Beating heat

TDC

Kevin Cameron

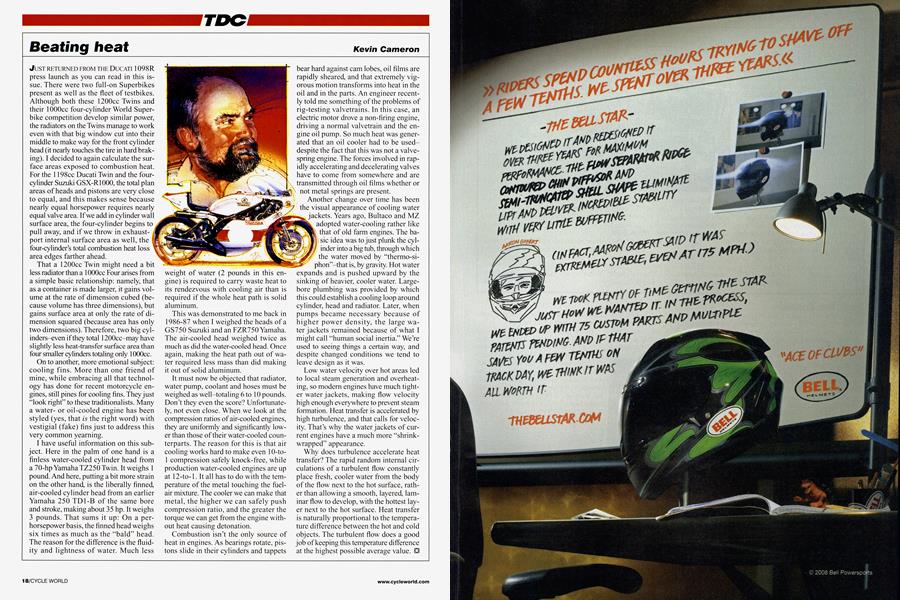

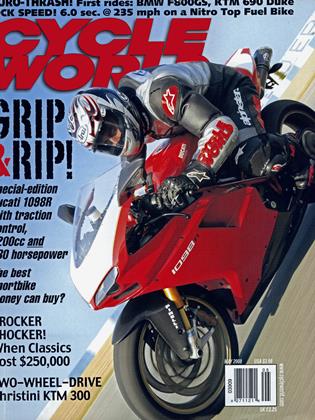

JUST RETURNED FROM THE DUCATI 1098R press launch as you can read in this issue. There were two full-on Superbikes present as well as the fleet of testbikes. Although both these 1200cc Twins and their 1000cc four-cylinder World Superbike competition develop similar power, the radiators on the Twins manage to work even with that big window cut into their middle to make way for the front cylinder head (it nearly touches the tire in hard braking). I decided to again calculate the surface areas exposed to combustion heat. For the 1198cc Ducati Twin and the fourcylinder Suzuki GSX-R1000, the total plan areas of heads and pistons are very close to equal, and this makes sense because nearly equal horsepower requires nearly equal valve area. If we add in cylinder wall surface area, the four-cylinder begins to pull away, and if we throw in exhaustport internal surface area as well, the four-cylinder’s total combustion heat loss area edges farther ahead.

That a 1200cc Twin might need a bit less radiator than a 1000cc Four arises from a simple basic relationship: namely, that as a container is made larger, it gains volume at the rate of dimension cubed (because volume has three dimensions), but gains surface area at only the rate of dimension squared (because area has only two dimensions). Therefore, two big cylinders-even if they total 1200cc-may have slightly less heat-transfer surface area than four smaller cylinders totaling only 1 OOOcc.

On to another, more emotional subject: cooling fins. More than one friend of mine, while embracing all that technology has done for recent motorcycle engines, still pines for cooling fins. They just “look right” to these traditionalists. Many a wateror oil-cooled engine has been styled (yes, that is the right word) with vestigial (fake) fins just to address this very common yearning.

I have useful information on this subject. Here in the palm of one hand is a finless water-cooled cylinder head from a 70-hp Yamaha TZ250 Twin. It weighs 1 pound. And here, putting a bit more strain on the other hand, is the liberally finned, air-cooled cylinder head from an earlier Yamaha 250 TD1-B of the same bore and stroke, making about 35 hp. It weighs 3 pounds. That sums it up: On a perhorsepower basis, the finned head weighs six times as much as the “bald” head. The reason for the difference is the fluidity and lightness of water. Much less weight of water (2 pounds in this engine) is required to carry waste heat to its rendezvous with cooling air than is required if the whole heat path is solid aluminum.

This was demonstrated to me back in 1986-87 when I weighed the heads of a GS750 Suzuki and an FZR750 Yamaha. The air-cooled head weighed twice as much as did the water-cooled head. Once again, making the heat path out of water required less mass than did making it out of solid aluminum.

It must now be objected that radiator, water pump, coolant and hoses must be weighed as well-totaling 6 to 10 pounds. Don’t they even the score? Unfortunately, not even close. When we look at the compression ratios of air-cooled engines, they are uniformly and significantly lower than those of their water-cooled counterparts. The reason for this is that air cooling works hard to make even 10-to1 compression safely knock-free, while production water-cooled engines are up at 12-to-1. It all has to do with the temperature of the metal touching the fuelair mixture. The cooler we can make that metal, the higher we can safely push compression ratio, and the greater the torque we can get from the engine without heat causing detonation.

Combustion isn’t the only source of heat in engines. As bearings rotate, pistons slide in their cylinders and tappets bear hard against cam lobes, oil films are rapidly sheared, and that extremely vigorous motion transforms into heat in the oil and in the parts. An engineer recently told me something of the problems of rig-testing valvetrains. In this case, an electric motor drove a non-firing engine, driving a normal valvetrain and the engine oil pump. So much heat was generated that an oil cooler had to be useddespite the fact that this was not a valvespring engine. The forces involved in rapidly accelerating and decelerating valves have to come from somewhere and are transmitted through oil films whether or not metal springs are present.

Another change over time has been the visual appearance of cooling water jackets. Years ago, Bultaco and MZ adopted water-cooling rather like that of old farm engines. The ba; sic idea was to just plunk the cylinder into a big tub, through which the water moved by “thermo-siphon”-that is, by gravity. Hot water expands and is pushed upward by the sinking of heavier, cooler water. Largebore plumbing was provided by which this could establish a cooling loop around cylinder, head and radiator. Later, when pumps became necessary because of higher power density, the large water jackets remained because of what I might call “human social inertia.” We’re used to seeing things a certain way, and despite changed conditions we tend to leave design as it was.

Low water velocity over hot areas led to local steam generation and overheating, so modern engines have much tighter water jackets, making flow velocity high enough everywhere to prevent steam formation. Heat transfer is accelerated by high turbulence, and that calls for velocity. That’s why the water jackets of current engines have a much more “shrinkwrapped” appearance.

Why does turbulence accelerate heat transfer? The rapid random internal circulations of a turbulent flow constantly place fresh, cooler water from the body of the flow next to the hot surface, rather than allowing a smooth, layered, laminar flow to develop, with the hottest layer next to the hot surface. Heat transfer is naturally proportional to the temperature difference between the hot and cold objects. The turbulent flow does a good job of keeping this temperature difference at the highest possible average value.