When solids aren't

TDC

Kevin Cameron

I BENT OVER TO PICK UP THE TEA TRAY and its load of goodies. The pressed-steel tray deflected noticeably as I lifted it at the edges. For an instant I had a direct sense of solids as collections of myriad atoms, all interconnected by tiny springs.

Solids are not rigid, no matter how hard, strong or thick they are. Waves of deformation travel through the Earth’s crust, miles thick. Stand on any bridge carrying traffic and feel the vibration as it deflects from the impact of vehicular wheels hitting its joints. Solids are just collections of massive atoms, connected to each other by the elastic electrical forces generated by their electron arrangements.

Here comes the trash truck, collecting all the season’s colorful wrapping paper. 1 hear it from afar by the groaning of its brakes. This is very old. My three sons and I went to see the Collings Founda tion’s B-17 and B-24 fly a few years ago. | As each aircraft taxied in after landing, its 60-year-old Bendix drum brakes made the very same sound. I think of the friction material, taking a grip on the slowly turning drum. The anchor points of the brake shoes deflect as the shoes begin to rotate with the drum. But atomic bonds stiffen rapidly as they are stretched and their resistance increases, jerking the brake shoes free. As the shoes slide, all those deflected atomic bonds in the shoe anchor points and backing plates snap back, springing the shoes back and forth. Forward motion slows their sliding against the drum enough for the friction material to grip again. A rapid grip/release cycle begins, and I hear it as groaning.

There are other sound sources here, as well. When the shoes grip the drum but cannot rotate very far with it, the drum deforms into an oval. Because atomic bonds are springy, this ovality propagates around the drum as a wave of deformation. As this wave moves the drum away from the hard-gripping leading ends of the brake shoes, the momentary drop in frictional grip contributes to making the shoes slip, and another contribution to the stick-slip cycle chimes in. This suggests why the sound is a groan and not a pure, ringing tone-it is made up of more than one frequency.

I spoke with a 90-year-old aircraft engine engineer who had worked with large radial engines. He remarked that they had measured the deflection of the steel cylinders as the engines fired; they moved .020 of an inch. This required flexible in-

take and exhaust connections if chronic cracking was to be avoided.

As a cylinder fired and its combustion pressure climbed quickly up to 1200 or 1400 psi, the crankshaft was rotating past top center. The farther it rotated, the more the con-rod took up an angle to the cylinder. Meanwhile, the resulting 20,000pound force was compressing the connecting-rod, squeezing oil out of the crankpin bearing at its edges and trying to uproot the now-somewhat-bulging cylinder from the crankcase. Both are deflecting-the cylinder’s bolting flange downward, the crankcase bolt circle upward. Metal doesn’t like to be bent backand-forth like this, so the materials have to be of high quality or they will break.

As the turning crankshaft increases the angle between con-rod and cylinder, a side-force appears. This con-rod sideforce is trying to push the cylinder sideways more and more as rod angularity increases. But there is a limit, for at the same time combustion pressure is falling as the descending piston expands the hot gas above it. Stretched atomic bonds in all the parts regain the upper hand as the applied combustion pressures die away. Cylinder and crankcase flanges snap back, and the 45-pound cylinder as a whole swings back in the opposite direction.

Although it would appear that engines

with cast, one-piece cylinder blocks might be immune to such deformations, they are not. Engines bend and twist because all the above forces are acting invisibly within them. High rpm, with its tremendous inertia forces, causes whole cylinder block/crankcase assemblies to deflect at least as much as the above. In the radial aircraft engines of 50 and 60 years ago, both the crankcase and the cylinders were forged as the best way to make them both light enough to fly and fatigue-resistant enough to survive.

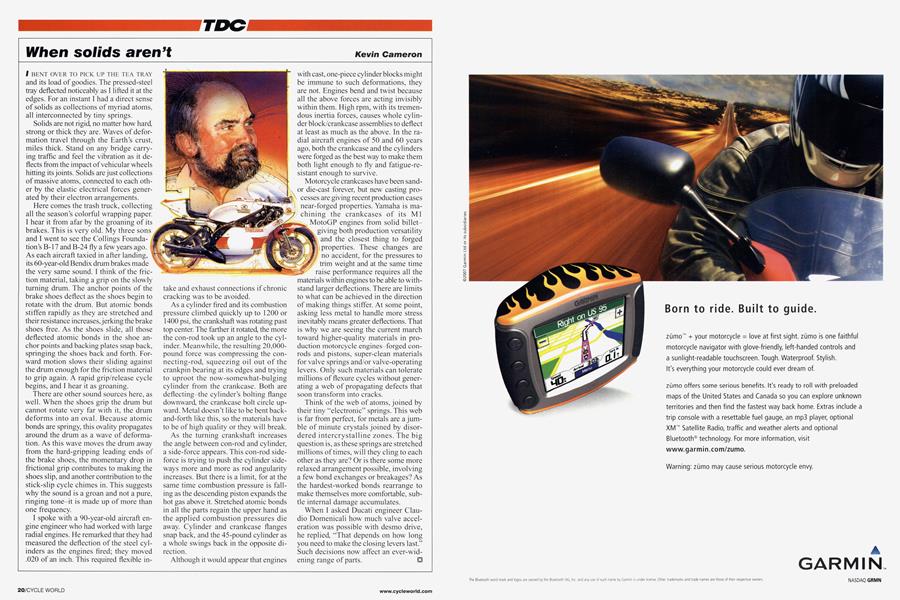

Motorcycle crankcases have been sandor die-cast forever, but new casting processes are giving recent production cases near-forged properties. Yamaha is machining the crankcases of its Ml MotoGP engines from solid billetgiving both production versatility and the closest thing to forged ¡¡properties. These changes are no accident, for the pressures to trim weight and at the same time raise performance requires all the materials within engines to be able to withstand larger deflections. There are limits to what can be achieved in the direction of making things stiffer. At some point, asking less metal to handle more stress inevitably means greater deflections. That is why we are seeing the current march toward higher-quality materials in production motorcycle engines-forged conrods and pistons, super-clean materials for valve springs and/or valve-operating levers. Only such materials can tolerate millions of flexure cycles without generating a web of propagating defects that soon transform into cracks.

Think of the web of atoms, joined by their tiny “electronic” springs. This web is far from perfect, for metals are a jumble of minute crystals joined by disordered intercrystalline zones. The big question is, as these springs are stretched millions of times, will they cling to each other as they are? Or is there some more relaxed arrangement possible, involving a few bond exchanges or breakages? As the hardest-worked bonds rearrange to make themselves more comfortable, subtle internal damage accumulates.

When I asked Ducati engineer Claudio Domenicali how much valve acceleration was possible with desmo drive, he replied, “That depends on how long you need to make the closing levers last.” Such decisions now affect an ever-widening range of parts. □