ENGINE BALANCE

An anaylsis of the problems of balance in cylinder layouts, and an unwieldy solution.

GORDON H. JENNINGS

THE RECIPROCATING-TYPE, internal combustion engine has a great many fundamental disadvantages. It has a total lack of zero-speed torque, and must be cranked up into its operating range before it will run at all, and it has an unfortunate tendency toward self-incineration. However, the most bothersome of all its deficiencies is the mass of unbalanced forces that are present in the movements of its basic mechanism: the piston, connecting-rod and crankpin.

The piston, of course, is the most outstanding contributor to the problem; with each half-turn of the crankshaft it is taken from rest and accelerated up to (in some instances) 800 miles per hour, and then braked to a halt again. This occurs twice each revolution — or 16,000 times per minute in an engine running at 8000 rpm — and that kind of acceleration creates some very high-magnitude reaction forces. Sustained, these could lift the engine, motorcycle, rider, and most of his friends several feet in the air, but the forces peak sharply and then fade away. Even so, they are of sufficient magnitude, for enough time, to move things around a good bit and must be compensated in some way.

The crankpin too presents a problem; but it is, fortunately, a problem that is more easily solved. We can, by placing a counterweight opposite the crankpin on the crankshaft, balance for any or all of the crankpin. If the counterweight has the same mass as the crankpin, and is placed with its center of gravity the same distance from the crankshaft centerline, then the crankshaft at least will be in balance.

That brings us to the connecting rod. Whereas the piston’s motions are purely linear, and the crankpin’s are rotary, the connecting rod is a mixture of both, with movements that range from linear at the wristpin to rotary at the big end — all other points on the rod covering what are roughly elliptical paths.

From all this one might be led to think that the motions of the crankshaft are the only ones that can be balanced completely, with the connecting rod offering hope of partial balance and the piston none at all. This is, to some extent, true, but if we are willing to exchange some of the balance of one, for the benefit of the other, then a reasonably satisfactory overall balance can be obtained — as most of us already know.

A rough sort of rotational balance can be achieved by using counterweights equal to the mass of the crankpin, plus the mass of the connecting rod’s lower end. To determine the weight of the latter, it is necessary to suspend the connecting rod in a horizontal position, with the wrist pin resting on knife-edge supports, and the bis end on a precision scale. The reading thus obtained will equal the weight of that part of the connecting rod that has a substantially rotary motion. To check the crankshaft for this balance, it is necessary to make up a ringshaped weight equal to the weight of the lower end of the connecting rod and then slip it over the crankpin. When working with a built-up crankshaft assembly — such as is used in most single cylinder motorcycle engines — the weight can be made in one piece. For a twin, or any engine having a solid shaft, the weight will have to be split.

Counterweighting for the rotating mass will bring the lower end of the system into perfect balance; but it leaves us with the piston entirely uncompensated. At this point we come up against the inconvenient fact that all of the piston’s unbalanced forces are in a vertical plane (assuming a hypothetical single vertical cylinder) and crankshaft counterweights act through a full, 360-degree circle. Therefore, if we were to add further counterweighting equal to the mass of the piston and upper end of the connecting rod, we would merely transfer the shaking from a vertical plane onto the horizontal. The counterweighting that cancelled the piston’s unbalanced vertical forces would have nothing to counteract their horizontal effects, and the engine would begin to shake from side to side at the same frequency, and amplitude, as it had been shaking up and down.

There is no easy way out of this dilemma; the only solution that is at all acceptable is to compromise. By balancing for part of the vertical shaking forces, we get an engine that shakes both up and down, and from side to side, to some extent, but the overall amplitude is reduced to an acceptable level.

No hard and fast rules exist for choosing the percentage of reciprocating weight to be balanced. Most often, between 60 and 65 percent give the best results, but the figure may be as low as 40 percent, or as high as 80 percent — depending on the engine, and the motorcycle in which it is mounted. In the end, only experimentation will provide the answers.

Determining the reciprocating weight is done in essentially the same manner as we outlined for the weight of the connecting rod’s lower end: put the big end on knife-edges with a mandrel through the big-end bore, and weigh the opposite end with the piston, rings, and wrist pin in place. Then, by making the dummy weight equal to the weight of the rotating mass (the connecting rod’s lower end) and 60 or 65 percent of the reciprocating mass (which we have just described) and installing the weight on the crankpin the crank assembly may be balanced. Of course, the balance obtained in this manner will only be an approximation of the optimum, but that is as near as anyone can get before starting the cut-and-try procedure.

During the actual balancing process, considerable care will have to be given to insure that the counterweighting is evenly disposed in each flywheel. With all of the counterweighting on one side of the crank, static balance will be achieved but dynamic balance will not. When working with a twin the problem becomes especially acute, as the crankshaft assembly lacks the symmetry needed for easy balancing. In fact, while it is perfectly feasible to undertake a do-it-yourself balancing job on a single, using carefully leveled knife-edges to check the balance, the twin should be left to the professional electronic-balancing shop.

No matter how fine a balance we attain for the primary shaking forces, there will still be some engine vibration due to secondary shaking. There is a reaction force, acting through the main bearings, that sets up a vertical shaking at twice engine speed. At top center, the secondary force is directed upward, which reinforces the primary force that is also directed upward at that point. With the crankpin out at 90 degrees, the force is reversed, pushing the engine down, and it reverses again to partially cancel the downward primary force at bottom center. After another 90 degrees it is again directed downward and then, when reaching top center once more, it tends to lift the engine. Because these secondary forces operate at twice crankshaft speed, it is impossible to cancel them with simple crankshaft counterweights. A few engines have been built with gear-driven counterweights, running at twice crankshaft speed, to eliminate this secondary shaking, but they are not of enough consequence, in motorcycle-size cylinders, to worry about.

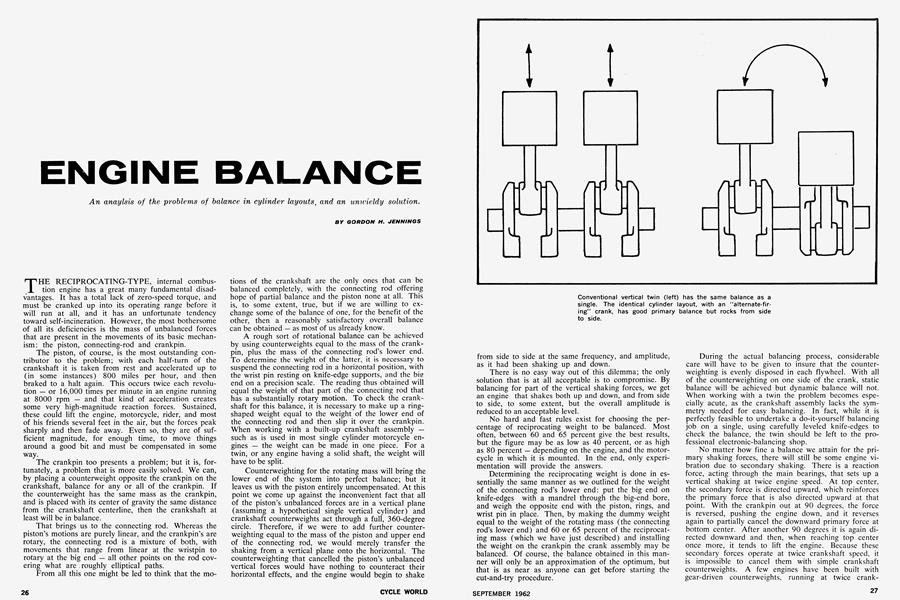

Insofar as the single-cylinder engine is concerned, even relatively vibrationless running is a thing that can only be had over a very narrow operating speed-range. Furthermore, the same is true of the conventional vertical twin. A great deal of nonsense has been spread about regárding the “smoothness” of the vertical twin, but in its balance it is exactly like a single — indeed, at any given displacement it will almost certainly be worse. Both pistons and connecting rods are moving together, and they are heavier than a single piston and rod (even making allowances for having the displacement divided between two smaller cylinders). They do, naturally, respond much more smoothly to a big handful of throttle, and generally start with less struggle.

There are a few varieties of twin that do have reasonably good balance. The twin with crankpins spaced at 180 degrees (like two-stroke twins and some of the Honda four-stroke twins) have primary forces that are intercancelling, but the cylinders are not on the same centefline and the offset between cylinders means that there is an offset in the opposing forces and this tends to rock the engine to the side. Even in an opposed twin, like the BMW, there is some offset between cylinder centerlines and the rocking effect will be present. Of course, the amplitude of the rocking will depend on the amount of offset between cylinders. If the engine is balanced only for the rotating mass, the rocking will be entirely in a vertical plane; with a 100-percent balance of the reciprocating mass the rocking will be horizontal, and here again the reciprocating balance may be provided in reduced percentages to split the vibration into vertical and horizontal components. The type of balance that will give the best results, in terms of overall smoothness, will depend to a great extent on the engine installation.

The V-twin offers some interesting possibilities for balanced running. The 90-degree twin, with 100-percent of the reciprocating weight balanced, has a perfect primary balance but a rather strong secondary vibration. It would, even so, be very attractive, except that it makes a bulky package, and gives extremely uneven firing intervals. Usually, a V-twin will have an included angle of about 50-degrees, which gives an overall balance that falls halfway between the badly balanced single and the “perfect” 90-degree twin. And, the 50-degree twin has much more even firing.

There is, oddly enough, a way of getting perfect balance with a twin — if we are willing to pay a fairly heavy price in mechanical complexity. One method is to use geared crankshafts in a vertical-twin configuration that is, in fact, a pair of singles running side by side. By gearing the cranks so that they rotate in opposite directions, we can balance for 100-percent of the reciproeating weight and, as the counterweights are working in opposite directions in the horizontal plane, there is a perfect primary balance. The secondary forces are still there, but with another pair of gears driving counterweights at twice crank speed, these secondaries can be eliminated as well.

A less complicated means of achieving the same end is with an opposed twin, using a three-throw crankshaft. This involves three connecting rods: the one in the center linking the center crankpin with one piston; the other two are on the end crankpins (these are spaced 180 degrees from the center crankpin) and both lead to the remaining piston. The purpose of this elaborate arrangement is to bring both cylinders onto the same centerline, and thus avoid the rocking couple we mentioned previously. As in all opposed engines, the secondary forces are mutually cancelling and this engine would have perfect balance. The reason we do not see this done is simply that the more conventional opposed twin, while not absolutely perfect, has so little uncancelled vibration that the possible improvement is not worth the struggle.

Going to more cylinders is, in the end, the most satisfactory means of improving balance. In two-strokes, the in-line three-cylinder configuration, with crankpins spaced at 120 degrees, gives good balance with nice, even firing intervals and a smooth flow of power. For four-stroke engines, the in-line four is a very good lay-

out, as all of the primary forces are in balance and except in very large fours, the secondary component is not large enough to be bothersome.

Fours can also be made in V-configuration, but for the motorcycle, which is usually air-cooled, the back cylinders pose some problems. However, the balance can be very good and perhaps we shall some day see some of these.

The “square” four, like the famous Ariel, has two geared crankshafts and a balance that is the same as the in-line four. Although the Ariel square-four was a success, in most respects, it really cannot be said that the layout has much to offer beyond being compact. And, the rear cylinders do get warm if air-cooling is used.

As we have shown, balanced running with the pistontype engine is not easily, or cheaply, obtained. Moreover, the best opportunity for getting it is in the use of several cylinders, and that is both expensive and bulky — neither of which can be afforded in motorcycle design. And, too, the level of balance with existing singles and twins is good enough so that there is no compelling reason for making a change. We may expect that this situation will prevail for some time. In the end, though, and the day could come sooner than now seems likely, those in-line fours that dominate racing are going to reach the production line and the main problems of balance will be materially reduced, if not eliminated. •

View Full Issue

View Full Issue

More From This Issue

-

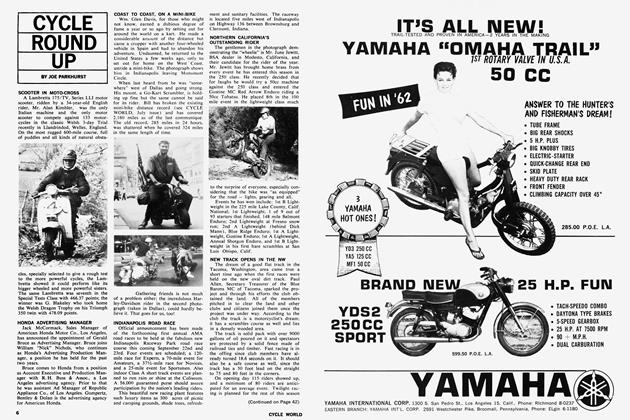

Cycle Round Up

SEPTEMBER 1962 By Joe Parkhurst -

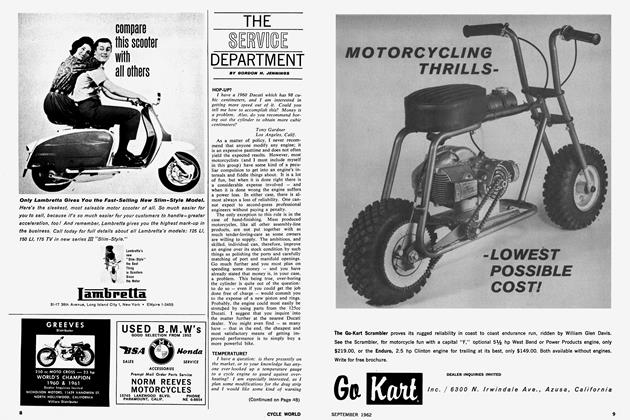

The Service Department

SEPTEMBER 1962 By Gordon H. Jennings -

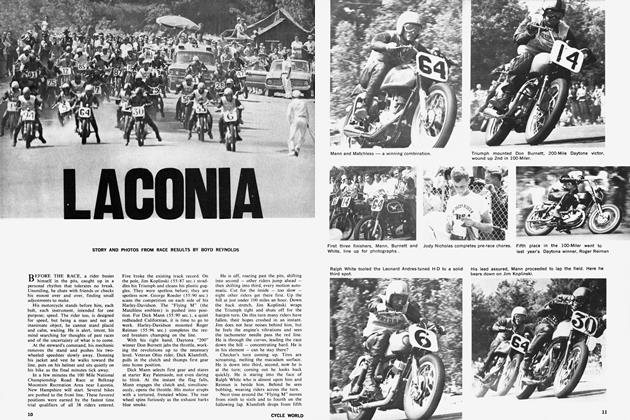

Laconia

SEPTEMBER 1962 By Boyd Reynolds -

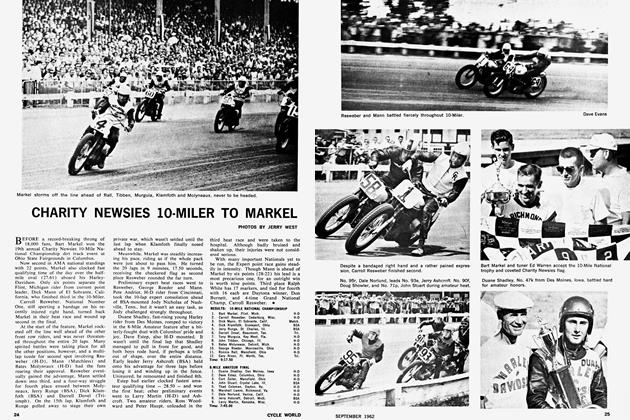

Charity Newsies 10-Miler To Markel

SEPTEMBER 1962 -

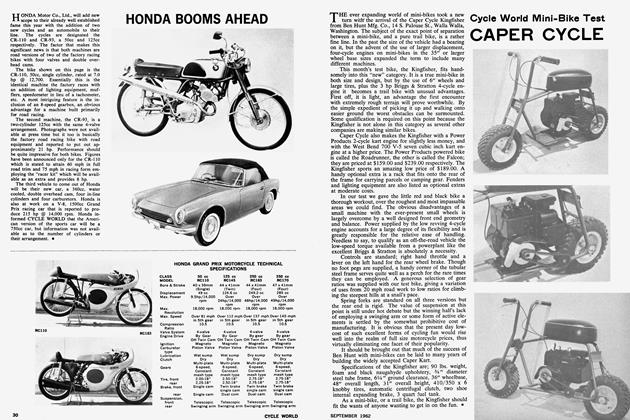

Cycle World Mini-Bike Test

Cycle World Mini-Bike TestCaper Cycle

SEPTEMBER 1962 -

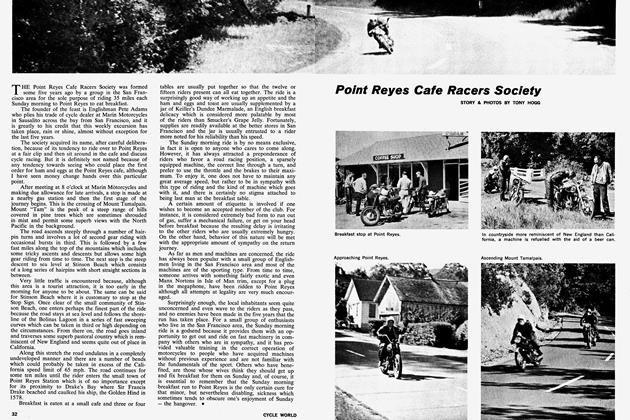

Point Reyes Cafe Racers Society

SEPTEMBER 1962 By Tony Hogg