The Tire Revolution Spreads

TREAD RUBBER BECOMES A COMPOSITE MATERIAL

August 1 2017 Kevin CameronTREAD RUBBER BECOMES A COMPOSITE MATERIAL

August 1 2017 Kevin CameronTHE TIRE REVOLUTION SPREADS

IGNITION

TDC

TREAD RUBBER BECOMES A COMPOSITE MATERIAL

KEVIN CAMERON

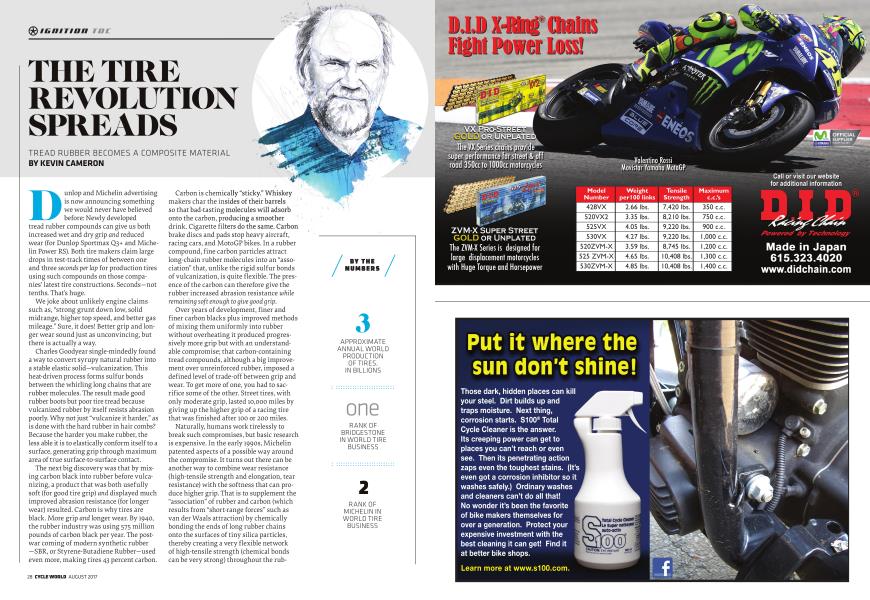

Dunlop and Michelin advertising is now announcing something we would never have believed before: Newly developed tread rubber compounds can give us both increased wet and dry grip and reduced wear (for Dunlop Sportmax Q3+ and Michelin Power RS). Both tire makers claim large drops in test-track times of between one and three seconds per lap for production tires using such compounds on those companies’ latest tire constructions. Seconds—not tenths. That’s huge.

We joke about unlikely engine claims such as, “strong grunt down low, solid midrange, higher top speed, and better gas mileage.” Sure, it does! Better grip and longer wear sound just as unconvincing, but there is actually a way.

Charles Goodyear single-mindedly found a way to convert syrupy natural rubber into a stable elastic solid—vulcanization. This heat-driven process forms sulfur bonds between the whirling long chains that are rubber molecules. The result made good rubber boots but poor tire tread because vulcanized rubber by itself resists abrasion poorly. Why not just “vulcanize it harder,” as is done with the hard rubber in hair combs? Because the harder you make rubber, the less able it is to elastically conform itself to a surface, generating grip through maximum area of true surface-to-surface contact.

The next big discovery was that by mixing carbon black into rubber before vulcanizing, a product that was both usefully soft (for good tire grip) and displayed much improved abrasion resistance (for longer wear) resulted. Carbon is why tires are black. More grip and longer wear. By 1940, the rubber industry was using 575 million pounds of carbon black per year. The postwar coming of modern synthetic rubber —SBR, or Styrene-Butadiene Rubber—used even more, making tires 43 percent carbon.

Carbon is chemically “sticky.” Whiskey makers char the insides of their barrels so that bad-tasting molecules will adsorb onto the carbon, producing a smoother drink. Cigarette filters do the same. Carbon brake discs and pads stop heavy aircraft, racing cars, and MotoGP bikes. In a rubber compound, fine carbon particles attract long-chain rubber molecules into an “association” that, unlike the rigid sulfur bonds of vulcanization, is quite flexible. The presence of the carbon can therefore give the rubber increased abrasion resistance while remaining soft enough to give good grip.

Over years of development, finer and finer carbon blacks plus improved methods of mixing them uniformly into rubber without overheating it produced progressively more grip but with an understandable compromise; that carbon-containing tread compounds, although a big improvement over unreinforced rubber, imposed a defined level of trade-off between grip and wear. To get more of one, you had to sacrifice some of the other. Street tires, with only moderate grip, lasted 10,000 miles by giving up the higher grip of a racing tire that was finished after 100 or 200 miles.

Naturally, humans work tirelessly to break such compromises, but basic research is expensive. In the early 1990s, Michelin patented aspects of a possible way around the compromise. It turns out there can be another way to combine wear resistance (high-tensile strength and elongation, tear resistance) with the softness that can produce higher grip. That is to supplement the “association” of rubber and carbon (which results from “short-range forces” such as van der Waals attraction) by chemically bonding the ends of long rubber chains onto the surfaces of tiny silica particles, thereby creating a very flexible network of high-tensile strength (chemical bonds can be very strong) throughout the rubber. This in effect turns the tread compound into a composite material, like fiberglass, which also gets its high-tensile strength from embedded fibers. Relatively few of the strong chemical bonds joining rubber and silica could provide the same or greater tensile strength as a great many more of the “associational bonds” between carbon particles and rubber—resulting in a softer material.

BY THE NUMBERS

3 APPROXIMATE ANNUAL WORLD PRODUCTION OFTIRES, IN BILLIONS

one RANK OF BRIDGESTONE IN WORLD TIRE BUSINESS

2 RANK OF MICHELIN IN WORLD TIRE BUSINESS

This development may have come about by accident. What was originally developed as a rubber cure modifier, something called TESPT, turned out to produce improved visco-elastic compound properties when combined with silica. The first practical application was an increase in wet grip (1992). Turns out TESPT also acts to make silica more mixable into rubber; it modifies the silica surface. Now there is a wide literature on such silane “coupling agents.” One of whose applications is prim-

ing human tooth surfaces so that UV-cure polymers can adhere as fillings. During 2015, Michelin literature tells us, 700 million euros were devoted to rapidly developing this system of bonding rubber chains to silica particles.

Despite legendary Michelin secrecy, word gets around. New silanes, designed specifically to get around Michelin’s patents, were developed as other rubber companies explored the new possibilities. Bridgestone published information on its program of attaching “functional groups” to the ends of rubber chains— molecular groups whose purpose was to bond strongly to silica particles. A new day was coming.

During the 1990s legendary tuner Erv Kanemoto noticed that in addition to the dark, semi-wet look of hot conventional race tire rubber, there was now also a dry, dusty grayish-looking tread rubber on some race tires. This later revealed the fast-developing silica technology, which wasted no time in moving some rubber compounds that had once been rain-only onto dry tires.

N0WTHI5 NEW WAY TO COMBINE THE TENSILE AND TEAR STRENGTH THAT REDUCES WEAR WITH GREATER SOFTNESS THAT BOOSTS BOTH WET AND DRY GRIP IS NO LONGER A LABORATORY PROCESS...

In 2009 when Colin Edwards Jr. first raced on the Bridgestone tires that became spec in MotoGP that year, he was amazed, saying, “I don’t know how it’s possible, but you can just keep on loading up those Bridgestone fronts on the brakes and they don’t let go.” When I asked Marc Marquez, in his first year in MotoGP, what he found most unusual, he replied, “The Bridgestone front tire. You can just keep pushing on it.”

Now this new way to combine the tensile and tear strength that reduces wear with greater softness that boosts both wet and dry grip is no longer a laboratory process, suitable only for specialized activities like roadracing. It has been commercialized for consumer use in production tires.

View Full Issue

View Full Issue

More From This Issue

-

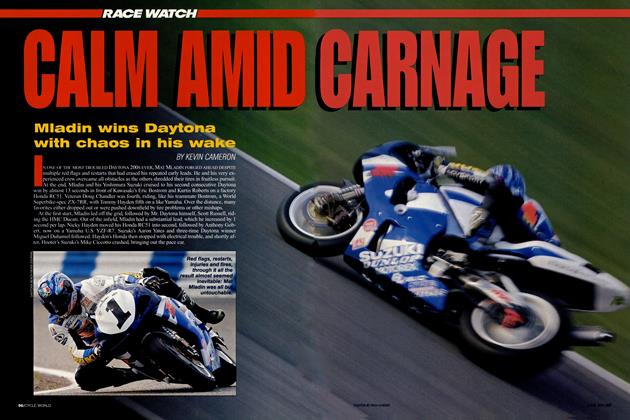

Race Watch

Race WatchA Great One Remembered

AUGUST 2017 By Larry Lawrence -

Service

ServiceService

AUGUST 2017 By Ray Nierlich -

2017 Ducati 1299 Super-Leggera

AUGUST 2017 By Don Canet -

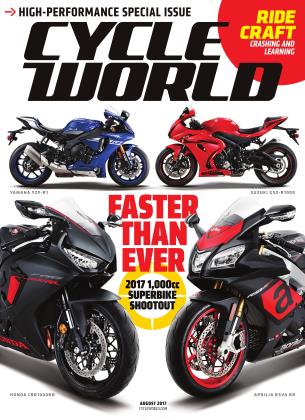

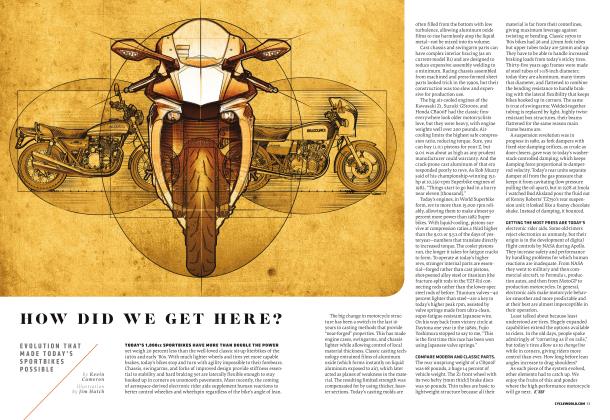

How Did We Get Here?

AUGUST 2017 By Kevin Cameron -

Cw Comparison

Cw ComparisonLife On the Street

AUGUST 2017 By B. A. -

Up Front

Up FrontRisk

AUGUST 2017 By Mark Hoyer