Untying knots

TDC

Kevin Cameron

A FRIEND RECENTLY SENT ME A CD stuffed with scans of documents from the National Archives on radial air-cooled engine development. They cover work done in 1920-26 at the U.S. Army’s former air development center in Dayton, Ohio. Day after day, single-cylinder test engines ran full throttle until they failed. When they did, crews stripped them apart, engineers analyzed the blitzed pieces, and improved parts were designed and built. As you’d expect, a vast amount of information was generated in the process. Reading these records is fascinating to me because it shows how far human knowledge has come, and how useful information emerges gradually from apparent chaos.

A striking fact about engine technology in this period is how entangled all engine variables were-it was hard to push forward in any one area without compromising what had already been accomplished in some other area. Identifying the important variables and disentangling them from one another was a painstaking process.

A radial engine has one master connecting rod with several link rods attached around the outside of its big-end bearing-one for each cylinder, like the petals of a flower. With seven or nine cylinders loading a single big-end bearing, provision of adequate lubrication was difficult. Yet if that bearing was given all the oil flow it needed, so much oil was thrown radially out into the cylinders that the oilcontrol rings on the pistons were swamped and the plugs fouled. Therefore that bigend bearing was given barely enough oil to survive. Because pistons are lubricated by oil flung from rod bearings, this reduced oil flow led to scuffed pistons. Mechanics scanned the cylinders during testing for any indication that one was turning blue with heat.

Plugs foul when the fuel-air mixture is too rich. The extra fuel liberates carbon that deposits on plugs as a conductive film, shorting out the spark. But if these engines were jetted down enough to keep the plugs clean, they ran too hot. When that happened, what little oil there was on cylinder walls boiled away, causing scuffing. Hot cylinder walls mean hot pistons. Hot pistons heat the fuel-air mixture entering the cylinder, roasting it toward the temperature at which it will detonate. Many tests ended in detonation and piston damage. Testers watched the exhaust for puffs of black smoke and sparks, indicating detonation. The easy way to cool the engine enough for survival was to lower flame temperature by running rich-rich enough to foul plugs. How about hotter plugs to stop the fouling? Sorry, hotter plugs were yet another path to immediate detonation.

Why not improve the oil-control rings on the piston enough to keep extra oil out of the combustion chambers, letting sparkplugs bum clean? Sorry, if they put ventilated two-rail automotive-style scraper rings in those hot-running cylinders they wore out in a couple of hours. The practical answer was taper-faced rings that scraped oil down and rode up on the oil on the upstrokes. Multiple scrapers? Every extra ring, then and now, eats power. Pick your poison.

The engine bellows on the dyno, but after a few hours the torque falls off. They shut down, then found metal on the oil screens. The engine was pulled off the stand and wheeled away to disassembly. Many valve springs broken. The desperation over valve springs was so great in that time that one solution seriously considered was the “cluster spring,” a group of as many as 12 small springs, arranged in a circle around each valve. The attraction? A single failure couldn’t cause an engine wreck. But they broke by the dozen. In our own time, F-l engineers were driven to distraction by breakage of even the finest of metal springs. So Renault invented pneumatic springs.

Progress was steady. Electric furnace steel for springs. More cooling-fin area. Better oil control. Wider sparkplug heat range. Improved bolts and studs with smooth, organic shapes in place of sharp comers. Reduced head cracking from hundreds of alloy tests. Increased oil circulation pulled temperatures of internal parts down, extending their lives. Standards were determined for crankshaft design, resistant to fatigue failure. Stroboscopes revealed the real, as opposed to apparent, motions of parts. Pushrods half an inch apart somehow touched each other. Cylinder mounting flanges and the bolts holding them onto crankcases were seen to “walk” and bend continuously, explaining the fret marks that always appeared where the cylini ders bore against the case. Nothing is rigid. Everything flexes. Spectacular things happened. A cylinder blew off the case and into the prop, pieces of crankcase still bolted to it. On another head, valve seat counterbores had sharp comers. Ma Nature hates sharp comers. Cracks started at the comers, A few hours later the top of the head blew off, valves and all.

Bushings in rocker arms seized, forcing tests of many new materials. A few worked. Valves and rockers fractured from too-vigorous cam profiles. Little by little, the “book” on how to make successful engines grew thicker. When it came to parts under heavy stress, nature just plain disliked some shapes. Pistons with stiffening ribs under their domes? Nope, they acted like jacks, pushing the sides of the piston out against the cylinder walls, producing seizures. Super-light pistons? Rejected. Thin piston domes provided an inadequate conduction path for combustion heat. They overheated, softened and were blown into the crankcase.

Sometimes the problems piled up and nothing worked. Then they would drain and refill the test engine’s oil system with accident-forgiving castor oil, riehen up the carburetors and start over.

We have some new tools today-computers and software to model many aspects of engine design. They save time and eliminate certain kinds of errors, but the work hasn’t changed that much. Even the best designs still require testing to destruction. And there are still surprises.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontWorld's Fastest Indian

February 2006 By David Edwards -

Leanings

LeaningsBeemer Report Card, Summer Semester

February 2006 By Peter Egan -

Departments

DepartmentsHotshots

February 2006 -

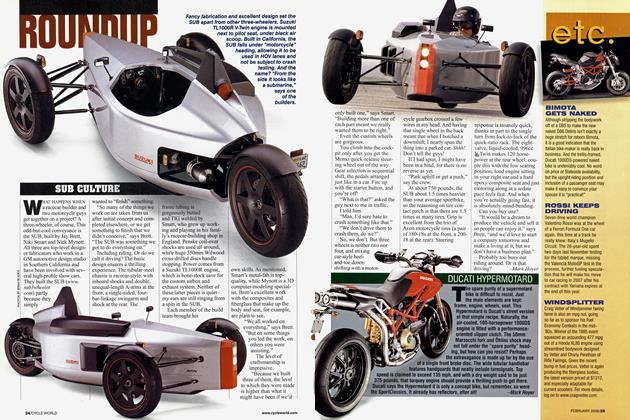

Roundup

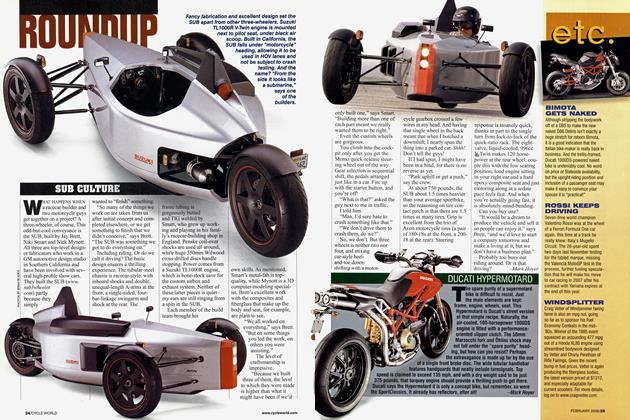

RoundupSub Culture

February 2006 By Mark Hoyer -

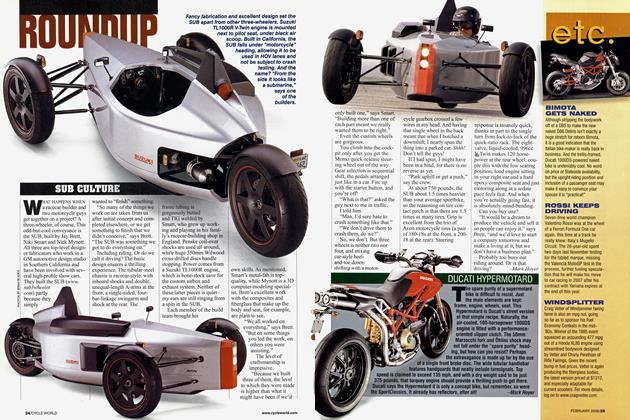

Roundup

RoundupDucati Hypermotard

February 2006 By Mark Hoyer -

Roundup

RoundupEtc.

February 2006