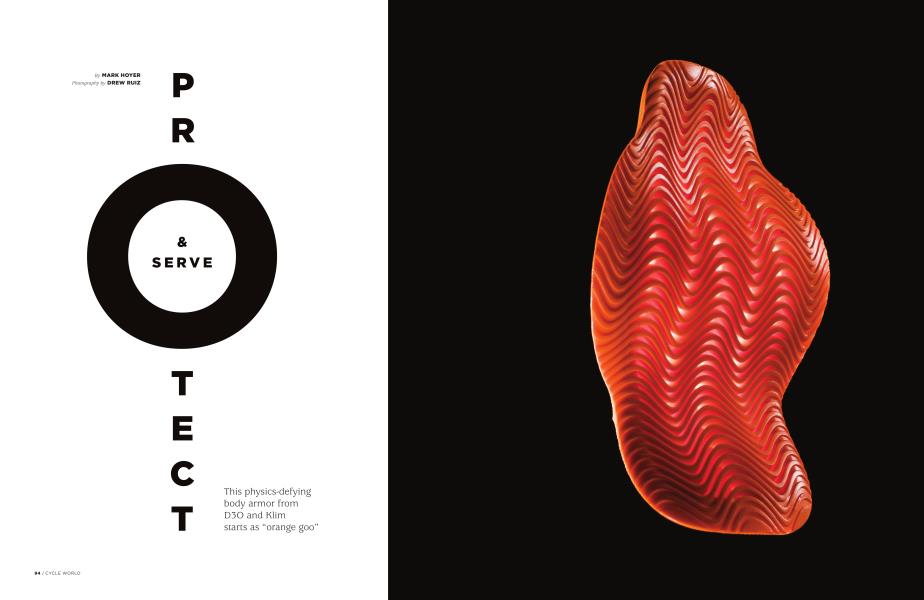

Protect & Serve

This physics-defying body armor from D30 and Klim starts as “orange goo”

January 2 2018 Mark HoyerThis physics-defying body armor from D30 and Klim starts as “orange goo”

January 2 2018 Mark HoyerPROTECT & SERVE

MARK HOYER

This physics-defying body armor from D30 and Klim starts as “orange goo”

D30 really does call the base material used in its armor “orange goo,” but that’s mostly because those of us who are not scientists or engineers glaze over when we hear “dilatants are a non-Newtonian fluid.”

But D30 (pronounced dee-three-oh) works the way it does because this liquid goo increases in viscosity when shear is applied, contrary to ideas presented by Sir Isaac (also English, like D30 the company) in, what else, but the notion of Newtonian fluid. Eyes glazed yet?

Goo’s magic quality is that when it gets hit, it sort of “locks up” and absorbs the impact. Those scientists will wince at “locks up,” but this is how most of us would understand the material’s behavior. D30’s secret to success with the base orange-goo dilatant is in finding ways to combine it with other polymers and deliver it in forms used by many different manufacturers that require shock-absorbing qualities in their products: phone cases, work gloves, kneepads, and shoe inserts. And, as they say, more.

Design and development takes place in D30 Labs’ South London headquarters. In one room, a CNC machine with a fine milling tool carves out molds so the lab can pour different test forms. In another room is test equipment for CE certification, including head forms with sensors (military and sports helmets) and a most wonderfully complex impact tester that drops machined forms on pads placed over anvils. There are ways to make the gear hot, cold, and wet to ensure it meets certifications in the required environment.

LP1: LIMB PROTECTION 1, D30’S STANDARD VERSION OF AERO PRO CERTIFICATION: AERO PRO PASSES CE LEVEL 2 TESTING FOR AMBIENT, WET, HOT, AND COLD COVERAGE: REWORKED DESIGN INCREASES COVERAGE BY 44 PERCENT AIRFLOW: KLIM CLAIMS FIVEFOLD INCREASE IN AIRFLOW WEIGHT: NEW ARMOR SET APPROXIMATELY ONE-HALF-POUND LIGHTER THAN PREVIOUS VERSION

We are most interested in the CE-certified motorcycle armor. Goo is combined with what D30 calls set foam. The armor is made by injecting the liquid recipe into a mold, where it expands (essentially foams up) to form the parts you see here. One of D30’s American partners is Klim, and this partnership resulted in joint-specific armor for shoulders, knees, and elbows designed to expand the area of protection and increase breathability. This Klim Aero Pro D30 armor was introduced in the 2018 Badlands Pro jacket and pants.

The qualities of D30 allow the armor to be thinner than many other types of protection, and also more flexible when not under impact’s duress. In the older Klim Badlands Pro jacket and pants I’ve used for adventure riding the past few years, my only complaint was that areas of my body that the armor covered were hot, and airflow in other parts of the suit was better. These pads are claimed to improve breathability fivefold while offering 44 percent more coverage.

The best motorcycle gear sort of disappears when you’re wearing it, allowing a rider the greatest mobility while waiting to do its protective job. Orange goo goes a long way toward achieving this kind of balance.