THE SERVICE DEPARTMENT

GORDON H. JENNINGS

DYNAMOMETERS

Could you help me to find plans on how to make a dynamometers? I have a Triumph dragster, and it would probably turn a much better time in the quarter if 1 had a “dyno” to tune it with.

ROBERT ACQUISTAPACE Hollister, Calif.

Yes, you are quite right, a dynometer would help you to get through the quartermile a little faster—or perhaps even a lot faster, depending on how good an “ear” you have for tuning. One thing is certain: no matter how sensitive a person is to the sound of power, he will never get as much from an engine as the man who is aided by a dynamometer. When the competition gets, tough, even a very small increase in power is hard to find—and without a dyno, you can go right by and never even know it was there.

Unfortunately, the commercially-produced dynamometers we have seen are not at all suited to the needs of the private speed-tuning artist. In the first place, they are dreadfully expensive — costing more than the average motorcycle—and secondly, they are extremely bulky and present overwhelming installation problems. Moreover, most of them are made to operate up into the 300-plus horsepower range and you simply don’t need all that they have to offer—especially at the price.

We have given this matter considerable thought and have come to some hopeful conclusions. At the onset, let us say that there is no reason whatsoever for having a dynamometer that gives direct readings in terms of brake horsepower. Such things are interesting to know, naturally, but they have no bearing whatsoever on experimental tuning. Such work requires only an instrument that will give accurate indications of a rise or drop in engine output.

Because there are no readily available and inexpensive dynamometers to be had, the thought arises that some kind of “home-grown” rig might be the answer. The most simple dyno is the old friction brake, in which the engine turned a brake drum and brake shoes were used to apply the load. The force being developed by the engine was indicated by a lever leading from the brake “backing-plate” to an

ordinary spring or balance-type scale. The backing-plate tends to turn with the drum when the brake shoes are in contact and this force was relayed to the scale, which read in pounds, by the lever we mentioned. This type of dyno works, more or less, but it has one great failing: the brake “fades” very soon. Consequently, only flash readings are possible.

Such a characteristic makes experimental work all but impossible, for one no sooner gets going than the dyno begins to fail. However, the scheme might work if a large disc brake were used and some provision made for adequate cooling of the mechanism. A water-spray, directed on the disc, would be a trifle messy unless surrounded by some sort of housing, but otherwise has much to recommend it.

There are other types of dynamometer: the ones used by most manufacturers are of the electrical type, in which the engine turns a generator. The load on this type of instrument is applied by varying the resistance of the line running across the poles of the generator, but for the actual reading, we get right back to the lever and scale. As the load is applied oh the generator, its field coils and outer casing (just like the shoes and backing plate on the friction-brake dyno) will tend to rotate with the armature. This torque is, once again, carried by a lever to a scale.

Hot-rod shops, when they have a dynamometer, most often have one of the water-brake type. In these, the engine is forced to pump water against a resistance —which can be varied— and the reaction torque usually ends up (you guessed it) acting through a lever against a scale.

Our objection against the electrical dynamometer is that it requires a very large generating unit and very heavy wiring to handle the kind of power developed by most motorcycles.

The water-brake type is more attractive from the standpoint of the backyard engineer, but it is open to criticism on the grounds of its sheer bulk. A big pump and a lot of water are required to handle 50 or 75 bhp.

There are possibilities in the use of automotive-type torque converters. If one of these could be rigged so that the output

shaft carried the torque arm to the scale and some means could be found for removing the heat generated by all that slippage from the converter casing, and to vary the loading, fairly accurate readings could be obtained.

The problem is, in every instance, exactly the same. First, we have to provide some form of resistance for the engine to work against, and it must be a variable resistance. Second, a lever is needed to transfer the torque created by the resistance to some accurate scale. Third, and finally, the enormous quantities of heat generated by whatever resistance is used must be removed as it is formed so that our instrument will: (a) give consistent

readings and (b) not burn itself to a cinder in use.

FIE, AND FOR SHAME

I enjoy your magazine, but the article you came out with in the January issue on the Triumph Bonneville does not seem right to my group or myself.

I own two I960 Bonnevilles, one of which I have been racing at the drap strip for some time. When it was stock it never turned an E.T. higher than 14.21 and in the low 90s for speed.

Also, the author seems to have made a little mistake in the specifications in that the cubic inch displacement of the engine is 40 rather than 36.5.

DENNIS CANCELLARE Las Vegas, Nev.

In the case of the displacement, you are almost right and we were definitely wrong. As a matter of fact, the correct figure is 39.5, and we don’t know how the mistake was made. Perhaps the dozen or so cuts with a riding-crop administered to the Tech. Ed. by the Editor will prevent such errors in the future.

As for the performance, we don’t manufacture the data, we just report it. It may be that your particular Triumph is very fast, and those of all your group as well. However, in the case of the machine we had for1 test, which we thought was terrific, the times we gave are quite valid. As we said in the test report, a more talented rider might have gotten slightly better times than we did—but not by too much. For our particular Triumph, on that day, on our test strip and under the prevailing conditions, the performance we got was just about all that there was. Even so, we are delighted to hear that other examples of the Bonneville are faster. RAM TUNING

(Continued on Page 43)

SERVICE DEPT, continued

ƒ have a question on ram tuning. On the end of my carburetor there is a tube that connects it to the air filter. Should this be measured in calculating the tuning distance? My cycle is a Honda CA-95.

Also, will the shape of the muffler affect the rebound pulses?

For the Service Department: inside the frame on the 125 and 150cc Hondas there is a solenoid. Make sure it has two anchor bolts if the cycle is ridden in the dirt. Otherwise, damage will result to the air cleaner. If it has only one bolt, it can be made more secure by using a piece of plumber’s tape.

GORDON B. THOMPSON Redondo Beach, Calif.

Thank you for the service tip. We are sure that Honda owners will appreciate it.

Unfortunately, the mere existence of an air cleaner and a muffler on your bike make it somewhat unlikely that the ram tuning effect will exist at all. In both cases, there is a pronounced damping effect and this stops the wave formation almost as soon as it begins. If the air cleaner was very large, and incorporated some sort of air chamber, the inlet - side ram effect would proceed unimpeded. In such a case, the pipe connecting the carburetor and the air cleaner would have to be included in any calculations.

On the exhaust side, there is almost no hope of getting any really useful ram effect when a muffler is used. The very elements in the muffler that dampen exhaust noise also squelch the wave formations that give the ram effect. If space considerations would permit, you could use a large expansion chamber behind a megaphone, and then lead the exhaust gases out an oversize muffler. That scheme would preserve the pressure pulses virtually intact and allow the use of the ram tuning technique. •

View Full Issue

View Full Issue

More From This Issue

-

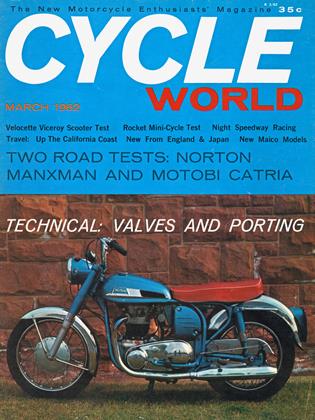

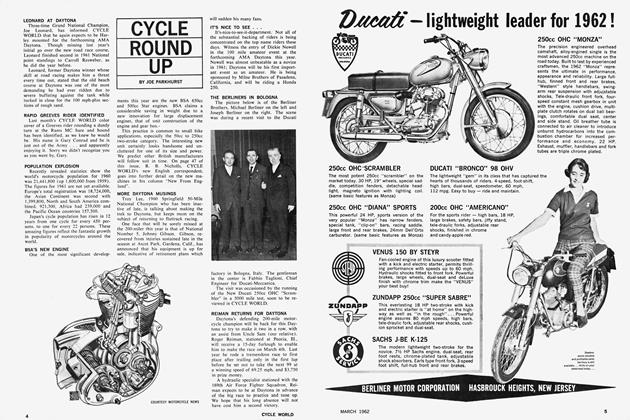

Cycle Round Up

MARCH 1962 By Joe Parkhurst -

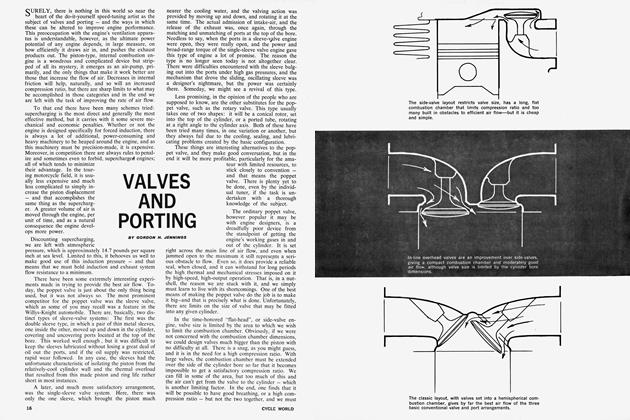

Technical

TechnicalValves And Porting

MARCH 1962 By Gordon H. Jennings -

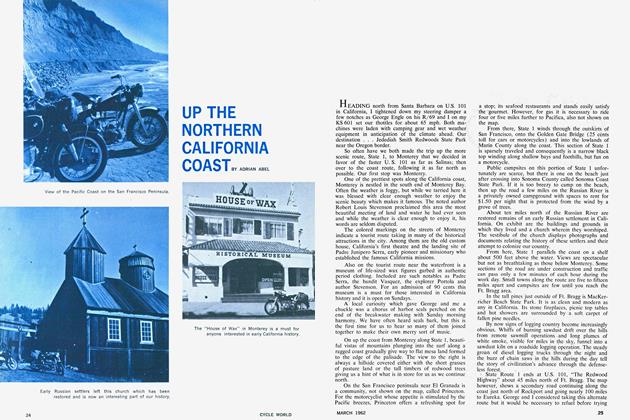

Travel

TravelUp the Northern California Coast

MARCH 1962 By Adrian Abel -

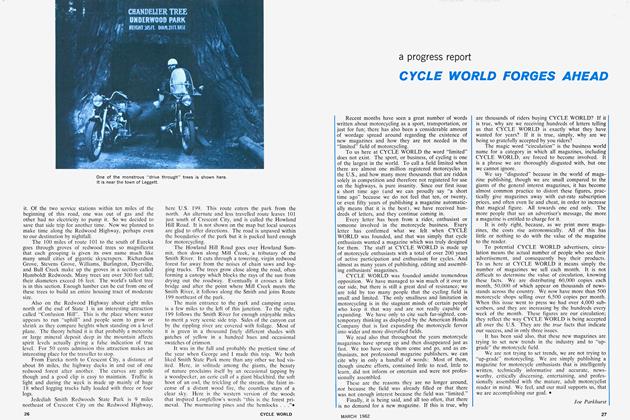

A Progress Report

A Progress ReportCycle World Forges Ahead

MARCH 1962 By Joe Parkhurst -

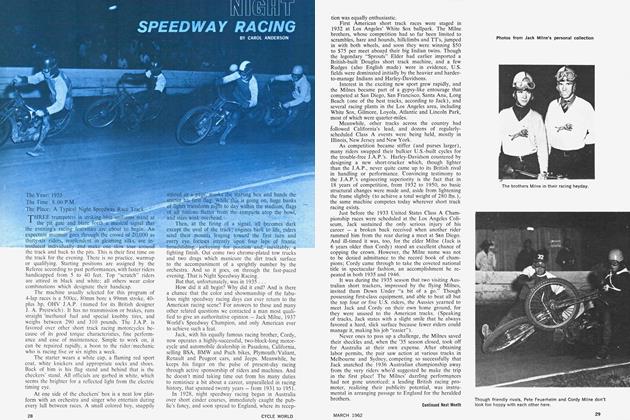

Night Speedway Racing

MARCH 1962 By Carol Anderson -

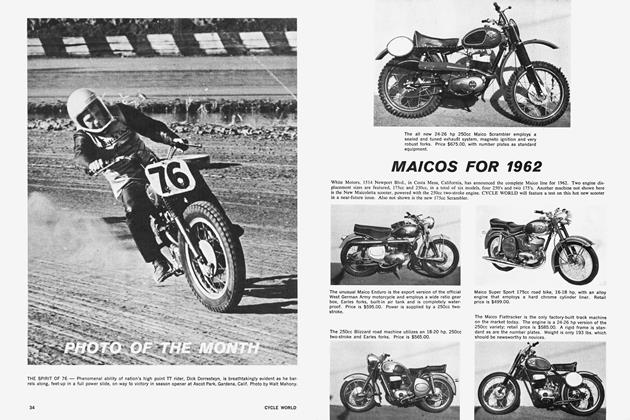

Photo of the Month

MARCH 1962 By Walt Mahony