Featherweights

SPECIAL SECTION

Shaving pounds-and seconds-with a quartet of pared-down Ducks

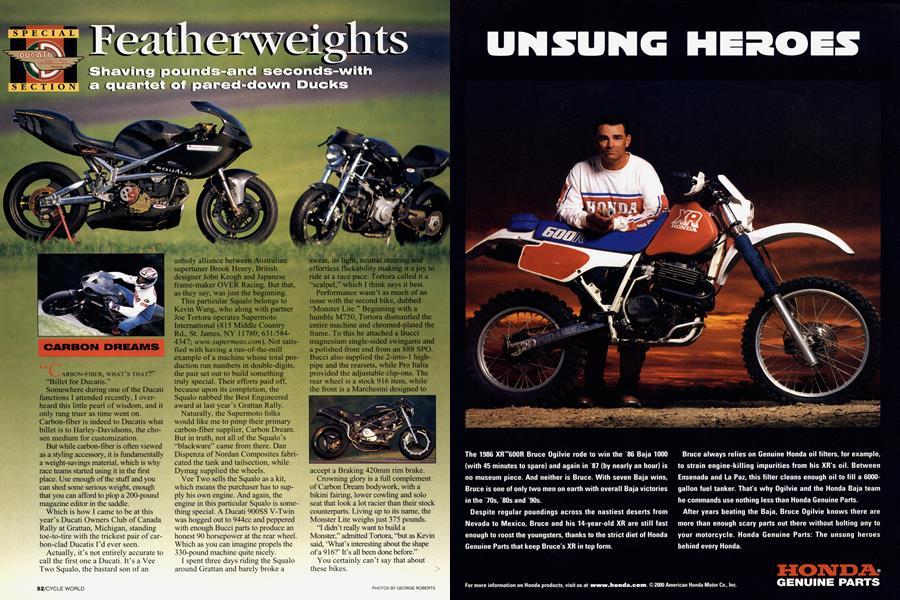

CARBON DREAMS

"CARBON-FIBER, WHAT'S THAT?" "Billet for Ducatis."

Somewhere during one of the Ducati functions I attended recently, I overheard this little pearl of wisdom, and it only rang truer as time went on. Carbon-fiber is indeed to Ducatis what billet is to Harley-Davidsons, the chosen medium for customization.

But while carbon-fiber is often viewed as a styling accessory, it is fundamentally a weight-savings material, which is why race teams started using it in the first place. Use enough of the stuff and you can shed some serious weight, enough that you can afford to plop a 200-pound magazine editor in the saddle.

Which is how I came to be at this year’s Ducati Owners Club of Canada Rally at Grattan, Michigan, standing toe-to-tire with the trickest pair of carbon-clad Ducatis I’d ever seen.

Actually, it’s not entirely accurate to call the first one a Ducati. It’s a Vee Two Squalo, the bastard son of an unholy alliance between Australian supertuner Brook Henry, British designer John Keogh and Japanese frame-maker OVER Racing. But that, as they say, was just the beginning.

This particular Squalo belongs to Kevin Wang, who along with partner Joe Tortora operates Supermoto International (815 Middle Country Rd., St. James, NY 11780; 631/5844347; www.supennoto.com). Not satisfied with having a run-of-the-mill example of a machine whose total production run numbers in double-digits, the pair set out to build something truly special. Their efforts paid off, because upon its completion, the Squalo nabbed the Best Engineered award at last year’s Grattan Rally.

Naturally, the Supermoto folks would like me to pimp their primary carbon-fiber supplier, Carbon Dream. But in truth, not all of the Squalo’s “blackware” came from there. Dan Dispenza of Nordan Composites fabricated the tank and tailsection, while Dymag supplied the wheels.

Vee Two sells the Squalo as a kit, which means the purchaser has to supply his own engine. And again, the engine in this particular Squalo is something special. A Ducati 900SS V-Twin was hogged out to 944cc and peppered with enough Bucci parts to produce an honest 90 horsepower at the rear wheel. Which as you can imagine propels the 330-pound machine quite nicely.

I spent three days riding the Squalo around Grattan and barely broke a sweat, its light, neutral st effortless flickability making it a joy to ride at a race pace. Tortora called it a “scalpel,” which I think says it best.

Performance wasn’t as much of an issue with the second bike, dubbed “Monster Lite.” Beginning with a humble M750, Tortora dismantled the entire machine and chromed-plated the frame. To this he attached a Bucci magnesium single-sided swingarm and a polished front end from an 888 SPO. Bucci also supplied the 2-into-l highpipe and the rearsets, while Pro Italia provided the adjustable clip-ons. The rear wheel is a stock 916 item, while the front is a Marchesini designed to accept a Braking 420mm rim brake.

Crowning glory is a full complement of Carbon Dream bodywork, with a bikini fairing, lower cowling and solo seat that look a lot racier than their stock counterparts. Living up to its name, the Monster Lite weighs just 375 pounds.

“I didn’t really want to build a Monster,” admitted Tortora, “but as Kevin said, ‘What’s interesting about the shape of a 916?’ It’s all been done before.”

You certainly can’t say that about these bikes.

DESMO COCKTAIL

w HAT DO YOU DO WHEN YOU CAN’T decide between a 916 and a 900SS? Build a bike that’s a little bit of both.

Alex Ortner calls his one-of-a-kind Ducati hybrid the 908 SSP, because it’s halfway between a 900 and a 916 (the “P” stands for prototype). More accurately, it’s a 916 in front and back, and a 900SS in the middle. Or as Ortner himself put it, “What I think Ducati should have built, and might have if Tamburini had stayed with Ducati instead of going with Cagiva.”

The project began in July, 1998, when the Michigan machinist acquired a 1996 900SS-SP from a Cincinnati Bengal whose football contract forbade motorcycling. Ortner clenched his teeth and hacksawed the frame just north of the swingarm pivot, welded on a couple of inches from a 916, and then bolted on a 916 subframe. He modified a single-sided 916 swingarm to pivot in the 900’s engine cases, fabricated a new steering stem to accommodate a 916 front end, and mounted up 916 wheels, fenders, tailsection and upper fairing. The 5-gallon fiberglass fuel tank came from Action Sport Cycles, while the carbon lower cowling was hand-laid using a Bimota DB4 mold acquired from Supermoto International.

While the project obviously wasn’t cheap, Ortner economized by purchasing the 916 parts from wrecks and selling the disused SP parts to CR owners looking to upgrade.

Two years and 5000 miles later, he’s still enjoying his 360-pound creation. As did I when I took it for a spin at Grattan-right up to the point that the adjustable clip-ons bent down, the twistgrip stuck on the bar end and I nearly crashed entering the fastest corner on the racetrack! Tighten those two bolts, and the 908 SSP would work as good as it looks.

DUCK A L'ORANGE

TMPROVING THE HANDLING OF A Ducati Superbike is a daunting proposition just ask the factory race team. But for a couple of dedicated enthusiasts from New Hampshire, it was a simple matter of starting from scratch

Welder extraordinaire Doug Cook runs BCD Fabrication (603/528-1160; wuw.bed)abrication.com) and has been fabricating frames for air-cooled Ducatis since 1992. Besides reducing weight, Cook’s 11 4-inch thin-wall chromoly structures optimize weight distribution by rotating the engine 10 degrees downward and moving it so far forward that the horizontal cylinder head nearly rubs on the front tire. The design also offers greater adjustability than stock, with variable rake, trail. wheelbase, ride height and shock leverage ratio.

When Cook and partner-in-crime Leslie Grossman set out to build a raeebike for the AMA Pro Thunder Series, however, they determined that a liquid-cooled 748 would be the way to go. But the duo didn’t want to just hang the radiator in front of the engine, where it would hinder aerodynamics and weight bias. So, taking a cue from the late John Britten, they put it under the seat.

Unfortunately, they hadn’t quite worked out the airflow by the Grattan Rally, which meant the bike was plagued by overheating. I was offered a ride on the 320-pound machine, but after 1 saw racer Eric Gulbranson nearly high-side it when coolant got on the rear tire, I took a rain check.

The event wasn't a complete wash, however, because the DOCC judges presented Cook and Grossman with this year’s Best Engineered award, upsetting a certain carbon-liber Monster. But as the gracious loser put it, “1 totally respect the judges' decision. Alter all, we built our bike using bolt-on parts, whereas these guys made the frame and everything. You’ve got to appreciate their effort."

You certainly do.

Brian Catterson

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontShameless Plugs

November 2000 By David Edwards -

Leanings

LeaningsThe Convertible

November 2000 By Peter Egan -

TDC

TDCGp Four-Strokes

November 2000 By Kevin Cameron -

Departments

DepartmentsHotshots

November 2000 -

Roundup

RoundupDan Gurney's Alligator: Alternative Corner Carver

November 2000 By Kevin Cameron -

Roundup

RoundupHart Attack

November 2000 By Eric Johnson