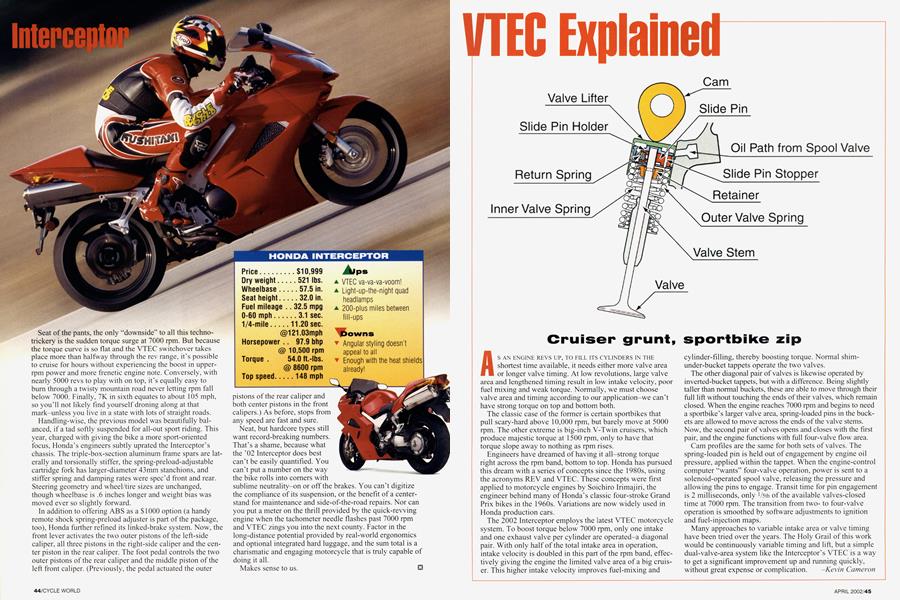

VTEC Explained

Cruiser grunt, sportbike zip

AS AN ENGINE REVS UP, TO FILL ITS CYLINDERS IN THE shortest time available, it needs either more valve area or longer valve timing. At low revolutions, large valve area and lengthened timing result in low intake velocity, poor fuel mixing and weak torque. Normally, we must choose valve area and timing according to our application-we can’t have strong torque on top and bottom both.

The classic case of the former is certain sportbikes that pull scary-hard above 10,000 rpm, but barely move at 5000 rpm. The other extreme is big-inch V-Twin cruisers, which produce majestic torque at 1500 rpm, only to have that torque slope away to nothing as rpm rises.

Engineers have dreamed of having it all-strong torque right across the rpm band, bottom to top. Honda has pursued this dream with a series of concepts since the 1980s, using the acronyms REV and VTEC. These concepts were first applied to motorcycle engines by Soichiro Irimajiri, the engineer behind many of Honda’s classic four-stroke Grand Prix bikes in the 1960s. Variations are now widely used in Honda production cars.

The 2002 Interceptor employs the latest VTEC motorcycle system. To boost torque below 7000 rpm, only one intake and one exhaust valve per cylinder are operated-a diagonal pair. With only half of the total intake area in operation, intake velocity is doubled in this part of the rpm band, effectively giving the engine the limited valve area of a big cruiser. This higher intake velocity improves fuel-mixing and

cylinder-filling, thereby boosting torque. Normal shimunder-bucket tappets operate the two valves.

The other diagonal pair of valves is likewise operated by inverted-bucket tappets, but with a difference. Being slightly taller than normal buckets, these are able to move through their full lift without touching the ends of their valves, which remain closed. When the engine reaches 7000 rpm and begins to need a sportbike’s larger valve area, spring-loaded pins in the buckets are allowed to move across the ends of the valve stems. Now, the second pair of valves opens and closes with the first pair, and the engine functions with full four-valve flow area.

Cam profiles are the same for both sets of valves. The spring-loaded pin is held out of engagement by engine oil pressure, applied within the tappet. When the engine-control computer “wants” four-valve operation, power is sent to a solenoid-operated spool valve, releasing the pressure and allowing the pins to engage. Transit time for pin engagement is 2 milliseconds, only 1/5th of the available valves-closed time at 7000 rpm. The transition from twoto four-valve operation is smoothed by software adjustments to ignition and fuel-injection maps.

Many approaches to variable intake area or valve timing have been tried over the years. The Holy Grail of this work would be continuously variable timing and lift, but a simple dual-valve-area system like the Interceptor’s VTEC is a way to get a significant improvement up and running quickly, without great expense or complication. -Kevin Cameron

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontLetter of the Month

April 2002 By David Edwards -

Leanings

LeaningsThe Mouse That Roared

April 2002 By Peter Egan -

TDC

TDCThe Rpm Chronicles

April 2002 By Kevin Cameron -

Departments

DepartmentsHotshots

April 2002 -

Roundup

RoundupNew Bmw Über-Tourer Twin

April 2002 By Matthew Miles -

Roundup

RoundupUltimate Towing Machine?

April 2002 By David Edwards