DETECTIVE STORY

IGNITION

TDC

THE EVOLUTION OF BEARINGS

KEVIN CAMERON

The crankshafts and connecting rods of most four-stroke motorcycle engines today turn on plain, or journal, bearings.

The journals of the crank are ground to a smooth and truly cylindrical shape, and the main and rod bearings consist of semi-circular steel shells surfaced with a thin layer of a special metal alloy, typically a so-called "white metal." This thin layer must satisfy seemingly mutually exclusive requirements. First, it must be soft enough to embed potentially damaging wear or contaminant particles, which would otherwise scratch, damage, and eventually destroy the smooth journal. Second, the material must be strong enough to support bearing loads of thousands of pounds per square inch—loads generated by combustion pressure and by the inertia forces arising from the rapid stopping and starting of the pistons. Fortunately, type metal used in printing offered a starting point. It consisted of low-melting-point lead, made stronger by alloying with tin (lead-tin alloys are called "pewter" and were used to make dinner plates in former times) and made harder by adding the element antimony, a brittle metal.

In early days, piston-engine loads and speeds were lower, and thick layers of bearing metal were used, but as engine performance rose, fatigue failures occurred in the bearing metal. Analysis showed that shear stress in the bearing metal produced cracks that moved downward to the supporting shell. There, they turned sideways, eventually causing small islands of the bearing metal to separate from the shell. This was called "picking out." When bearing caps were removed and a shaft lifted out, such bits would be found to have separated from the bearing itself.

A solution was sought when this problem caused con-rod bearing failures in USdesigned V-12 "Liberty" aircraft engines sent to France during World War I. US Engineering Officer, E.S. MacPherson, decided to

consult a local expert, Ettore Bugatti, who designed and produced high-performance cars bearing his name. MacPherson decided that the thin, white metal, or Babbitt, as it is called in the United States, would resist cracking better if there were less of it. Bugatti's bearings, made with much thinner white metal, were highly successful.

In the early 1920s, Norm Gilman at Allison Engineering in Indianapolis added another dimension: a stronger yet still embeddable bearing alloy consisting of a strong matrix of copper filled with lead.

After World War II, the use of steel-shell journal bearings coated with a thin layer of bearing metal spread rapidly, eventually displacing rolling bearings even from Formula 1 engines. One of several important innovations in Honda's groundbreaking 1969 CB750 Four was the use of such bearings, and their use has now become common in motorcycle engines, both production and racing. The ball main bearings long used by Ducati in its V-twins have, at last, in the recently introduced Panigale 1199, been replaced by journal bearings. This satisfied a longtime ambition of Massimo Bordi, designer of the original "Ottovalvole" 851 Ducati engine. Plain bearings are much stiffer radially than rolling bearings, provide much greater damping, and they easily carry heavier loads for greatly extended periods.

Environmental legislation has recently made it difficult to use materials such as lead, cadmium, and arsenic, all of which find application in bearing metals. We all know that in a similar fashion, chlorofluorocarbons, such as Freon, are no longer used as refrigerants because of their ozone-depleting action. The so-called "heavy metals" have been found to cause nervous-system problems and will in time be removed from industrial use. What to put in their place? This quest is described in the book Changes in Plain Bearing Technology by Rolf Koring, published in the US by the Society of Automotive Engineers (SAE).

BY THE NUMBERS

44

OUT-OF-DATE PA000CI( PASSES HANGING ON A PEG IN OUR I(ITCHEN

29

NUMBER OF WELL THUMBED VOLUMES OF MOTOCOURSE THAT I OWN

0

TEXT MESSAGES I HAVE SENT, SO FAR, FROM MY NEW COMPANY PHONE

Present bearing metals are alloys of tin, antimony, and cadmium, lead having been mostly eliminated already for environmental/health reasons. Bearing metals are strengthened by the same mechanisms used to strengthen other metals, and methods for this were applied to strengthening type metal as early as 1683. Tiny intermetallic crystals of tin and antimony act to prevent the sliding motion of one atomic plane over another. These crystals form as the molten alloy cools and the material can no longer hold them in solution. This is called "precipitation hardening" because the tiny crystals form, or are "precipitated," from the melt as they are forced out of solution as temperature falls.

A tiny addition of highly poisonous arsenic acted as a nucleating agent, causing greater numbers of smaller tin-antimony crystals to form (a pinch of titanium performs this function in gas-turbine alloys and in the exhaust valves of 500CC BSA Gold Stars).

Research showed that silver could replace arsenic in this role. Out with the arsenic!

More research showed that even tiny amounts of lead could be a problem, as the soft metal formed lowmelting-point zones on the bearing. Tested at room temperature, these bearings passed all standard tests.

But tested at actual bearing operating temperature, closer to the melting point of these zones, they became low-strength areas of weakness, inviting failure. Out with the lead!

Cadmium acted to harden the matrix of the bearing material. Alloying with an element whose atoms are a different size has a hardening effect similar to that of tiny precipitated crystals; it makes it harder for planes of atoms to slide over one another, thus hardening the material. Zinc had been passed over for years, as it was known to reduce fluidity and add manufacturing difficulty. Was this the whole story? Koring's group decided to repeat the tests, this time using much less zinc. They found that this increased the compressive strength of the material, just as cadmium had, and was not a problem in manufacturing. Zinc could do the job. Out with the cadmium!

PLAIN BEARINGS IN THE -iYDRAU LIE TURBINES USED N HYDRO ELECTR PU WE P ANTS HAVE BEEN KN WN 0 OPERA11 W HOUT SHUTDOWN OR 50 YEARS.

Koring notes the durability of modern plain bearings in his first chapter. Auto engines typically run 3,000 hours, and their bearings have usually not failed when they are taken out of service. In large industrial or marine piston engines, plain bearings may need replacement after 20,000 hours, and in smooth-running turbines (gas or steam), this becomes 50,000 hours (almost six years). Plain bearings in the hydraulic turbines used in hydroelectric powerplants have been known to operate without shutdown for 50 years. And so they should. So long as oil always separates the bearing surfaces, wear is impossible. ETU

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontMotorcycling Manual

DECEMBER 2013 By Mark Hoyer -

Intake

IntakeIntake

DECEMBER 2013 -

Ignition

IgnitionSpied! Harley's New Indian

DECEMBER 2013 By Rishad Cooper -

Ignition

IgnitionDecember 1988

DECEMBER 2013 By Andrew Bornhop -

Features

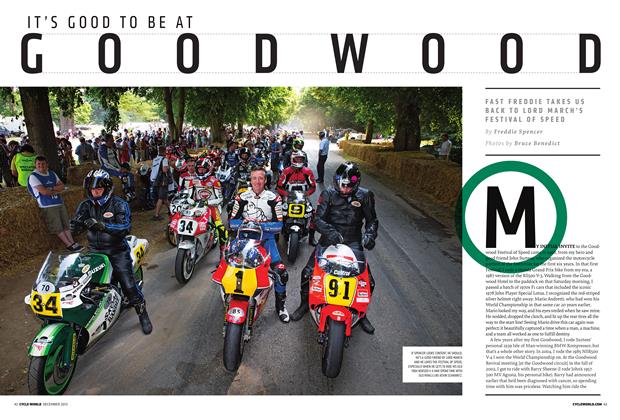

FeaturesIt's Good To Be At Good Wood

DECEMBER 2013 By Freddie Spencer -

Features

FeaturesFlatland Freighters

DECEMBER 2013 By Matthew Miles