Little things

Kevin Cameron

TDC

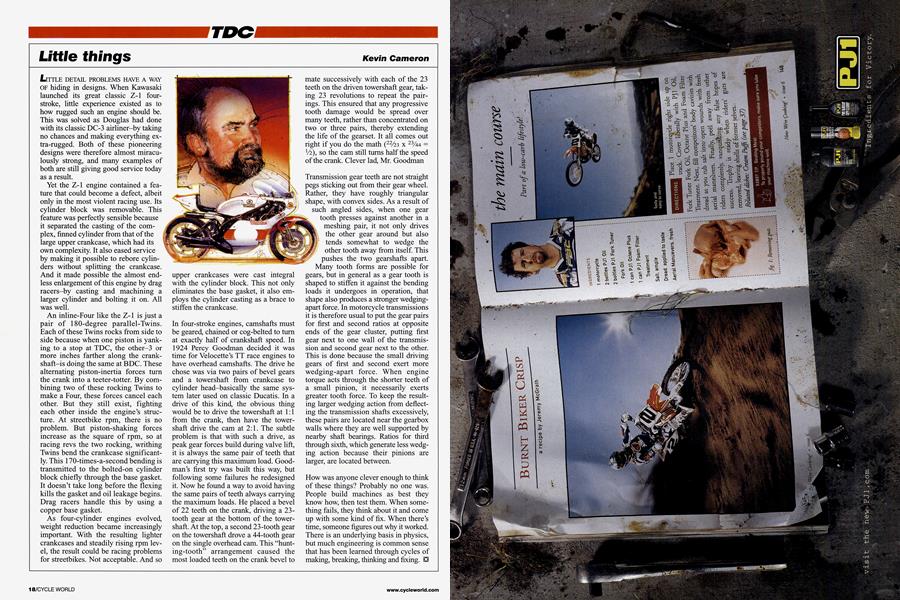

LITTLE DETAIL PROBLEMS HAVE A WAY OF hiding in designs. When Kawasaki launched its great classic Z-l fourstroke, little experience existed as to how rugged such an engine should be. This was solved as Douglas had done with its classic DC-3 airliner-by taking no chances and making everything extra-rugged. Both of these pioneering designs were therefore almost miraculously strong, and many examples of both are still giving good service today as a result.

Yet the Z-l engine contained a feature that could become a defect, albeit only in the most violent racing use. Its cylinder block was removable. This feature was perfectly sensible because it separated the casting of the complex, finned cylinder from that of the large upper crankcase, which had its own complexity. It also eased service by making it possible to rebore cylinders without splitting the crankcase. And it made possible the almost endless enlargement of this engine by drag racers-by casting and machining a larger cylinder and bolting it on. All was well.

An inline-Four like the Z-l is just a pair of 180-degree parallel-Twins. Each of these Twins rocks from side to side because when one piston is yanking to a stop at TDC, the other-3 or more inches farther along the crankshaft-is doing the same at BDC. These alternating piston-inertia forces turn the crank into a teeter-totter. By combining two of these rocking Twins to make a Four, these forces cancel each other. But they still exist, fighting each other inside the engine’s structure. At streetbike rpm, there is no problem. But piston-shaking forces increase as the square of rpm, so at racing revs the two rocking, writhing Twins bend the crankcase significantly. This 170-times-a-second bending is transmitted to the bolted-on cylinder block chiefly through the base gasket. It doesn’t take long before the flexing kills the gasket and oil leakage begins. Drag racers handle this by using a copper base gasket.

As four-cylinder engines evolved, weight reduction became increasingly important. With the resulting lighter crankcases and steadily rising rpm level, the result could be racing problems for streetbikes. Not acceptable. And so

upper crankcases were cast integral with the cylinder block. This not only eliminates the base gasket, it also employs the cylinder casting as a brace to stiffen the crankcase.

In four-stroke engines, camshafts must be geared, chained or cog-belted to turn at exactly half of crankshaft speed. In 1924 Percy Goodman decided it was time for Velocette’s TT race engines to have overhead camshafts. The drive he chose was via two pairs of bevel gears and a towershaft from crankcase to cylinder head-basically the same system later used on classic Ducatis. In a drive of this kind, the obvious thing would be to drive the towershaft at 1:1 from the crank, then have the towershaft drive the cam at 2:1. The subtle problem is that with such a drive, as peak gear forces build during valve lift, it is always the same pair of teeth that are carrying this maximum load. Goodman’s first try was built this way, but following some failures he redesigned it. Now he found a way to avoid having the same pairs of teeth always carrying the maximum loads. He placed a bevel of 22 teeth on the crank, driving a 23tooth gear at the bottom of the towershaft. At the top, a second 23-tooth gear on the towershaft drove a 44-tooth gear on the single overhead cam. This “hunting-tooth” arrangement caused the most loaded teeth on the crank bevel to

mate successively with each of the 23 teeth on the driven towershaft gear, taking 23 revolutions to repeat the pairings. This ensured that any progressive tooth damage would be spread over many teeth, rather than concentrated on two or three pairs, thereby extending the life of the gearset. It all comes out right if you do the math (22/23 x 23/44 = Vi), so the cam still turns half the speed of the crank. Clever lad, Mr. Goodman

Transmission gear teeth are not straight pegs sticking out from their gear wheel. Rather, they have roughly triangular shape, with convex sides. As a result of such angled sides, when one gear tooth presses against another in a meshing pair, it not only drives the other gear around but also tends somewhat to wedge the other tooth away from itself. This pushes the two gearshafts apart. Many tooth forms are possible for gears, but in general as a gear tooth is shaped to stiffen it against the bending loads it undergoes in operation, that shape also produces a stronger wedgingapart force. In motorcycle transmissions it is therefore usual to put the gear pairs for first and second ratios at opposite ends of the gear cluster, putting first gear next to one wall of the transmission and second gear next to the other. This is done because the small driving gears of first and second exert more wedging-apart force. When engine torque acts through the shorter teeth of a small pinion, it necessarily exerts greater tooth force. To keep the resulting larger wedging action from deflecting the transmission shafts excessively, these pairs are located near the gearbox walls where they are well supported by nearby shaft bearings. Ratios for third through sixth, which generate less wedging action because their pinions are larger, are located between.

How was anyone clever enough to think of these things? Probably no one was. People build machines as best they know how, then test them. When something fails, they think about it and come up with some kind of fix. When there’s time, someone figures out why it worked. There is an underlying basis in physics, but much engineering is common sense that has been learned through cycles of making, breaking, thinking and fixing. □