SOLUTIONS

IGNITION

TDC

SOMETIMES IT'S BETTER TO BE PRACTICAL THAN PERFECT

KEVIN CAMERON

It’s fascinating to see the common technologies that run through all machines. Yet quite often, specific solutions have more to do with how much time or money can be spent on them. Harley, in the original Evolution engine, chose to retain the heads and barrels with long studs rather than to provide the cylinder with a base flange, bolt that to the crankcase, and then bolt the head to the top of the barrel. Velocette, in developing its 35OCC KTT racing single, had cylinder base flange breakages as a result of the very high compression ratios some customers were using with alcohol fuel. Instead of switching to long, slender studs as Harley would in the future, Velocette just made its cylinder’s base flange thicker. A thicker flange doesn’t always work. I’ve seen more than one such thick flange, still bolted to the crankcase of a souped-up Norton Commando but with the cylinders and head somehow missing.

When in the 1930s the aircraft radial piston engine became an element in national military planning, such modest solutions weren’t even considered. Instead, cylinders were made from seamless steel tubing, heated red-hot in furnaces, and then placed in a special forge called an “upsetter” that squeezed the material into forming a bolting flange. Forged bolting flanges could be both light and reliably strong.

These three solutions to the same basic problem are not good, better, best. Each one was appropriate to the resources available to its manufacturer. Velocette, always a small company, just made the base flange thicker because that could be done without expensively changing the basic design. Harley-Davidson, able to afford to retool its entire top end, could choose its long-stud solution. The special quality of long studs is their lengthwise stretchiness, which can maintain the clamp load required to make the head gaskets seal, even though both head and barrel are aluminum, and so expand considerably at operating temperature. Only a major industry, backed by government clout, could afford to forge cylinders with integral bolting flanges.

Crankshafts for certain large marine engines were shrink-fitted together out of separate elements, just as Honda assembled the cranks for its 18,000rpm six-cylinder 250 racer of 1967. In the first case, the motivation might have been that the factory was not tooled to produce and machine such huge one-piece crankshafts. We can imagine building houses in a giant 3-D printer, but since my builder has no such machine, I have a house fabricated from individual studs, joists, and rafters.

Honda’s problem was different.

In 1960s motorcycle design, rolling bearings were still believed to offer lower friction than the plain bearings that autos had by then almost universally adopted. To avoid the problems of trying to make and run split-and-bolted roller con-rods (chain saw companies were doing it successfully with fracture-split rods but at much lower horsepower per cubic inch), Honda chose one-piece rods and a crank press-fitted together from separate elements. Because press-fits have limited grip, Honda took power from the center of the six’s crank and then made crankpins three and four large enough that their press-fits could transmit the power from cylinders one and two, and five and six, without slippage, and then it made crankpins two and five slightly smaller and finally crankpins one and six smaller yet.

The same problem was tackled in aviation. Was it nobler in the mind to have a one-piece crankshaft and two-piece, bolted-together master connecting rods? Or to somehow fasten together a multi-piece crank to have the luxury of super-strong one-piece rods? So engines were built both ways. The 14-cylinder radiais that powered WWII B-24 bombers had split-and-bolted rods and one-piece cranks, but the 18-cylinder engines in P-47S, F4US, and postwar DC-6 airliners had multi-piece cranks and onepiece rods.

BY THE NUMBERS

1984 THE YEAR HARLEY’S AIR-COOLED 45-DEGREE EVO ENGINE MADE ITS DEBUT

12,571 FROM 1940 TO 1953, CHANCE-VOUGHT BUILT THIS MANY F4U CORSAIRS. (THE HONDURAN AIRFORCE USEDTHE PLANE UNTIL 1979!)

-341 TEMPERATURE, IN FAHRENHEIT, OFTHE LIQUID NITROGEN USEDTO IMMERSE THE YAMAHA R1’S CONNECTING RODS BEFORE THE FRACTURE-SPLIT PROCESS BEGINS

Ultimately it can come down to engineering over design. If you tool to build your engine one way, then have problems, it could take too long to back out, redesign, and retool to do it the other way. Several aircraft engine designs, in fact, were canceled because they were taking too long to reach reliability. So you look for ways to make your design choice work. The biggest problem was keeping the separate, bolted-inplace cap of a two-piece rod from moving around relative to the rod itself. Such movement pinched the big master rod bearing, compromising its function.

Yet recently we saw that Yamaha, in the titanium rods of its new YZF-Ri sportbike, had to

tackle this very same problemhow to keep a separate rod cap from moving relative to the rod. Such solutions as dowel pins, serrations, and machined steps have been used but they add cost in extra setups, tooling, and machining steps. This stuff has to sell at a competitive price, and that means we can’t slow the whole production line while elderly master machinists perform miracles of craftsmanship. So Yamaha’s metallurgists found ways to fracture-split the titanium rod cap from a one-piece rod forging. The resulting complex mating surfaces, as irregular as they are, aligned the cap to the rod perfectly—no chance of the cap sliding into misalignment. Those surfaces are produced by fracture, in a tiny fraction of a second.

Earlier, I referred to the springiness of long studs being useful in maintaining clamp load as parts expand and contract

in heating and cooling. The reverse is also true—the shorter you make a bolt or stud, the less springy stretch range it has, so the more difficult it is to keep tight. With a short stud, it doesn’t take too much vibration or stress to unload what tension it has, making the nut vulnerable to unscrewing. The wonderfully strong steel base flanges of aircraft radiais were fastened to the crankcase with short studs, and the “unloading problem” required that each be secured with a springy patent locknut called a “Palnut.”

We can’t make everything in a mechanism perfect. To hit the market before it moves on to somebody else’s product, you have limited time to plan and tool. There’s no time for risky experiments, no time to do it over, so you call upon detail engineering to make your choices work. You hope. CTMJ

YAMAHA’S METALLURGISTS FOUND WAYS TO FRACTURESPLIT THE TITANIUM ROD CAP FROM A ONE-PIECE ROD FORGING.

THE RESULTING COMPLEX MATING SURFACES ALIGNED THE CAP TO THE ROD PERFECTLY.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

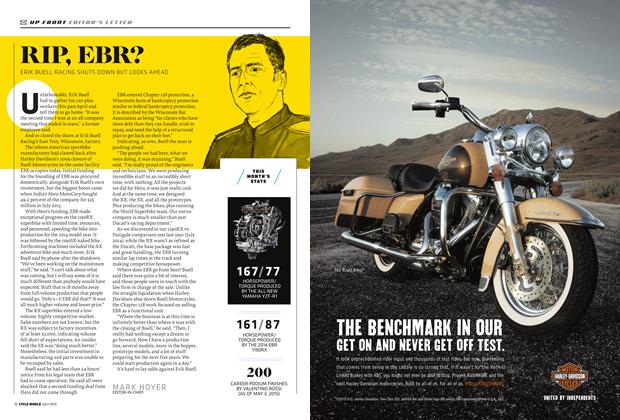

Up FrontRip, Ebr?

July 2015 By Mark Hoyer -

Intake

IntakeIntake

July 2015 -

Ignition

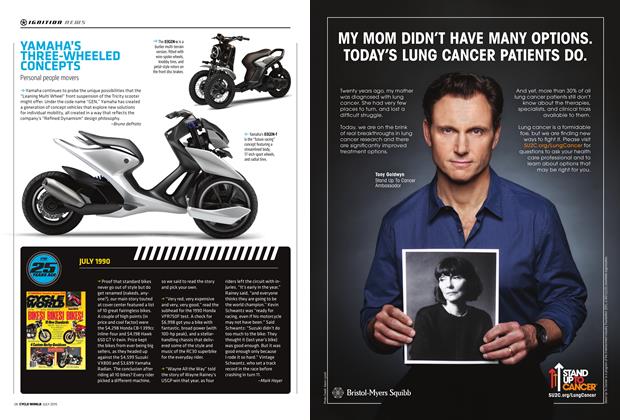

IgnitionYamaha's Three-Wheeled Concepts

July 2015 By Bruno Deprato -

Ignition

IgnitionCw 25 Years Ago July 1990

July 2015 By Mark Hoyer -

Ignition

IgnitionTwo-Up Training Don't Rock the Boat

July 2015 By John L. Stein -

Ignition

IgnitionThe Recently Undead

July 2015 By Paul d’Orléans