Controlled motions

TDC

Kevin Cameron

As I PERFORMED THE PRESCRIBED MOtions on the Nautilus machines, I was careful to prevent the weight stack, rising and falling, from striking the unused weights below it. Exercise is boring, I thought. And then I thought of engine valves, opening and closing like the weight stack, and likewise having to be prevented from actually striking their seats.

When the accident does happen, and my weight stack loudly hits bottom, fellow fitness-seekers look around with mildly pleased expressions on their faces, as if to say, “Thank goodness there’s someone here who’s even worse at this than lam!”

Valves cannot be allowed to seat at more than a very few feet per second, despite the fact that the cam hurls them upward at more than a thousand g’s of acceleration, leaving to the valve spring the job of decelerating fast-moving valves in strict conformity with the contour of the cam lobe. Over the top of the lobe, the valve is essentially motionless, after which the spring must accelerate it back toward its seat as the cam rotates into its closing flank. In the last few degrees before the seat, the cam profile slows the valve with the mirror image of its previous acceleration upward, setting it down gently. Just as with the Nautilus machine, gentle landings permit durability over millions of open/close cycles.

This explains why valve-clearance adjustments are a necessity. If clearance becomes too small (perhaps from valve cupping or seat recession) the valve may eventually stand slightly open when it should be closed. The resulting leakage will reduce power or, if it is an exhaust valve, the outrush of peak temperature combustion gas will bum the valve’s face, shortly making it look as if it had been attacked with a cutting torch. If the clearance becomes too large, the necessarily gentle initial opening and final closing contours of the cam lobe will become hidden and inoperative in that increased clearance. Violent impact takes their place. As some operators of the new four-stroke MX engines have discovered, the resulting valve-seat pounding quickly becomes a $3500 engine wreck. The loosened seat holds the valve open when it should be closed, and the piston hits it and is broken in the process. As matters quickly go from catastrophic to worse, the crank, cylinder and crankcase are wrecked in the process of absorbing all the considerable kinetic energy in a fast-spinning crankshaft. All we hear is a brief crunch.

The key to mechanical durability in engines is that although many of the motions of parts are rapid and their accelerations may be extreme, impacts are (normally) completely avoided. As a piston decelerates rapidly on its approach to TDC, it may experience several thousand g’s, but the build-up to this peak and the decrease to zero that quickly follows are perfectly smooth and continuous. The resulting loads in connecting rods can be worked out, and enough material provided in them to make such loads perfectly tolerable.

It’s not always so smooth. To generate the mixture turbulence necessary for fast combustion, piston crowns are configured with squish areas-regions that come very close to the head at TDC. A typical figure for squish clearance is .025-inch. In such tight squish regions, very little carbon forms because with crank deflection and con-rod stretch at higher revs, the piston nearly touches. And so it happens that not very much has to go wrong to make it touch in a big way. In twostrokes, a failing con-rod big-end bearing is the usual cause. Occasionally the rider will catch one of these failures just as it happens and you can see some of its effects. The top ring land is hammered down by hitting the head, which locks the piston ring in place. The piston cracks or bends. The head takes a whacking. Nothing much useful is left afterward but souvenirs. Metals don’t like impact!

When people began to build gears to transmit serious power, they found that gear teeth bend enough to cause problems. When the pair of teeth carrying most of the load at the moment bends, they allow their respective gear wheels to rotate slightly farther than the drawing says they can. This brings the following pair of teeth into earlier and therefore harder-than-normal contact, causing scuffing and possible failure. To prevent this, modified tooth contours are made which are “eased off” in the engagement area to prevent this scuffing that arises from tooth bending. In this case, the scuffing was the gears’ way of telling their designer to remove material in that area.

Camshaft drives are a fertile garden of unplanned motions.

; Anyone who has turned an engine on the bench with a T-bar has felt the lumpy resistance of camshafts. Complicating the problem of driving this lumpy load is the farfrom-regular rotation of crankshafts. No matter how much flywheel mass we add, crankshafts always speed up when a cylinder fires and slow down between firings. The more acceleration we want from our vehicle, the harder we work to remove flywheel mass, and the greater the speed variation of the lightened crank. Both the cam(s) and crank are torsionally and longitudinally bendy, so as the cam resists rotation in its lumpy way and the crank’s instantaneous speed varies, lots of unplanned twisting, bending and knocking can appear-often enough in brand-new designs to break gears, chains, toothbelts or tensioners. Every engine designer has a bag of tricks by which to attack this problem-and the occasional development program has even been stopped cold by the expense of finding a solution.

In 1992, when two-stroke 500cc GP engines were given traction-boosting close firing order (firing all four cylinders within 70-90 degrees, letting tire grip recover for the remaining 3A of a revolution), lots of teams had to resort to changing primary gears every day. Otherwise they broke unpredictably from the higher peak torque loadings. The parts that have been removed in such programs look perfect-but their stress history makes them untrustworthy. The more cyclic loads resemble impacts, the more metal resents it. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontElectric Chair

February 2008 By David Edwards -

Leanings

LeaningsThe Road To Harleysville

February 2008 By Peter Egan -

Departments

DepartmentsHotshots

February 2008 -

Roundup

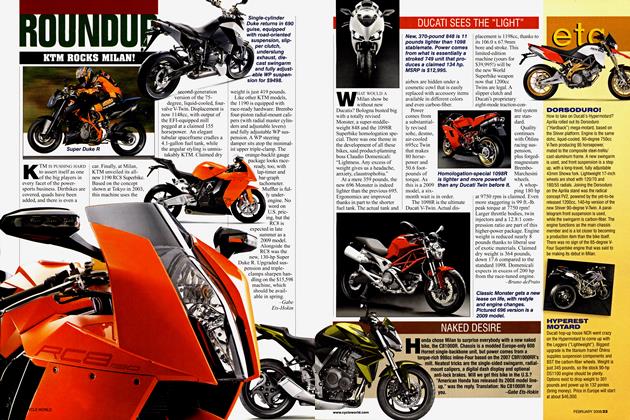

RoundupKtm Rocks Milan!

February 2008 By Gabe Ets-Hokin -

Roundup

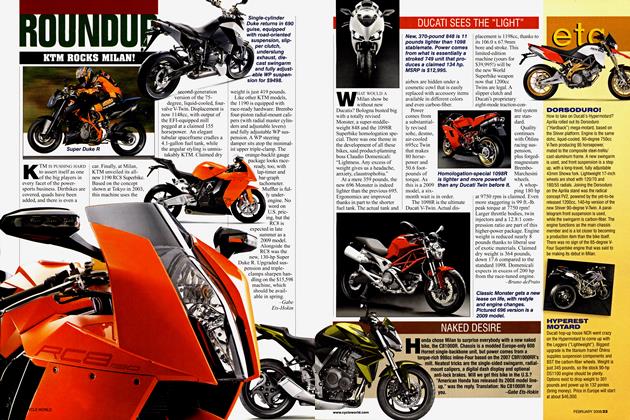

RoundupNaked Desire

February 2008 By Gabe Ets-Hokin -

Roundup

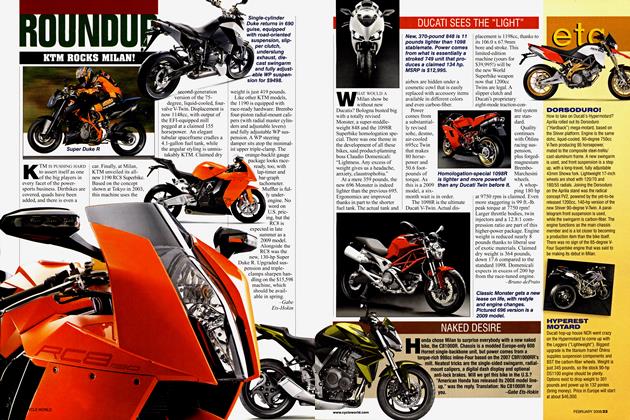

RoundupDucati Sees the "Light"

February 2008 By Bruno Deprato