SERVICE

Paul Dean

A little slice of Pi

I am familiar with the equation used to calculate horsepower when the engine’s torque and rpm values are both known: HP = (torque x rpm) ÷ 5252. I do not know, however, where that 5252 constant came from. Can you explain?

Jeff McHugh Posted on www.cycleworld.com

An excellent question. I’ll try to answer it without getting too caught up in technobabble.

First, a brief terminology explanation. Torque is a measurement of force, but it does not necessarily produce any movement. When force causes movement, the result is called work. And the measurement of the amount of work performed over a given period of time is called power-not horsepower, but just plain “power.” Thus, the formula for calculating power is very simple: Force times Distance times Time.

Now, you’ve probably noticed that torque ratings never include an engine’s stroke dimensions. That’s because they don’t have to. Torque figures are always expressed in foot-pounds, which means they assume a lever distance (which is one-half of any crankshaft s stroke) of one foot, regardless of the engine s actual stroke.

To convert an engine’s torque output into power, we first have to determine how far that one-foot lever (the crankpin) travels during each engine revolution. The circumference of a circle is calculated by multiplying its diameter (the stroke) by Pi (3.14); so, for the purpose of calculating power, the distance traveled by the crankpin on each revolution of any engine always is 6.28 feet (3.14 x 2). An engineer, of course, would carry out Pi to at least 8 decimal places (3.14159265), but for this explanation, I’ve simply rounded it off to 3.14.

Now, let’s suppose we have an engine that makes 60 foot-pounds of torque at 11,000 rpm. If you multiply 60 (the torque) by 6.28 (the distance, in feet, the crankpin travels during each revolution) and then multiply by 11,000 (the number of revolutions in one minute), you get 4,144,800. In other words, the engine has a power rating of 4,144,800 foot-pounds of work per minute.

But that ’s just plain “power; ” what about horsepower? According to James Watt, who came up with that unit of measurement way back in the 18th century, one horsepower is 33,000 footpounds or work per minute. So, if you divide our hypothetical engine ’s power output (4,144,800) by one horsepower (33,000), you get 125.6, which is the amount of horsepower the engine makes at 11,000 rpm.

But there’s an easier way. With the method just described, you always have to multiply the rpm by 6.28 and divide the resultant power number by 33,000. Because that requisite never changes, you can use a mathematical shortcut-a constant-to calculate horsepower more quickly. That constant is 5252, which is 33,000 divided by 6.28 (actually, as explained earlier, the divisor is more like 6.2831853).

So, using this engine’s same torque output and rpm numbers, multiply 60 by 11,000 and divide by 5252. You get 125.6, which is the same horsepower figure obtained by the “long” method of calculation.

The sound and the fury

My question isn’t about motorcycle repair, it’s about motorcycle design: Why, on four-cylinder sportbikes, does the exhaust system end with just one muffler, yet two-cylinder sportbikes have two mufflers? K. Crosby

Posted on www.cycleworld.com

There are several reasons, some having to do with noise emissions, some with tuning. The two-cylinder sportbikes you are referring to are, I assume, V-Twins, which means they have uneven firing intervals. A 90-degree V-Twin, such as a Ducati or a Honda RC51, fires at 270450-degree intervals, while Aprilia ’s 60degree V-Twins fire at 300-420-degree intervals. Such uneven firing sequences complicate the task of allowing the engine to make optimum power at all reasonable rpm when just one muffler is employed. The exhaust waves from both cylinders interact inside that single muffler; and since the combustion events that create those waves are unevenly sequenced, the muffler’s tuning characteristics can be ideal over a wide rpm range for one cylinder but not quite so for the other. Instead, they usually end up being slightly compromised for both cylinders. Using two mufflers, one per cylinder, solves that problem and thus simplifies the pursuit of a wider powerband.

An inline-Four engine, on the other hand, which remains the most popular type of powerplant used in sportbikes, has even combustion intervals, with one cylinder firing every 180 degrees. A single muffler can, therefore, be tuned to deliver equal performance for all four cylinders.

Then there is the noise issue. Once again, I have to assume that you are talking mostly about large-displacement V-Twin sportbikes, the sizable exhaust pulses of which can be very difficult to quiet without seriously restricting performance. The key to this knotty problem is exhaust-system volume, which, obviously, is easier to achieve with two mufflers than with one. On four-cylinder engines, though, the exhaust pulses are much smaller and of higher frequency, and that makes them easier to quiet with just one muffer.

If you don’t have to meet restrictive noise regulations or deliver a broad powerband, however, all bets are off. As evidenced during this year’s AMA Superbike events, Nicky Hayden’s RC51 usually was the fastest machine on the track, despite using just one muffler, while the Ducatis of Chandler and Picotte still use two. Ditto in World Superbike, where Colin Edwards ’ one-muffler RC51 has been the only machine capable of consistently running with and even beating the twin-muffler Ducatis of Troy Bayliss and Neil Hodgdon.

Baffled and bewildered

I have made a few modifications to my 2001 Kawasaki ZX-6R, including installing a jet kit and opening up the baffles in the muffler. I recently had it dynotested at my local dealer, and the results show that there is a drop of 28 horsepower between 7700 and 9200 rpm, then an increase of 37 bhp from 9200 to 10,750, where it peaks and then drops 25 bhp before redlining at 14,500. The shop techs told me that the engine acts this way because it is running rich, which I believe, but I think it is doing so because the ramair intake doesn’t work when the bike is on a dyno. I would hate to install smaller main jets to achieve better numbers on the dyno, but have the engine run poorly on the street and strip. Right now, I don’t feel any of the dips and lags that the dyno indicates, particularly at the strip. Can you let me know what I should do?

James Ramsey Ordway, Colorado

You have a number of issues to deal with here, starting with your modification of the muffler. I don’t know how you “opened up the bajfles,’’ but I suspect it involved something along the lines of poking holes through them, or perhaps some other equally unscientific alteration. Just because the engine now makes more noise and has less exhaust backpressure doesn’t mean it runs better; based on your shop ’s dyno figures, it seems to run considerably worse, with giant holes in the powerband that weren’t there before. Our dyno test of the 2001 ZX-6R showed peak power arriving at 12,600 rpm, almost 2000 revs higher than on your bike, and nowhere in the rpm range was there anything close to a drop of 28 horsepower over a 1500-rpm spread. I wouldn’t expect your ZX-6R to make as much power as ours, since you and your shop are located at 4000 feet and we are at sea level, but the numbers shouldn’t fall as short

Recall Roster

NHTSA Recall No. 02V122 Victory V92C & V92TC, both Standard & Deluxe models Model year: 2000 Number of units involved: 1320 Dates of Manufacture: August ’01 to April ’02

Problem: The fuel-rail assembly for the fuel-injection system on these motorcycles contains a Schrader valve that may not be properly tightened, which could cause fuel leakage and a resultant fire. Remedies: Dealers will inspect the fuel rail and replace it if necessary. Owners who do not receive this free remedy within a reasonable time should contact Victory at 715/294-5331.

as you indicate.

Pardon my sarcasm, James, but if increasing an engine ’s performance were as simple as punching a few holes in the baffles, the bike manufacturers and the aftermarket exhaust companies would save billions each year in R&D costs. Just give Masanori or Giacomo or Billy Bob a hammer, a big punch and a pile of mufflers and let him have at it!

You are spot-on, however, when you surmise that a ram-air-inducted engine runs richer on a dyno than on the street. That’s a dilemma facing many people in the industry today, especially those who rely upon dynamometers as tuning and testing devices. Until someone develops a dyno with a fan system that can provide intake air speed that matches rear-wheel speed, dyno testing of ram-air bikes is going to be rather imprecise.

I have no way of knowing if your Kawasaki ’s jetting is too rich or too lean. But as a general guideline, I can tell you that the fuel-injection systems on the latest Suzuki GSX-Rs-which also have ram-air induction-are programmed to riehen the fuel mixture by about 5 percent when the engine is at full throttle and spinning above 8000 rpm in fifth and sixth gears. That information may not translate directly to a carbureted Kawasaki, but it might give you someplace to start.

Consequently, I can’t offer you much help with jetting your Kawasaki other than to suggest you do it the old-fashioned way: Run it wide-open in third or fourth gear for 8 to 10 seconds in a safe, secluded area, then simultaneously chop the throttle and switch off the engine. After you coast to a stop, read the sparkplugs and jet accordingly. I suspect that before it’s all over, though, you ’ll end up with an unmolested muffier-either stock or aftermarket-on your ZX-6R.

The wheels leak, too

I have a mint 1969 BSA 650cc Thunderbolt that I’ve owned since new. I recently bought two new Dunlop tubeless tires, a 100/90-19 Gold Seal II front and a 4.25-18 Gold Seal K127 rear.

I have been unable to find a correct pressure recommendation for these tires. The bike weighs 420 pounds and I weigh 170, and I always ride alone. Also, I’ve heard that tubeless tires should only be put on mag wheels and that tubes should be used with spoked wheels such as on my BSA. I no longer go on high-speed long runs but do ride on the local charity/poker runs. Should I use tubes with these tires?

Ted Galus Bayville, New Jersey

Not only should you use tubes in your BSA ’s tires, you have no real alternative. The spoked wheels on that bike were designed long before motorcycles began using tubeless tires; so, even if you did attempt to mount your new Dunlops without tubes, most of the air would likely leak out past the spoke nipples before you could get the wheels back on the bike. With only a few specially designed exceptions, even modern wire-spoke wheels require tubes in their tires.

As far as tire pressures are concerned, BSA only recommended 18 psi in the front and 20 in the rear back in 1969. But riding conditions and tire technology were different then than now; as a result, I suggest you use about 24-26 psi in the front tire and 26-28 in the rear. If you do go on any higher-speed runs, especially if you ride two-up, bump those pressures up to 26-28 in front and 28-30 in the rear.

Valves on the loose

My 2000 Yamaha R1 has a ticking sound that’s coming from the top half of the engine, and I’m sure it’s being caused by excessive clearance on one of the valves.

I was planning to check the clearances this coming winter, but I want to ride another 2000 miles before then. Should I wait until winter to have the valves checked or do it now? If any damage were to occur between now and then, would it be with the cam lobe or the shim bucket? I would guess that both the cam and the bucket are ultra-hard and can stand up to the light impact that’s causing the sound I’m now hearing. I don’t race the bike, and I hardly 1 ever shift above 8000 rpm. I really don’t have the money to have a shop fix it now, and I don’t want to park the bike during the good riding season.

Justin Yost Northampton, Pennsylvania

Here ’s the harsh reality of the matter: Your Rl’s loose valve doesn’t care whether or not you have the money for a clearance adjustment or if you miss part of the riding season out there in Pennsyltucky. If the valve has enough clearance to beat some part of the valvetrain into submission over the next couple of thousand miles, that’s what ’s going to happen. And since I am about 2700 miles distant from the bike and can’t hear the ticking for myself, I am unable to tell you whether or not it is a potentially damaging noise.

But I can tell you that the most likely victim of prolonged running with excessive valve clearance is not the cam lobe or the bucket; it is the valve itself and its mating valve seat. Most street-oriented cam lobes are ground with “quieting” ramps that allow the lobes to start the opening and end the closing of the valves comparatively gently. This not only helps the engine run quietly enough to pass federal noise standards, it also extends valve life by cushioning the impact of valve closure. But when the clearance becomes excessive, the quieting ramps can’t do their job, so the lobes effectively “bang ” the valves open and let them “slam ” shut. Over time, the abrupt closing tends to hammer the heads of the affected valves and their seats, often enough that those components need to be reground or replaced. That requires removal, disassembly, repair, reassembly and reinstallation of the cylinder head, which is a far more expensive procedure than simply having the valves adjusted.

So, since you intend to have a valve adjustment done this winter anyway, the question you need to ask yourself is similar to the one posed in those oil-filter commercials: Do you pay a little now or face the possibility of paying a lot later?

Wake up, little Suzi

I just bought my girlfriend a used 2000 Suzuki GS500 that only has 1100 miles on it. I got it dirt-cheap, even though it’s in like-new condition. It’s a perfect bike for her size and ability, except for one thing: It runs like crap. It starts right up, but then it sputters and hesitates and wants to stall. It runs pretty well once it warms up, but that sometimes takes a ridiculously long time, like maybe 10 or 15 miles of steady running. Do you have any idea what might be wrong? Davey Sanchez

Bryan, Texas

Relief is just a jet kit away. The GS500 is a terrific little bike, but its two-valve-percylinder engine is late-1980’s technology, particularly in its combustion-chamber design. Consequently, getting the engine to meet contemporary EPA emissions standards required Suzuki to jet the GSs carbs somewhere on the fuel-starvation side of lean. That s why the engine balks and stutters until it reaches full operating temperature, and even then, it still could use more combustibles in the fuel mixture.

Recall Roster

NHTSA Recalls No. 02V124 & 02V144 Indian Chief

Model years: 1999-2000 Number of units involved: 4590 Dates of Manufacture: June ’99 to October ’00

Problem 1: On certain models equipped with rear shocks made by Sway-A-Way, the bolts that attach the shocks to the swingarm could break, potentially resulting in the collapse of the rear suspension. Problem 2: On certain models, the top clamp on the handlebar riser could allow excessive movement of the handlebars, possibly causing the rider to lose control of the motorcycle.

Remedies: Dealers will inspect the rear shocks and replace them if necessary, and fit a new handlebar-riser top clamp. Owners who do not receive these free remedies within a reasonable time should contact Indian at 408/846-7228.

Fortunately, Dynojet (800/992-4993; www.dvnoiet.com) sells a jet kit that greatly improves the little GS s driveability. The kit (part #3128 for the Stage 1 level, which is all that an otherwise stock GS500 needs) lists for about $83 and contains new main jets, jet needles and a few other bits and pieces necessary for the modification. If you’ve ever taken apart and successfully reassembled a motorcycle carb, you ’ll find the kit relatively easy to install; if not, you probably ought to let a capable mechanic tackle the job.

Got a mechanical or technical problem with your beloved ride? Can’t seem to find reasonable solutions in your area? Maybe we can help. If you think we can, either: 1) Mail your inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; 3) e-mail it to CW1Dean@aol.com, or 4) log onto www.cycleworld.com and click on the Feedback button. Please, always include your name, city and state of residence. Don’t write a 10page essay, but do include enough information about the problem to permit a rational diagnosis. And please understand that due to the enormous volume of inquiries we receive, we can’t guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

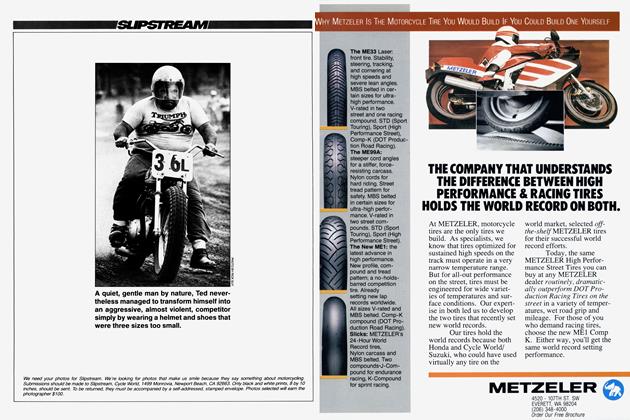

Up FrontThe Other Side of Speed

November 2002 By David Edwards -

Leanings

LeaningsA Morning In Italy

November 2002 By Peter Egan -

TDC

TDCLiving In Harmony

November 2002 By Kevin Cameron -

Departments

DepartmentsHotshots

November 2002 -

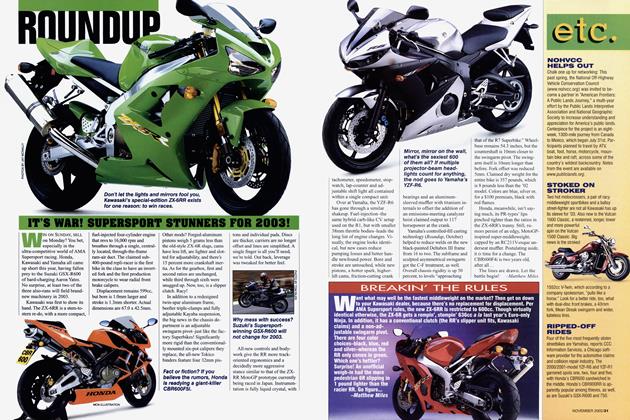

Roundup

RoundupIt's War! Supersport Stunners For 2003!

November 2002 By Matthew Miles -

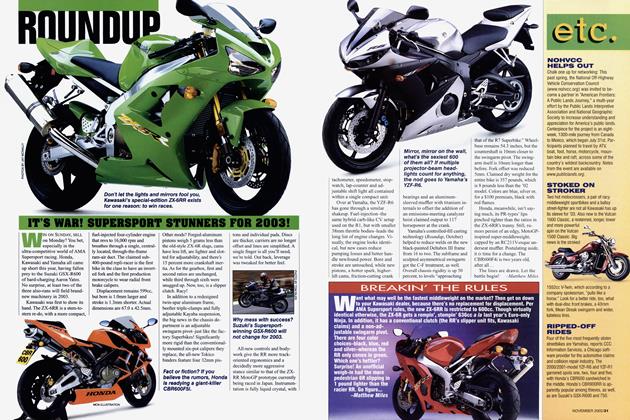

Roundup

RoundupBreakin' the Rules

November 2002 By Matthew Miles