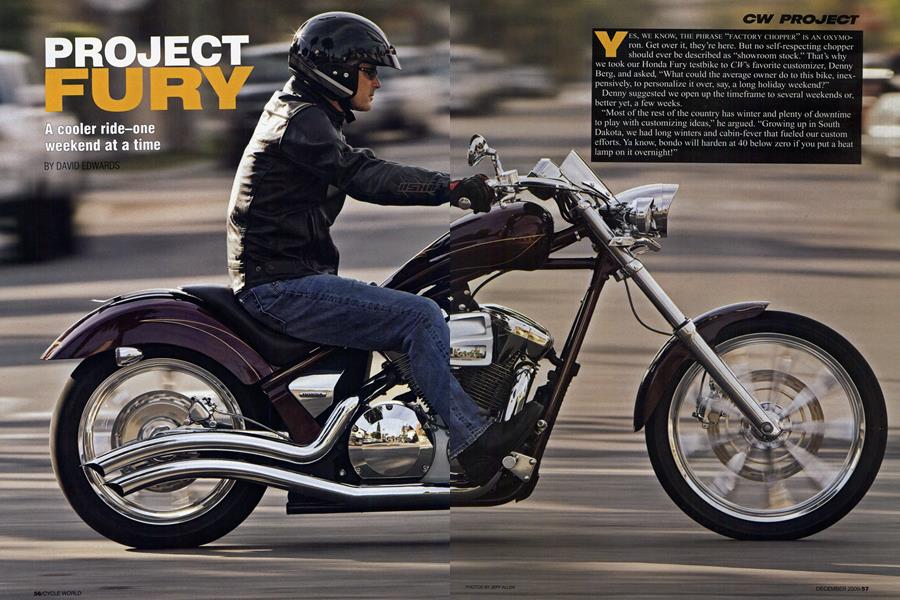

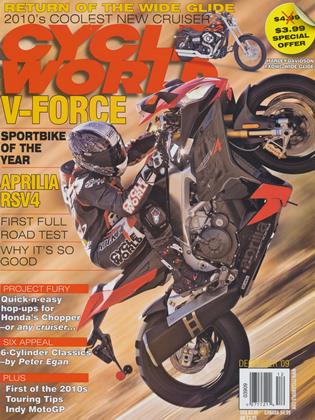

PROJECT FURY

A cooler ride-one weekend at a time

DAVID EDWARDS

CW PROJECT

YES, WE KNOW, THE PHRASE “FACTORY CHOPPER” IS AN OXYMOron. Get over it, they’re here. But no self-respecting chopper should ever be described as “showroom stock.” That’s why we took our Honda Fury testbike to CW's favorite customizer, Denny Berg, and asked, “What could the average owner do to this bike, inexpensively, to personalize it over, say, a long holiday weekend?”

Denny suggested we open up the timeframe to several weekends or, better yet, a few weeks.

“Most of the rest of the country has winter and plenty of downtime to play with customizing ideas,” he argued. “Growing up in South

Dakota, we had long winters and cabin-fever that fueled our custom efforts. Ya know, bondo will harden at 40 below zero if you put a heat lamp on it overnight!”

cycleworld.com/denny BERG'S BEST BIKES

No danger of plunging mercury at Berg’s Palm Springs shop, but there would be no body filler on Project Fury, anyway. The build brief specified anything done to the bike be accomplished with ordinary hand tools a reasonably well-stocked home garage might have.

“The first thing I did was remove the DOT-mandated fork and fender reflectors,” says Denny. “Not PC,

I know, but two small reflectors on the side of your bike are not gonna stop an idiot from T-boning you at an intersection; sorry, it’s true. Next, I removed the warning stickers from the swingarm, frame and tank. There’s an owner’s manual under the seat for that kind of information.”

Lighting was next on the to-do list, starting with the taillight and sub-fender. Berg removed the whole assembly along with the stock turnsignals, replacing the latter with a pair of Deuce dual-filament units from Drag Specialties ($98, www.dmgspecialties. com). He then plumbed Drag’s blackbox ($70) into the wiring loom, turning the LED blinkers into brakelights, á la the Harley Wide Glide tested elsewhere in this issue.

“Next, I offed the amber front signals and installed two tiny but very bright Mini Cat-Eyes ($60), also from Drag’s catalog,” says Berg.

Our plan all along had been to polish the bike’s aluminum bits, but before removing the fork sliders, swingarm, brake calipers, rotors, controls and wheels, Denny had to perform some minor surgery; the Fury’s plastic mini tail-dragger front fender had to be trimmed.

“I took masking tape and experimented with shapes; I wanted to shorten the front and reshape the back to match the rear fender,” says Berg. “When it all looked right, I removed the fender, cut the shape, then smoothed the edges with sandpaper. Remembering that we don’t want to repaint any parts, I’m careful not to scratch the stock paint. After I got the shape right, I went to the hardware store and picked up some Krylon Burgandy rattle-can paint and carefully sprayed the black plastic edges that I just sanded. There ya go, new front fender shape and nobody can tell it’s a chop-job!”

Next, Berg stripped the Fury to get to the aluminum parts. Hiding behind body-color paint, the swingarm is aluminum, a nice surprise, so it got a coat of Zip-Strip. All of the stock “polished” parts are coated with a clear sealer, but Zip-Strip takes that right off, too. “I do as much of the prep as I can before the parts go off to my polisher,” says Denny. “I used to do all of the polishing myself when I was younger, but I’ve gotten lazier, and it’s 115 degrees here in Palm Springs in July! With a lot of grinding, sandpaper and elbow grease, a guy could do this at home during those long winter nights.”

The $600 the polisher charges us is money well-spent; the wheels in particular turned out especially well, looking like expensive, gothic-style customs.

While the alloy was getting all shiny, Berg turned his attention to the small details that really set a mildly customized bike apart, be it a cruiser, a standard or a sportbike.

“The stock chrome frame covers below the seat bothered me,” he says. “Too many reflective angles, but I came up with another easy fix. I grab a can of Krylon’s best satin-black off the shelf, tape off the outwardfacing surfaces and spray a couple of coats. It works! The sidecovers don’t reflect the backside of the pipes or any engine parts. I’m happy and move on.”

To the sidestand, factory chromed but without first being polished. “Rough casting marks don’t look any better by chroming them, a cost factor, I guess,” says Berg. “So I unbolt it and send it off to the chromer’s for polish and plating. This is the only part that I rechrome.”

The stock rear-brakelight switch catches Denny’s ire, too. “It’s a mechanical switch that sticks out behind the front headpipe.

I removed it, cut off the mounting bracket and replace it with a banjobolt switch from Drag ($20). I also replaced the stock brake hoses with precut braided stainless-steel hoses, banjo bolts and hose ends ($169) from Drag Specialties.”

Then he goes after the cables-more precisely, their routing: “Those stock plastic cable guides are nice but they gotta go. I used some polished billet cable clamps from my buddies over at Joker Machine ($40 per five-pack, www. jokermachine.com). I carefully grind the stock clamp-mount pins from the frame and handlebars, drill and tap for the Joker Allen screws and mount ’em up. I had to spread some of the clamps to match the metric frame tubes, but this can be done with a plastic mallet.” Denny’s assessment of Project Fury after it all went back together?

“I think we did what we set out to do,” he says. “A custom bike just about anybody with some mechanical ability, patience and time could do at home.” O

View Full Issue

View Full Issue