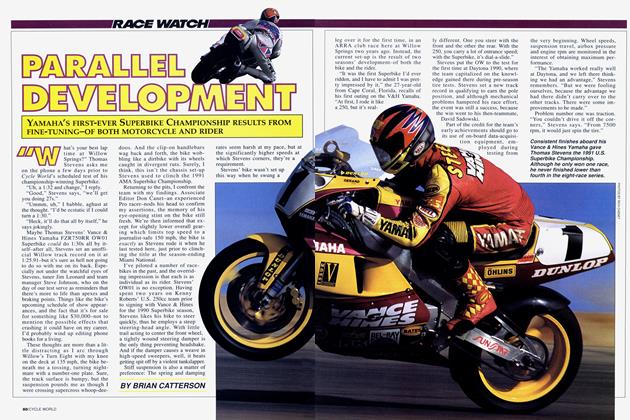

FORGING A FUTURE

Michael Czysz has a plan, capable personnel and funding. Does he have a chance in hell?

RACE WATCH

KEVIN CAMERON

SOME SUGGEST THAT ONLY LARGE COMPAnies can innovate because only they can afford original research and the development that exploits it. Others claim only small companies can innovate because of their agility and tolerance for the creative personalities who sicken in large organizations. It's also trendy to say, "genius ships product." The latter view observes that ideas are plentiful, but genius is their translation into accounts receivable.

Three years ago I went to Portland, Oregon, to see what Michael Czysz was up to. He runs a suc-

cessful interior and conceptual building design firm (see his work in Las Vegas) and is an enthusiastic amateur motorcycle racer.

He also has strongly held ideas about motorcycle design and has succeeded in finding $20 million in start-up capital to build novel machines. That has enabled specialists to be hired away from Cosworth, Ducati and Kenny Roberts’ GP Motorsports to translate those ideas into metal. I felt three years ago that he had a reasonable mix of promising and not-so-promising ideas for street and/or racing motorcycles of radical design.

Two years later I feared the public side of his work shared too much with past Indian revivalstoo much drum, not enough melody. Now I’ve returned from another trip to Portland. In brightly lit premises I met the new staff and saw them at work with modern modeling and CAD software, about to cut metal in a shop full of

new equipment. I saw the initial main casting for an engine of original design and many rapid-prototyped plastic parts-engine and chassisin full scale. I saw a dedicated dyno room containing new units, plumbed and connected, ready for business. Great things could be accomplished in this dream shop, which is similar to facilities I saw at Roberts’ place in England. Just getting this far is a serious accomplishment.

Here is what they are up to.

The machine you have seen in magazines and videos is a trial-of-concept test mule, powered by an engine made from reworked Suzuki parts. It does, however, embody many of the ideas that will be carried forward into the next machine, whose powerplant is designed by the new professional staff.

The engine appears at first to be an inline-Four, oriented the long way in the chassis. Then you see that it’s split in the middle-two 180-degree parallel-Twins, rotating in opposite directions. In the test mule, this was accomplished by placing gears on the inner end of each twin crank, then raising the front “half engine” to enable the two gears to mesh. Because it would be difficult to machine stepped crank-bearing bores and insufficiently strong to fasten cases together as they are in the mule, the new engine is different. All its crank-bearing bores are in line, and the central gears mesh not with each other but with gears located on the axis of a jackshaft running alongside the cranks. One of these connects through an idler, thus allowing its crank to turn opposite to the other as both cranks drive the shaft.

What does this accomplish? Instead of presenting the engine’s broadest profile to the wind, it presents its slimmest. The goal is not the cancellation of engine gyro effect; Yamaha and Suzuki also had twin contra-rotating cranks in their two-stroke 500cc GP engines. Instead, the purpose is to permit lengthwise mounting without disturbance from crank inertia.

Clutch and transmission axes parallel the crank, with final drive turning 90 degrees via angle gearing, passing to the rear wheel by conventional chain drive.

Front suspension is by a single spring

damper unit integrated into the steering head, rather than by separate dampers and springs in each fork leg. While current sportbikes and MotoGP designs provide supplementary in-comer front lateral suspension by allowing steering head and

forward chassis to flex sideways, Czysz commendably moves the flexure closer to the tire. The lower legs of his fork are oval, giving large twist and braking stiffness combined with enhanced lateral flexibility.

To ensure supple fork action both under heavy braking and during acceleration when tire load is light, the fork sliders move on linear roller bearings rather than on the usual lubricated Rulon bushings. The sensitive feel that results is a best-liked feature among those who have ridden the bike.

In the words of the song, “An’ if that ain’t enough to make you flip your lid, there’s one more thing..the lower fork crown attaches to the stem via a pivot that allows the legs to tilt slightly from side to side in response to mid-corner bumps. That motion is opposed by a compliant link between the top crown and the top of the stem. The stiffness of this link can be-and has been-varied, and a damping medium can be included if that is found desirable.

The engine presents other interesting features. Its bore/stroke ratio of 1.75:1 is beyond the 1.5 usual found in modern-day sportbikes yet short of the higher ratios that lead to Formula One’s cramped combustion chambers and sluggish flame speeds. At the 7500g peak piston acceleration now accepted in sportbike engines, that yields peak revs of 15,000. Given combustion pressure usual in early development, that becomes just over 200 horsepower, which is comparable with what is claimed for lOOOcc Fours in World Superbike. The engine has four valves per cylinder set at an included angle of 21 degrees and driven by conventional inverted-bucket tappets.

To continue the theme of reduced frontal area, the engine could not have its intake system project to the sides in conventional fashion. Therefore, Czysz resorted to some trickery. Cylinders 1 and 3 are angled slightly one way from the engine’s central plane, while cylinders 2 and 4 angle the other way. This permits the intakes (two per side) to be folded in against the engine to minimize their contribution to width. It also places all four intake bells within an airbox of reasonable dimensions. This angling of the cylinders also offers the option of a staggered “big-bang” firing order.

With this narrow-angle V-Four layout, three camshafts are necessary. The center (intake) cam and one side (exhaust) cam are driven by spur gear train from the rear of the engine, while the second exhaust cam is driven by gear from the front of the center cam. Engine intakes are fitted to pass down between intake and exhaust cams on both sides, making the result quite narrow. If necessary for drive stability in the racing application, a Cosworth-style compliant drive element can be built into the cam gear train.

Oiling is by end feed of the cranks in F-1 style, from what is at the moment a wet sump. If the engine is raced and requires it, this may become four separate dry sump crankcases (again,

F-l style, to eliminate cylinder-to-cylinder air-pumping loss), each with its own scavenge pump. The water pump is to be electrically driven, allowing its speed to be matched to actual need and saving some power.

Familiar geometry prevails at the rear of the machine, allowing squat/anti-squat suspension forces to be conventionally adjusted by changes to swingarm pivot height. This supersedes an earlier version with concentric front sprocket and swingarm pivot.

To provide supplementary rear suspension at high lean angles, swingarm beams are compliant laterally but stiff vertically as seen in conventional racing machines

of the past five years. Czysz calls his focus on such lateral compliance “2D suspension.” This gives a name to the need that appeared so dramatically 13 years ago when Wayne Rainey’s super-stiff Yamaha YZR500 failed to hook up in corners in the first GP of 1993. It was then clear that future motorcycles would need two suspension systems: the conventional vertical one of dampers and springs, plus a new lateral one, currently of engineered flexibilities, at right angles to it.

To avoid the width and drag of a typical “square-rigger” radiator (in conventional bikes, it is the full width of the fairing), the Czysz machine has two narrower rads-a front and a rear.

Start-up capital has provided a spacious, well-lit design office equipped with the usual computers running a wide range of Ricardo design software. Next door, a machine shop stands ready to cut metal with Haas machining and turning centers, a surface grinder and other tooling. Adjacent are engine and chassis assembly areas and a 3D shape-development shop centered on a giant CAM router. A dyno room contains a new Superflow 902 engine dyno and also a chassis unit. At the time of my visit, some machined parts had begun to arrive from suppliers. Pistons, cranks and rods will be sourced from Cosworth.

In the design office stood the first main engine casting, produced in a mold generated directly by a computer-driven, sandlayer deposition process akin to that of rapid prototyping. This potentially allows delivery of a metal casting as little as one week after receipt of the computer file. The four canted cylinders and the head are made in one piece, eliminating not only the sealing problems of a head gasket but also the distortion and weight associated with conventional bolt retention of a separate head. Valve seat machining can be carried out with straight-on tooling through the cylinders, thanks to the short stroke and narrow valve angle. This cylinder/head unit secures to the crankcase by long studs which pass through case and main-bearing girdle.

The prototype phase of engine development is undergoing important changes thanks to short casting lead time. Instead of preparing 20 or more prototype engines as is normal, evolution of the design can begin from the very first casting, leading to adaptive changes in the second and later castings.

The really fascinating part of my time in Portland was the interplay of Czysz’s conceptual aims and the hardware experience, and factual understanding of powertrain engineers (and Cosworth “graduates”) Simon Jackson and Adrian Hawkins. They said this job caught their attention because it offered a change from the standard implementations that are the usual fare in specialist firms such as Cosworth, Ilmor and Lotus Design. Engineering-race engineering, in particular-is very conservative, favoring refinement of existing architectures over exploration of alternatives.

These engineers say they enjoy the challenge of finding practical ways to implement the novel priorities that Czysz insists upon. Reshaping the engine into a new architecture has required solutions for unusual problems. Who can argue with reduced frontal area or with the idea that sport and racing motorcycles need both conventional and “sideways” suspension? Czysz believes that by shifting his focus away from expensive refinement of the conventional toward identification and solution of neglected problems, he can create a vehicle with abilities unique enough to make a place for itself in the market or on the track. His backers clearly agree. His plan calls not only for early limited production of the machine now in work, and possibly for entry into racing, but also for other production types to follow, including a 600.

Motorcycles have more drag per square foot of frontal area than do cars, because a bike’s wake cannot be closed within its short length. This is part of why a small four-door sedan may achieve better fuel economy than large-engined sportbikes.

Therefore, the obvious strategy for motorcycle drag reduction is to minimize frontal area. Japanese 1 OOOcc sportbikes have measured 21 inches across their fairings, with the classic Ducati 916 sveltest at 19 inches. A year ago, Kawasaki’s ZX10R split the difference at 20 inches. Is this width the fault of the transverse engine? If you transversely line up four big 87mm bores in a row separated by 5mm of metal and add 25mm on one end for a gear cam drive, you get an engine width of just under 16 inches-the hip width of a human and that of the transverse engine in Yamaha’s MotoGP YZR-M1.

At present, the trend of chassis design is to concentrate engine and gearbox mass far forward, loading the front tire to hold line during off-comer acceleration and allowing use of a swingarm 24 or more inches in length. Czysz’s longitudinal engine reverses this trend in hope of a drag reduction from reduced width.

Czysz’s ducted rear radiator is much like that seen on the Saxon Triumph of a few years ago. This can be highly effective because it takes in high-energy air from near the front of the machine, converts that energy into pressure to push air through the radiator core, then discharges the heated air into the low-pressure region behind the machine. Properly executed, a ducted rad is a low-grade jet engine that can combine good cooling with low (or even non-existent) drag.

I very much like Czysz’s devotion to his “2D Suspension” concept, and I believe the rolling-bearing fork may give a useful jab to makers of conventional sliding-bushing forks. Nikko Bakker built a single-sided roller fork some years ago but it was not adopted. Chassis lateral flex was hailed in the late 1990s as a means of improving tire grip in bumpy corners, but today its lack of damping facilitates chatter and “vibration.” Thorough analysis and novel solutions are needed. This is an area in which a modest investment plus effective thinking could produce significant results. I hope to see it.

Unlike some Internet pundits, I am unbothered by the 1-2 percent power loss that occurs in the right-angle drive between Czysz’s engine and front sprocket. Every rear-drive car has exactly this kind of right-angle gearing, and Czysz is in any case not part of a horsepower race.

I’m not easily persuaded by radical projects. Success is expensive and it seldom happens by accident. Ducati estimated its price of admission to MotoGP at $32 million-and it already had established design and development groups, prototype shops and long rows of dyno cells. Conversion of ideas into performance requires testing. Cam drives develop parasitic oscillations. Oil defies gravity. Torsional vibrations not found on the dropdown menus devour shafts and gears. Recursive testing and redesign settle such issues, but their costs can be punishing. This is where the majors shine. Their resources and experience trample such problems to death. Therefore, what Michael Czysz proposes is ambitious. Aprilia, with experienced racing personnel and 18 race department dyno cells, failed in MotoGP despite a powerful F-l-based engine and wind-tunnel studies. Ducati, dominating World Superbike for years, has won only four MotoGP races.

Czysz must not compete with the majors at their own game, as Aprilia did. As the late rider/engineer AÍ Gunter told Dick Mann years ago, “You can’t beat your competitors using their methods. They had them first and will always be ahead of you. You have to find something new that’s yours alone.” I hope Czysz will spend wisely on crucial issues like lateral suspension, whose solutions may maximally improve performance at minimum investment. That is his wager-that carefully targeted development can raise the game significantly. We await the product. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontPassages

August 2006 By David Edwards -

Leanings

LeaningsBeasts of Burden

August 2006 By Peter Egan -

TDC

TDCThe Why's of Efi

August 2006 By Kevin Cameron -

Departments

DepartmentsHotshots

August 2006 -

Roundup

RoundupOf Crossbreeds And Concept Hybrids

August 2006 By Mark Hoyer -

Roundup

RoundupCrf45o Revision Decision

August 2006 By Ryan Dudek