CYLINDERS:

GORDON H.JENNINGS

OLD WIVES’ TALES abound in any field of interest, and motorcycling is no exception. Much of the information that the average enthusiast hears, and accepts without question is likely to prove, on close examination, to be only half true, or to have no basis in fact what-soever. This is not entirely the fault of the individual; the motorcycle is, after all, a somewhat more complicated mechanism than is immediately apparent, and it is all too easy to acquire a considerable body of misinformation on the subject. It is the function of CYCLE WORLD magazine generally, and this article particularly, to help set things straight.

Perhaps the most cherished of all beliefs is that low speed torque is the exclusive property of the long-stroke, single-cylinder engine, and that a short-stroke twin is suited only for fast operation and maximum power. The truth is that low speed torque is a characteristic of longstroke singles only because they cannot be run fast enough to make any kind of a showing as power producers, and that if any engine designer cared to do so, he could whip up a short-stroke twin that would have exactly the same low-speed torque characteristics as the single. There are, however, compelling reasons for the existing order, which we will cover in due course.

Essential to the discussion at hand is a real understanding of the nature of torque and power, and although the two are much discussed, many do not quite understand what it is all about. Torque, taking first things first, is merely a twisting force, usually given in pounds/feet. Take a shaft with a lever-arm extending out horizontally at one end, and then hang a one-pound weight on the arm at a point twelve inches from the shaft centerline and you will have produced a one-foot/pound torque on the shaft. The shaft does not have to move; the torque exists independent of motion.

Horsepower is something else again; it is work, and the unit was established, arbitrarily, by James Watt, as one pound, raised 33,000 feet in one minute. The unit can also consist of a 33,000-pound weight being raised a single foot in the same unit of time, or it can be a pound, raised a foot, in 1/33,000-minute.

Both power and torque in the piston-type, internal combustion engine, have their source in the expansion of the gases (nitrogen, and the other components of air) heated in the combustion process. Horsepower will depend on the quantity of gases involved, per unit of time, and the output can be increased by either increasing the total piston displacement, which will pump a greater volume through in each stroke, or by simply making more strokes in the same time. From this, we may see that, assuming we are able to maintain a reasonable level of volumetric efficiency, power output will be independent of displacement. There is no firm and fast upper limit to the amount of power that can be wrung from an engine of any given piston displacement.

Torque, on the other hand, may be described as being entirely dependent on displacement, and independent of engine speed. Torque is produced by gas-pressure forcing the piston down, via the connecting-rod, against the crankpin. At any fixed displacement level, we may shorten the stroke and enlarge the bore, or lengthen the stroke and reduce the size of the bore, and the torque produced (assuming that the gas-pressure is the same) will not be changed. The increase in crankpin leverage provided by lengthening the stroke will always be offset by the loss of piston area (where the torque-producing gas-pressure is applied) and the loss of leverage incurred in shortening the stroke will be offset by the gain in piston area. Further, at any given total piston displacement, the division of displacement among individual cylinders will have no effect; all other things being equal, the single will pro-

duce the same torque as the twin, or a four, or even an eight, or indeed any number of cylinders. It is true that a 500cc single would have a peak torque twice as high as a twin of the same capacity, but the twin’s torque pulses would occur twice as often, with the result that the average torque reading would be the same for both engines. And, this also extends to even greater divisions of displacement.

It must be apparent, at this point, that the theory we have been discussing bears little relationship to the existing situation. As a practical fact, singles do have superior low-speed torque and twins generally give more power. The answer lies in one thing: cost. To explain this, let us assume that we are going to design and construct three motorcycle engines: the first is to be used for slogging along over rough terrain; the second is to be for highway touring; the third for racing.

In the first example, a trials engine, it will be obvious that good low-speed torque and general tractability are the most important considerations. Thus, we will have no need of an engine that will turn 8000-10,000 rpm; the range from 500-4000 rpm is much more important. Now then, experience tells us that without using expensive alloys, or overhead camshafts, or anything but the most simple and inexpensive of materials or methods, we can construct a single-cylinder engine that will perform reliably within that stated speed range. Obviously then, the single-cylinder configuration is the one to use: a twin

would do the same job, but only at some added expense in mechanical complication and manufacturing cost.

For our touring engine, the choice is somewhat less clearly defined. In the end, the number of cylinders will be determined by the riders for whom the engine is intended. If the engine is aimed at the performance-conscious segment of the enthusiast market, the engine’s total displacement will have to be fairly large, around the %to 1-liter size (750cc to lOOOcc), and there are not many riders who would care to live with a lOOOcc single. At least two cylinders are, therefore, indicated.

For the cost-conscious rider, who is willing to accept certain disadvantages in power-output and, to some extent, ease of starting, there is justification for the use of a single cylinder layout. Particularly, under the 350cc level, the single can be made to turn fast enough to develop quite a lot of power (relative to displacement). In the small single, the stroke can be made short enough

SINGLE, TWIN OR MULTI?

The effects of cylinder dimensions on power and torque.

to allow a very high operating speed without the bore becoming so large that the combustion chamber gets to be an inconvenient size. (More on this later.)

For out-and-out racing engines, there is every reason to assume that more, and not fewer, cylinders will give more power output — and that is all that should have to interest the designer. In point of fact, though, even in so lofty a thing as racing, cost is still very much with us and it is that factor alone, once again, that determines the final shape of the engine. And, we must admit, it is possible to create an engine that is so complicated that it becomes too large, and heavy, to entirely justify its complexity — and it may even prove to be impossible to keep in racing tune throughout a busy season. That is, when all is said and done, the reason for the long-term successes of England’s famous singles: they have always been inferior, in terms of pure power output, to the twins and fours from the Continent, but they are much easier to maintain and have always been somewhat more likely to come to the line with everything necessary having been done. A four, no matter what its theoretical merits, is no match for a good single when running only on three cylinders.

After selecting the number of cylinders, or perhaps during the process of selection, it will be necessary to give thought to basic cylinder dimensions. Any given unit of piston displacement can be produced by an almost infinite range of bore and stroke dimensions. It is, as every-

one knows, possible to have — even if we restrict ourselves to the “normal” range — long-stroke and short stroke versions of, for example, a 500cc single. There is something to be said for both types, both long and short stroke, but the historical trend, and the balance of the favorable factors, lean heavily toward the short-stroke configuration.

One of the most compelling reasons for using the shortest possible stroke is that, in the end, it will result in more power being produced — and without any loss of torque. For a variety of reasons, many of them obscure and all of them too involved to cover here, maximum power will be obtained when the mean velocity of airflow through the intake port reaches about 260 feet per second; this figure having been determined by studies of engines of widely varied sizes and layout. And, the airflow velocity will be closely tied to piston speed, the actual value being a function of piston speed, and the

ratio between piston area and the area of the intake port (always assuming that the valve head is large enough not to block the flow). And again, to go yet further, the mean piston speed will depend on stroke and crank speed, increasing with each. Thus, discounting “freak” valves and porting, the power peak will depend on the stroke, and a short stroke will give peak power at a high rate of revolution, which virtually insures that great quantities of fuel and air will be pumped through the engine, per unit of time, and maximum power will be obtained.

A side effect of this will be that the torque peak will also be elevated. Maximum torque occurs when the flow through the intake port is around 180 feet per second, and in the short-stroke engine (with a “normal” valve and porting layout) this velocity will only be reached at a relatively high crankshaft speed. Of course, the fact that it occurs at a higher speed in no way changes the actual torque output.

Increased crank speeds do, unfortunately, have their effect on the power output. Internal friction tends to rob ever increasing amounts of the power obtained by turning the engine faster, and the extreme valve timings necessary to provide time for the valves to open and close at high crank speeds has a depressing effect on the low speed power output. The end result is that a short-stroke engine with valves, valve-timing and porting that allow it to take full advantage of the high-speed output characteristics we have been discussing will have no power, or torque (for

the reasons outlined in the preceding paragraph) until it is running quite fast.

Strictly speaking, there is nothing to prevent the engineer from designing a short-stroke engine that has good low-speed torque. All he has to do is make the valves and ports of the proper size to give the torque and power peakproducing flow velocities at a lower piston speed. However, there are other factors that will, usually, prompt him to lengthen the stroke. At any set level of torque output, the long stroke will give a lower connecting-rod and connecting-rod bearing loading, and the smaller bore that is the partner of the long stroke gives a smaller, lighter and more easily-cooled piston. Also, the small bore provides a compact combustion chamber, in which combustion irregularities such as detonation, are less likely to occur.

This brings us to yet another aspect of the great bore/stroke-ratio question : the absolute size of bore that will be thermally and mechanically convenient. With regard to

the former, we can only say that it has proven practical, if not absolutely desirable, to have cylinder bores up to 4-inches in diameter, using ordinary gasoline fuels and compression ratios up to 11:1. On the face of it then, it would seem possible to build an engine of, say, 15-cubic inch capacity with a 4-inch bore and a stroke of only 1.2inches, allowing a crank speed of 17,500 rpm before the mean piston speed reached 3500 feet per minute, a speed that is generally regarded as a conservative, safe maximum. Obviously, there are flaws in this scheme, or someone, like Honda, would elect to do this instead of building those expensive and complicated fours.

Although there are several things that would prevent an engine having such an extreme bore/stroke ratio from working, the most serious problem is getting an adequate compression ratio. With such a large bore and tiny stroke, even the most careful attention to achieving minimum clearance volume would still not produce a very high compression ratio. Indeed, if we make allowances for valve-head cutouts in the piston, it seems unlikely that the ratio could be made much higher than, perhaps, 5:1.

Added to this problem is that of bearing loads. The loadings at the torque peak would be extremely high, and although both connecting-rod and bearings could be made strong enough, they would become really too large for convenience. This is particularly true of the bearings, which, if large enough to take the load at the torque peak, would also constitute a serious friction source at all speeds.

Finally, with such a large bore, it is most unlikely that a pair of valves, of appropriate size, could be pursuaded to follow the cams at the 17,500 rpm engine speed we are discussing. Smaller valves would, of course, but then smaller valves would not allow the engine to breathe at 17,500 rpm. A partial answer is the use of four or more valves, which introduce even more convolutions into the shape of the combustion chamber and make the compression ratio drop even further. In the end, it becomes obvious that there are limitations to the bore/stroke ratio. Experience indicates that an equal bore and stroke is a good starting point, with a longer stroke if the engine is to be used for slow running and a shorter stroke if it is power we have in mind. Incidentally, we might mention that a “square” engine, one having an equal bore and stroke, has bearing loadings well balanced between those produced by gas-pressure (at the torque peak) and those created by pure inertia. In the very short-stroke engine, the highest bearing loads will be produced by gas pressure; in the long-stroke engine, inertia forces will produce the highest loading. This is, of course, true only through the medium speed range; inertia will, if the engine is turned fast enough, always account for the heaviest loads.

Apart from all other considerations, the bore/stroke ratio has a marked effect on the breathing characteristics of an engine. In the four-stroke engine, volumetric efficiency will always be produced by the largest possible bore, which provides room for the largest possible valves. But, as we have tried to make clear, unless the absolute maximum in power is desired — even at the expense of low speed tractability — it is not necessary to go overboard in this direction.

Exactly the opposite is true of the two-stroke. The greatest port area and best breathing is obtained by making the stroke greater than the bore. We have prepared a purely hypothetical example involving two 15-inch engines, one having a 2.50-inch bore and 3.08-inch stroke; the other a 3.00-inch bore and 2.14-inch stroke. Both engines have the same port timing: the exhaust port height is 35percent of the stroke; the transfer ports have a 25-percent height; the exhaust port and transfer port widths have been assigned straight percentages of the bore sizes. As it

works out, the exhaust port in the long-stroke engine has an area 19.7-percent better than its short-stroke counterpart, and the transfer ports in the long-stroke example show a 16.85-percent advantage. Thus, taken strictly on the basis of getting gases in and out of the cylinder, the long-stroke design has a marked superiority. However, the crankcase volume tends to be inconveniently high in the long-stroke engine, and the pumping pressure may* at high speeds, be too low to make proper use of the increased port area. Also, the piston speed places limitations on its safe running speed. If we accept, for convenience, the arbitrary level of 3500 feet per minute piston speed, we find that the long-stroke example is limited to just over 6800 rpm. The short-stroke engine, at the same piston speed, would be turning over 9800 rpm. With proper attention to other areas, the short-stroke engine is sometimes able to overcome its porting deficiencies by its ability to run at higher crankspeeds. In the examples given here, the short-stroke engine has less than a 20-percent deficiency in port area, and a 50-percent advantage in safe running speed. Here, again, the choice depends a great deal on the use for which the engine is intended.

Thermal efficiency, a subject we hesitate to get into very deeply, in the final analysis becomes a matter of the ratio of surface area to volume in the combustion chamber. Therefore, the long-stroke, single-cylinder engine (which has only one, small combustion chamber) has the highest efficiency and the short-stroke multi the lowest. This factor is, however, of secondary importance in racing engines, though — if ignored — it can be the cause of poor economy in a touring engine.

Mechanical efficiency is a consideration that also favors the single, but not necessarily the long-stroke variety. Most of an engine’s internal friction comes from piston drag, and the ratio of piston-skirt area to displacement is better in a single. And, too, valve-gear drag, etc., goes up sharply with increases in the number of cylinders.

It shoud be understood that both thermal and mechanical efficiency have their effect on power and torque, and that the ideal circumstances we used in our discourse on the nature of the effects of bore and stroke never really exist. Due to these effects, and the sundry influences of pulsation in the intake timing, the final power and torque characteristics can vary somewhat from that which theory predicts. But, the theory still holds true, and all of the things we have said about power and torque, relative to engine layout, are also true. The need for low speed torque may indicate to the designer that a long-stroke single is required, but it is because the nature of the task allows him the luxury of using an inherently simple, reliable and inexpensive engine configuration — not because the longstroke single has, by its nature, those properties he wants. In the end, competition will force the end of the single, as it cannot be made to produce the same power as the twin. The twin can easily have the single’s torque, and a lot more power as well, although in practice both would occur at a higher crank speed. Moreover, the twin will ultimately have to give way to the four, and the four to the six, until the piston-type engine is replaced by something else. Today, the single may occasionally, or even often, beat the twin in various kinds of racing, but when it does it will be because of some deficiency in the particular twin it ran against. In some applications, the old single is still a very good choice, of course, but that does not alter the fact that, in the end, the trend will continue toward more, and not fewer, cylinders, and that even when the single is used, the trend will be toward a shorter stroke and higher operating speeds, because in that way more power will be obtained and the torque will suffer little, if at all. •

View Full Issue

View Full Issue

More From This Issue

-

Cycle Round Up

January 1963 By Joseph C. Parkhurst -

The Service Department

January 1963 By Gordon H. Jennings -

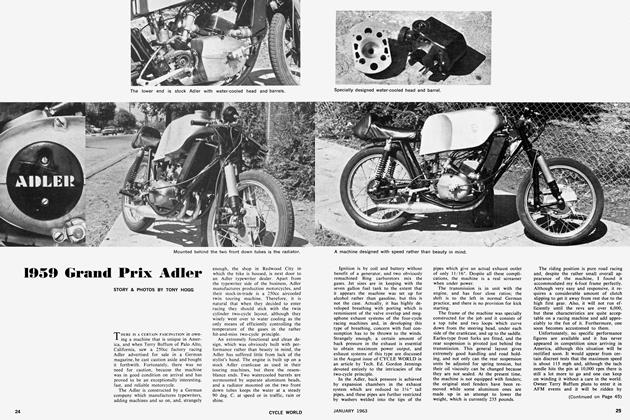

1959 Grand Prix Adler

January 1963 By Tony Hogg -

Sandy Lane Enduro

January 1963 By John Eddy -

A Cycle World Classic: 1914 Excelsior

January 1963 By Paul A. Bigsby -

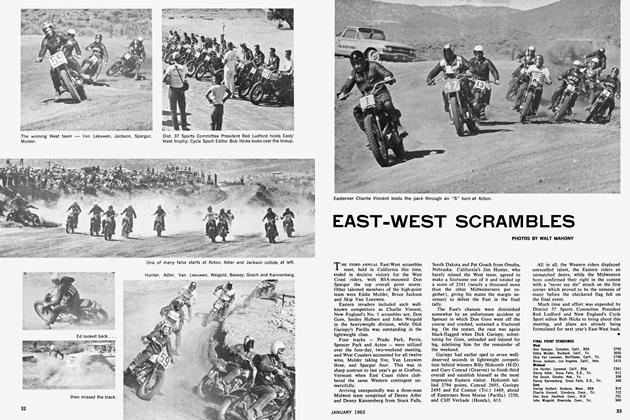

East-West Scrambles

January 1963