Alloy connection

TDC

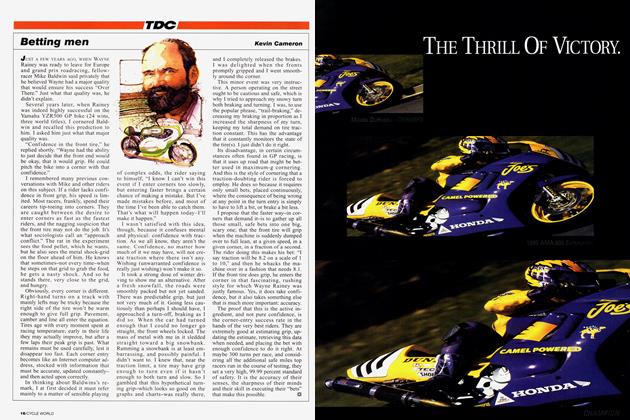

Kevin Cameron

A FEW MONTHS AGO, I WROTE ABOUT the 1947 Triumph Speed Twin. I have always wondered about the origin of this engine’s aluminum connecting rods, seen today only in drag racing.

Unlike steel, aluminum has no fatigue limit-a level of stress below which a part’s lifetime can be essentially infinite. Aluminum rods therefore have the reputation of early failure. Why did Edward Turner, ambitious and commercial-minded, choose them for the original Speed Twin of 1937?

Pure aluminum is soft, weak and expensive to extract from its ore. At the turn of the century it was a curiosity essentially without use. In 1909, a German, Alfred Wilm, decided to try alloying it with copper, then heating and quenching it, in an attempt to give it strength. To his disappointment, this treatment seemed initially to produce little or nothing. But to his surprise, retesting the metal a day or so later revealed a remarkable strength increase, Wilm had discovered age-hardening.

Wilm sold his process to a German firm that made age-hardened aluminum widely known as Duralumin. It was soon used in zeppelin frames, The process was also sold to Vickers in England. Eighteen months later, a connecting-rod was machined from solid Vickers Duralumin, fitted to a

490 Norton, and ridden to fastest time of the day, July 20th, 1912, at the then-new Brooklands Speedway. The light metal con-rod and a very thin steel piston gave this machine the ability to rev to 4000 rpm.

The British National Physical Laboratory worked at elaborating the usefulness of age-hardened aluminum, developing a new aluminum-coppernickel-magnesium system they called Y-Alloy. It showed outstanding strength even when hot-ideal for pistons.

An English engineering firm, Peter Hooker, Ltd., experimented with the new metal with a view to making forgings of it. After much experiment, a method was found that worked. Hedley Thomson, who had done much of this work, became a little silly over the

potential of the new stuff. He had it madc into piston rings, which, of course, wore out instantly. A wartime associate of Thomson was Frank Halford, an engineer, motor sportsman, flyer and Brooklands racer. Halford had worked with combustion pioneer Harry Ricardo in producing and testing a racing four-valve head for Triumph Singles. Halford saw the value of smaller cylinders, operating at very high speed-the essential concept of

the modern motorcycle engine. He now designed (1923) a six-cylinder, 90-cubic-inch, turbocharged racing auto engine, and equipped it with forged, Y-Alloy pistons and connecting rods-likely the first such use of forged aluminum. It was reliable at a then-astounding 6000 rpm.

A short time later, Halford was involved in forging swords into plowshares-in this case building new civil aircraft engines from World War I surplus. Halford’s eventual Cirrus and Gipsy light aviation engines also used

aluminum rods forged from Y-Alloy. The engines began at a low piston speed of 1750 feet per minute (today’s Superbikes run to 4000-4500 fpm) and gradually worked up toward 3000 fpm. Their forged-aluminum rods continued to give good service.

Meanwhile, Hooker had folded and its forging equipment had been bought by another avid Brooklands racer, W.C. Devereux. He called his new firm High Duty Alloys, and developed a whole series of aluminums under the name Hiduminium.

During this time, the eventual designer of the Triumph Speed Twin, Edward Turner, was a motorcycle dealer. He designed a machine of his own and had bigger plans. In 1928, he was hired by Ariel, where he designed the famous Ariel Square Four, an engine with two geared twin-cylinder cranks, one ahead of the other. While working with a single-crank test engine, either he or fellow-designer Val Page realized (this matter remains at issue) that a parallel-Twin could be a simple and attractive follow-on to the Singles then dominant in English motorcycling. It would have smoother pulling (twice as many firing impulses) and more performance potential because of its shorter stroke (allowing more revs) and greater valve area (for more airflow). But with both pistons rising and falling together, this form of Twin would vibrate like a Single. Hard. Unless something could be done about the weight of its reciprocating parts.

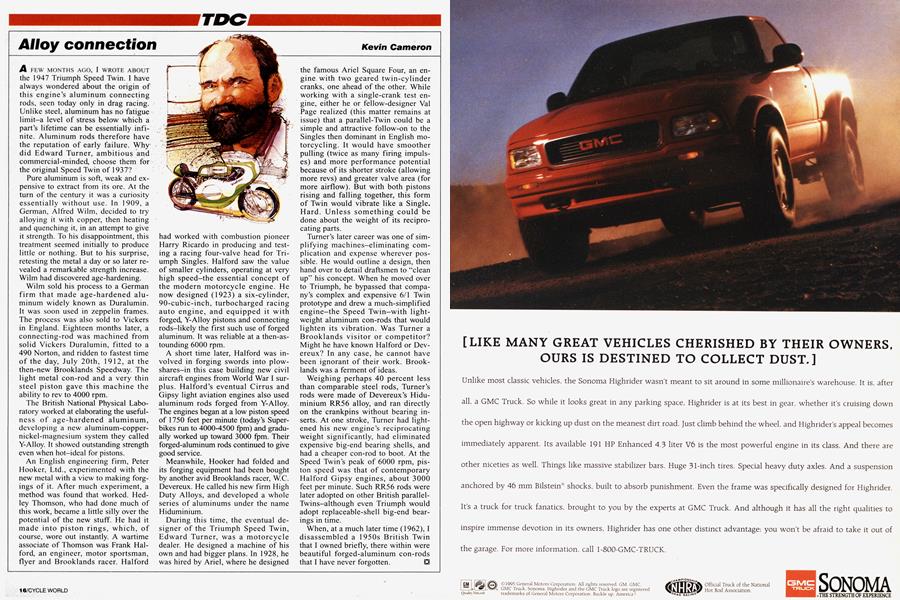

Turner’s later career was one of simplifying machines-eliminating complication and expense wherever possible. He would outline a design, then hand over to detail draftsmen to “clean up” his concept. When he moved over to Triumph, he bypassed that company’s complex and expensive 6/1 Twin prototype and drew a much-simplified engine-the Speed Twin-with lightweight aluminum con-rods that would lighten its vibration. Was Turner a Brooklands visitor or competitor? Might he have known Halford or Devereux? In any case, he cannot have been ignorant of their work. Brooklands was a ferment of ideas.

Weighing perhaps 40 percent less than comparable steel rods, Turner’s rods were made of Devereux’s Hiduminium RR56 alloy, and ran directly on the crankpins without bearing inserts. At one stroke, Turner had lightened his new engine’s reciprocating weight significantly, had eliminated expensive big-end bearing shells, and had a cheaper con-rod to boot. At the Speed Twin’s peak of 6000 rpm, piston speed was that of contemporary Halford Gipsy engines, about 3000 feet per minute. Such RR56 rods were later adopted on other British parallelTwins-although even Triumph would adopt replaceable-shell big-end bearings in time.

When, at a much later time (1962), I disassembled a 1950s British Twin that I owned briefly, there within were beautiful forged-aluminum con-rods that I have never forgotten.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontDoin' the Wave

June 1995 By David Edwards -

Leanings

LeaningsDucks Unlimited

June 1995 By Peter Egan -

Letters

LettersLetters

June 1995 -

Roundup

RoundupBandits Coming Soon To Your Neighborhood

June 1995 By Robert Hough -

Roundup

RoundupYamaha's Surprise Single

June 1995 By Robert Hough -

Roundup

RoundupVincent Black Eagle Taking Shape

June 1995 By Robert Hough