Fashion and Engineering

TDC

KEVIN CAMERON

HOW STRANGELY TECHNOLOGY changes. It would be comforting to think that it follows the guidance of reason, but often enough it seems more like fashion.

Why does technological change sometimes take so long? Replaceable three-layer plain bearings were developed for heavy service in the large piston aircraft engines of WWII, and at war’s end this was a mature technology, ready for adoption by the civilian world. Its use made sense, as it provided reliability, long life and easy “resize-and-rebuild” serviceability.

Yet rolling-element bearings—balls, rollers and needles—persisted in motorcycle engines with little challenge until Honda broke with tradition in 1969 by giving its pioneering CB750 Four a one-piece forged crankshaft spinning in plain bearings. Even then, the answering large four-stroke designs from Kawasaki (1973) and Suzuki (1976) persisted with rolling-element bearings. Suzuki engines in Pro Stock Motorcycle drag racing use them to this very day.

I’ve been doing a bit of historical reading lately and getting a glimmer of how it could take decades for motorcycles to catch up to cars in the adoption of plain bearings and rugged one-piece crankshafts. It has to do with tradition being too strong, too well-accepted to be challenged.

In 1923, two Italian engineers, Piero Remor and Carlo Gianini, designed an inline four-cylinder motorcycle engine that was mounted transversely. It was an important moment, for from that beginning have descended all of today’s inline-Four motorcycle engines.

Only the year before, Fiat had broken with tradition in giving its six-cylinder Type 404 GP car engine only two valves per cylinder, and in boldly supporting its long-stroke crank and rods on 100 percent rolling-element bearings. Two valves could do the work of the previously accepted four because they were very large, their size accommodated by setting intakes and exhausts at a large angle to each other—96 degrees. Twenty-five years later, Remor would refine his four-cylinder concept as Güera’s postwar Grand Prix 500. Remor did not adopt the three-layer plain bearing as did BRM, Ferrari and other forward-thinking builders. He continued to use the roller crankshaft he was familiar with. And he gave the new Güera Four a long-stroke roller crank and wide pre-war valve angle of 90 degrees— not the 58 or 60 degrees being adopted elsewhere (Guzzi, Ferrari, BSA) for its virtues of compactness, speedier combustion and reduced heat loss to coolant. Later, Güera’s 90 degrees would be increased to 100 degrees.

Two years later (1950), Remor left Güera for MV Agusta, where he designed the same air-cooled four-cylinder engine again—with a long-stroke (52 x 58mm cylinder dimensions) roller crank and two valves per cylinder, set at that same prewar 90-degree included angle.

As antique powerplants of this kind won so many GP races, Honda, in entering GP racing, continued many of their features—among them, roller cranks built up from many separate parts.

Meanwhile, engineers could hear through the grapevine about comparative tests run at Ferrari in which two V-12 engines—one with a roller crank, the other with one-piece crank and three-layer plain bearings—were extensively tested. The plain-bearing engine made more power and showed greater reliability and durability.

It’s not easy to build multi-cylinder cranks with rolling bearings. If the crank is made in one piece, ways must be found to make the halves of split bearings, cages and con-rods align seamlessly and operate reliably. If rods and bearings are to be in one piece, the crank must be separable into pieces to permit assembly of such bearings onto its journals. That means finding methods of assembly that

can handle the stresses of high rpm, of the power produced and of frequent rpm spikes as harsh suspension lets the drive wheel leave the pavement. Honda, Moto Guzzi, Mercedes and Porsche found ways. Honda pressed its 1960s roadracing cranks together, cutting stress in half by taking power from a gear at the center, not from one end. The others employed intricate radial splines—the so-called “Hirth couplings”—to assemble their cranks—held firmly together by hefty internal draw-bolts.

Honda’s engineering steamroller made its roller crank technology work clear past 21,000 rpm and very seldom had a failure in public. Mercedes gave its 1954 W196 GP car a Straight-Eight engine with built-up Hirth roller crank—also taking power from the center. Guzzi, trying several alternative crank and bearing solutions in its famous 500cc V-Eight, was supposedly preparing a one-piece, plain-bearing crank to be used in 1958. Roller cranks had been central elements of the mystique of cost-no-object highrpm racing motorcycle engines, built with fanatical precision but used like Kleenex.

There was a better way. Edward Turner, designer of the original “British Twin”—the Triumph Speed Twin of 1937—needed an easier way if his creation was to affordably replace simpler Singles. He gave it aluminum con-rods, their material running directly against the crankpins. Only later was this scheme replaced by three-layer insert bearing shells. Over at Royal Enfield, engineer Tony Wilson-Jones had shown in 1934 that rollers could be replaced by plain bearings. And finally, Honda stepped into the future by adopting them on the CB750.

I assume men could learn to walk in high-heeled shoes. Women have done so. But technique is not the deciding factor here. Fashion is. Current fashion dictates that women may wear high heels and that men may not. Honda could have built its 250cc six-cylinder RC-166 racing engine with a plain-bearing crank. That would have required a higher-volume oil system and greater oil-cooling capacity. But at the time, the force of history—Ing. Remor’s lifetime of immersion in the engineering culture of that 1922 Fiat and all that followed—dictated otherwise. Things get far enough down the road in a given direction and almost nobody questions them. The operant cause is, “We do things this way because everyone always has.” □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontRisk Management

JULY 2010 By Mark Hoyer -

Roundup

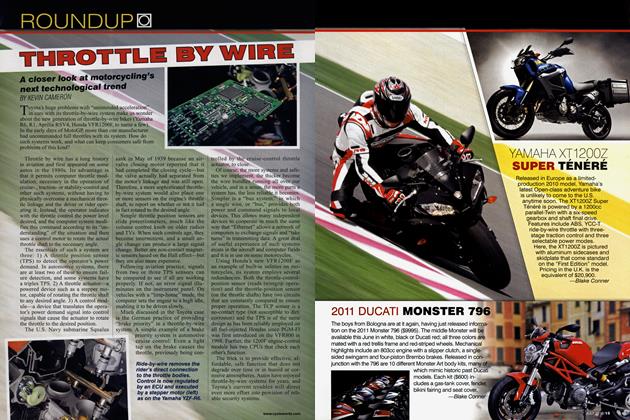

RoundupThrottle By Wire

JULY 2010 By Kevin Cameron -

Roundup

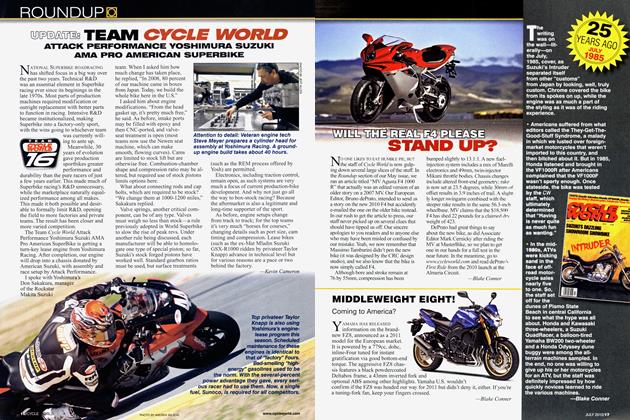

RoundupTeam Cycle World

JULY 2010 By Kevin Cameron -

Roundup

RoundupWill the Real F4 Please Stand Up?

JULY 2010 By Blake Conner -

Roundup

RoundupMiddleweight Eight!

JULY 2010 By Blake Conner -

Roundup

Roundup25 Years Ago July 1985

JULY 2010 By Blake Conner