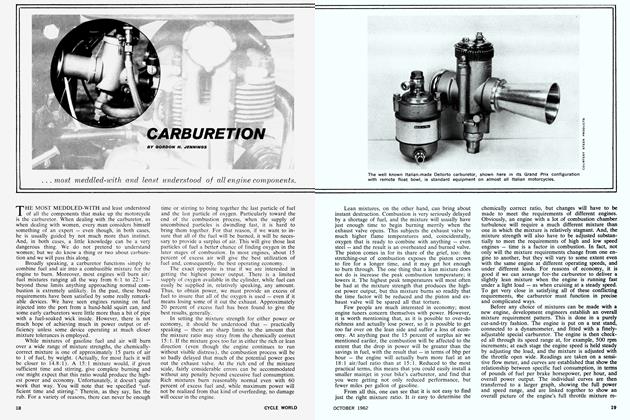

Erom the outside, the Enfield's engine appears to be entirely stock but for an Amal GP carburetor (IV2" throat) and a megaphone exhaust system. There is not even the usual oversize stub welded into the cylinder head; the carburetor bolts to the head in standard fashion. Inside the head, there has. of course, been some work done. The intake port has been opened to match the IV2" carburetor throat at its outer end. and at the other it rolls out into the seat for a 1 31/32" intake valve. Both the intake and exhaust valves are whittled from “blanks.'’ There has been no re-shaping of the combustion chamber, and while the intake port is somewhat larger in diameter than stock, no attempt has been made to increase the swirl-inducing offset, or the angle of downdraft.

Some changes have been made in the valve-actuating train. Harman and Collins cams are used, in conjunction with Webco flat-tappet type followers and racing valve springs. The stock Enfield rockers are rather heavy, so a special lighter set was made up from heavy-wall tubing and plate.

One of the real shockers you will find inside the Thuet-Enfield engine is a re-

worked stock Enfield piston. These pistons are, in the off-the-shelf form, very unimpressive-looking sand castings, and while they gain considerably in efficiency through Thuet's modifications, they are still not exactly precision racing parts. Thuet welds additional aluminum on the piston’s crown, to push the engine’s compression ratio up to 10.5:1, and then thins the piston skirt with a rotary file for lightness. The underside of the piston crown is dimpled with a drill to remove yet more material, and the “finished” part is somewhat lighter than the stock part. Even so, it remains a relatively heavy piston, and it is decidedly unlovely. But, however “stone-age” the piston may look, there can be no disputing that it does the job, and performance, not appearance, is the standard by which all such things must be judged.

Another part that will give you something to think about is the connecting rod. The standard rod is not up to the loads imposed by the up-to-8000 rpm racing service the engine gets, so Thuet has substituted a forged aluminum connecting rod made by Howard for the Chevrolet V-8. Thuet buys these rods in the as-forged condition, before they are cut and machined for an automotive-type detachable rod cap. The rod forging is machined to give the proper distance between the “bigend” and wristpin holes, and a steel sleeve is pressed into the crankpin end of the rod. The steel sleeve is necessary because Thuet is using the stock Enfield rod bearing, which is a thick-wall steel ring with a thin coating of babbitt inside and out. This is a full-floating bearing, inserted in the wide annular gap between the rod and the crankpin, with a series of radial holes to feed oil across from the crankpin side out to the side of the bearing immediately adjacent to the rod. It would be easy for Thuet to make the switch to a roller bearing. but the standard Enfield setup has proved to be completely reliable — and that is more than can be said of other engines that use roller bearings in the rod’s big-end.

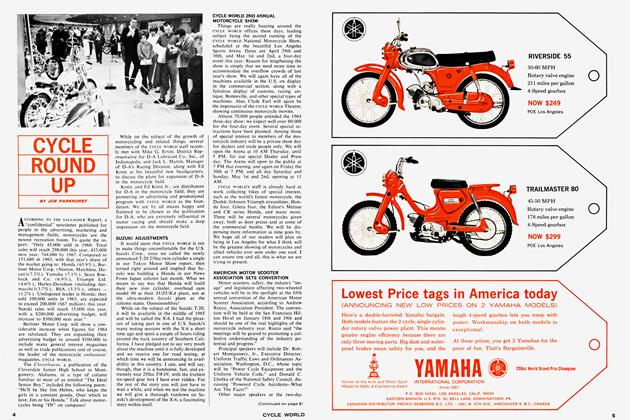

This engine is set into a frame left over from the days when Indian sold the Enfield under their name in this country. The frame was made by Indian, for racing, and it has the typical flat-tracker's solid rear section. Modifications have been made to permit moving the engine well forward in the frame, as this balances the machine better for conditions at Ascot. The front fork legs have been reversed so that the axle mounting lugs are behind the fork sliders, rather than in front, and this relatively simple expedient has increased front wheel trail. Also, because it pulls the front wheel back about 21/2", it has the effect of placing even more weight up forward.

A set of aluminum-alloy engine plates are used, and that saves a little weight, but the fact that Thuet is content to employ a steel fuel tank indicates that he is not overly concerned with building a superlight motorcycle. Instead, he concentrates on a wide power range, reliability and good handling, and he has found a combination of these qualities that is very impressive indeed.