Mixture formation

TDC

Kevin Cameron

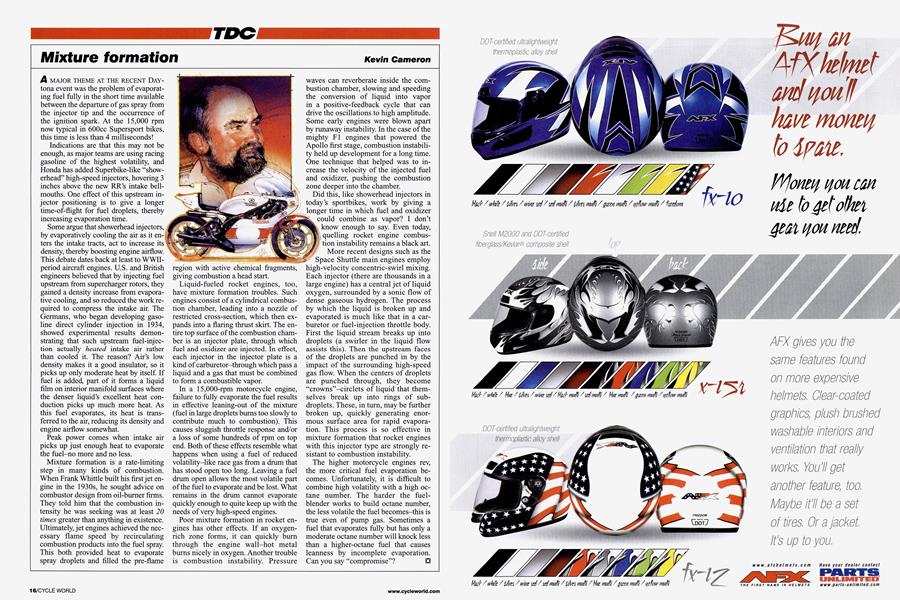

A MAJOR THEME AT THE RECENT DAYtona event was the problem of evaporating fuel fully in the short time available between the departure of gas spray from the injector tip and the occurrence of the ignition spark. At the 15,000 rpm now typical in 600cc Supersport bikes, this time is less than 4 milliseconds!

Indications are that this may not be enough, as major teams are using racing gasoline of the highest volatility, and Honda has added Superbike-like “showerhead” high-speed injectors, hovering 3 inches above the new RR’s intake bellmouths. One effect of this upstream injector positioning is to give a longer time-of-flight for fuel droplets, thereby increasing evaporation time.

Some argue that showerhead injectors, by evaporatively cooling the air as it enters the intake tracts, act to increase its density, thereby boosting engine airflow. This debate dates back at least to WWIIperiod aircraft engines. U.S. and British engineers believed that by injecting fuel upstream from supercharger rotors, they gained a density increase from evaporative cooling, and so reduced the work required to compress the intake air. The Germans, who began developing gasoline direct cylinder injection in 1934, showed experimental results demonstrating that such upstream fuel-injection actually heated intake air rather than cooled it. The reason? Air’s low density makes it a good insulator, so it picks up only moderate heat by itself. If fuel is added, part of it forms a liquid film on interior manifold surfaces where the denser liquid’s excellent heat conduction picks up much more heat. As this fuel evaporates, its heat is transferred to the air, reducing its density and engine airflow somewhat.

Peak power comes when intake air picks up just enough heat to evaporate the fuel-no more and no less.

Mixture formation is a rate-limiting step in many kinds of combustion. When Frank Whittle built his first jet engine in the 1930s, he sought advice on combustor design from oil-burner firms. They told him that the combustion intensity he was seeking was at least 20 times greater than anything in existence. Ultimately, jet engines achieved the necessary flame speed by recirculating combustion products into the fuel spray. This both provided heat to evaporate spray droplets and filled the pre-flame region with active chemical fragments, giving combustion a head start.

Liquid-fueled rocket engines, too, have mixture formation troubles. Such engines consist of a cylindrical combustion chamber, leading into a nozzle of restricted cross-section, which then expands into a flaring thrust skirt. The entire top surface of the combustion chamber is an injector plate, through which fuel and oxidizer are injected. In effect, each injector in the injector plate is a kind of carburetor-through which pass a liquid and a gas that must be combined to form a combustible vapor.

In a 15,000-rpm motorcycle engine, failure to fully evaporate the fuel results in effective leaning-out of the mixture (fuel in large droplets bums too slowly to contribute much to combustion). This causes sluggish throttle response and/or a loss of some hundreds of rpm on top end. Both of these effects resemble what happens when using a fuel of reduced volatility-like race gas from a dmm that has stood open too long. Leaving a fuel drum open allows the most volatile part of the fuel to evaporate and be lost. What remains in the drum cannot evaporate quickly enough to quite keep up with the needs of very high-speed engines.

Poor mixture formation in rocket engines has other effects. If an oxygenrich zone forms, it can quickly burn through the engine wall-hot metal burns nicely in oxygen. Another trouble is combustion instability. Pressure waves can reverberate inside the combustion chamber, slowing and speeding the conversion of liquid into vapor in a positive-feedback cycle that can drive the oscillations to high amplitude. Some early engines were blown apart by runaway instability. In the case of the mighty FI engines that powered the Apollo first stage, combustion instability held up development for a long time. One technique that helped was to increase the velocity of the injected fuel and oxidizer, pushing the combustion zone deeper into the chamber.

Did this, like showerhead injectors in today’s sportbikes, work by giving a longer time in which fuel and oxidizer could combine as vapor? I don’t know enough to say. Even today, quelling rocket engine combustion instability remains a black art. More recent designs such as the Space Shuttle main engines employ high-velocity concentric-swirl mixing. Each injector (there are thousands in a large engine) has a central jet of liquid oxygen, surrounded by a sonic flow of dense gaseous hydrogen. The process by which the liquid is broken up and evaporated is much like that in a carburetor or fuel-injection throttle body. First the liquid stream breaks up into droplets (a swirler in the liquid flow assists this). Then the upstream faces of the droplets are punched in by the impact of the surrounding high-speed gas flow. When the centers of droplets are punched through, they become “crowns”-circlets of liquid that themselves break up into rings of subdroplets. These, in turn, may be further broken up, quickly generating enormous surface area for rapid evaporation. This process is so effective in mixture formation that rocket engines with this injector type are strongly resistant to combustion instability.

The higher motorcycle engines rev, the more critical fuel evaporation becomes. Unfortunately, it is difficult to combine high volatility with a high octane number. The harder the fuelblender works to build octane number, the less volatile the fuel becomes-this is true even of pump gas. Sometimes a fuel that evaporates fully but has only a moderate octane number will knock less than a higher-octane fuel that causes leanness by incomplete evaporation. Can you say “compromise”?