The OW Papers

Works Weapon

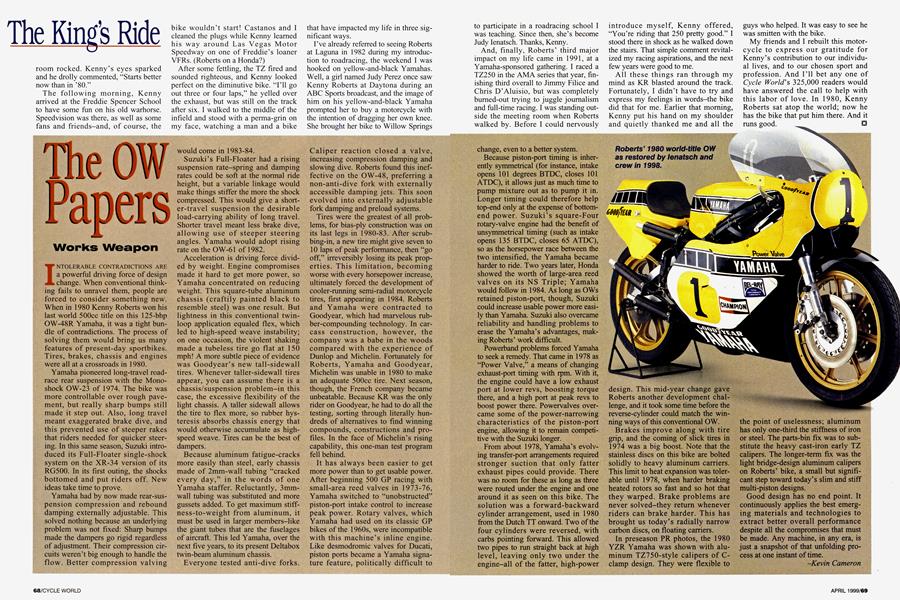

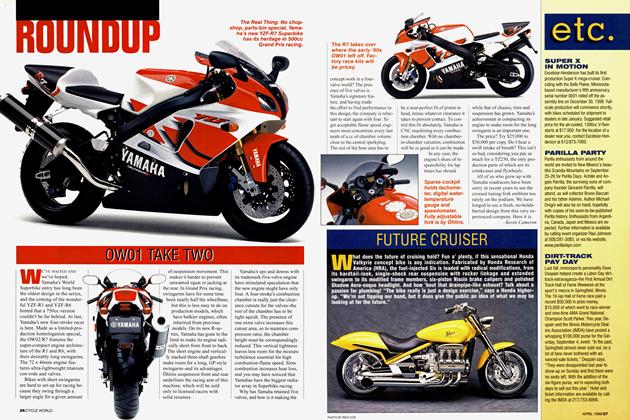

INTOLERABLE CONTRADICTIONS ARE a powerful driving force of design change. When conventional thinking fails to unravel them, people are forced to consider something new. When in 1980 Kenny Roberts won his last world 500cc title on this 125-bhp OW-48R Yamaha, it was a tight bundle of contradictions. The process of solving them would bring us many features of present-day sportbikes. Tires, brakes, chassis and engines were all at a crossroads in 1980.

Yamaha pioneered long-travel roadrace rear suspension with the Monoshock OW-23 of 1974. The bike was more controllable over rough pavement, but really sharp bumps still made it step out. Also, long travel meant exaggerated brake dive, and this prevented use of steeper rakes that riders needed for quicker steering. In this same season, Suzuki introduced its Full-Floater single-shock system on the XR-34 version of its RG500. In its first outing, the shocks bottomed and put riders off. New ideas take time to prove.

Yamaha had by now made rear-suspension compression and rebound damping externally adjustable. This solved nothing because an underlying problem was not fixed: Sharp bumps made the dampers go rigid regardless of adjustment. Their compression circuits weren’t big enough to handle the flow. Better compression valving

would come in 1983-84.

Suzuki’s Full-Floater had a rising suspension rate-spring and damping rates could be soft at the normal ride height, but a variable linkage would make things stiffer the more the shock compressed. This would give a shorter-travel suspension the desirable load-carrying ability of long travel. Shorter travel meant less brake dive, allowing use of steeper steering angles. Yamaha would adopt rising rate on the OW-61 of 1982.

Acceleration is driving force divided by weight. Engine compromises made it hard to get more power, so Yamaha concentrated on reducing weight. This square-tube aluminum chassis (craftily painted black to resemble steel) was one result. But lightness in this conventional twinloop application equaled flex, which led to high-speed weave instability; on one occasion, the violent shaking made a tubeless tire go flat at 150 mph! A more subtle piece of evidence was Goodyear’s new tall-sidewall tires. Whenever taller-sidewall tires appear, you can assume there is a chassis/suspension problem-in this case, the excessive flexibility of the light chassis. A taller sidewall allows the tire to flex more, so rubber hysteresis absorbs chassis energy that would otherwise accumulate as highspeed weave. Tires can be the best of dampers.

Because aluminum fatigue-cracks more easily than steel, early chassis made of 2mm-wall tubing “cracked every day,” in the words of one Yamaha staffer. Reluctantly, 3mmwall tubing was substituted and more gussets added. To get maximum stiffness-to-weight from aluminum, it must be used in larger members-like the giant tubes that are the fuselages of aircraft. This led Yamaha, over the next five years, to its present Deltabox twin-beam aluminum chassis.

Everyone tested anti-dive forks.

Caliper reaction closed a valve, increasing compression damping and slowing dive. Roberts found this ineffective on the OW-48, preferring a non-anti-dive fork with externally accessible damping jets. This soon evolved into externally adjustable fork damping and preload systems.

Tires were the greatest of all problems, for bias-ply construction was on its last legs in 1980-83. After scrubbing-in, a new tire might give seven to 10 laps of peak performance, then “go off,” irreversibly losing its peak properties. This limitation, becoming worse with every horsepower increase, ultimately forced the development of cooler-running semi-radial motorcycle tires, first appearing in 1984. Roberts and Yamaha were contracted to Goodyear, which had marvelous rubber-compounding technology. In carcass construction, however, the company was a babe in the woods compared with the experience of Dunlop and Michelin. Fortunately for Roberts, Yamaha and Goodyear, Michelin was unable in 1980 to make an adequate 500cc tire. Next season, though, the French company became unbeatable. Because KR was the only rider on Goodyear, he had to do all the testing, sorting through literally hundreds of alternatives to find winning compounds, constructions and profiles. In the face of Michelin’s rising capability, this one-man test program fell behind.

It has always been easier to get more power than to get usable power. After beginning 500 GP racing with small-area reed valves in 1973-76, Yamaha switched to “unobstructed” piston-port intake control to increase peak power. Rotary valves, which Yamaha had used on its classic GP bikes of the 1960s, were incompatible with this machine’s inline engine. Like desmodromic valves for Ducati, piston ports became a Yamaha signature feature, politically difficult to change, even to a better system.

Because piston-port timing is inherently symmetrical (for instance, intake opens 101 degrees BTDC, closes 101 ATDC), it allows just as much time to pump mixture out as to pump it in. Longer timing could therefore help top-end only at the expense of bottomend power. Suzuki’s square-Four rotary-valve engine had the benefit of unsymmetrical timing (such as intake opens 135 BTDC, closes 65 ATDC), so as the horsepower race between the two intensified, the Yamaha became harder to ride. Two years later, Honda showed the worth of large-area reed valves on its NS Triple; Yamaha would follow in 1984. As long as OWs retained piston-port, though, Suzuki could increase usable power more easily than Yamaha. Suzuki also overcame reliability and handling problems to erase the Yamaha’s advantages, making Roberts’ work difficult.

Powerband problems forced Yamaha to seek a remedy. That came in 1978 as “Power Valve,” a means of changing exhaust-port timing with rpm. With it, the engine could have a low exhaust port at lower revs, boosting torque there, and a high port at peak revs to boost power there. Powervalves overcame some of the power-narrowing characteristics of the piston-port engine, allowing it to remain competitive with the Suzuki longer.

From about 1978, Yamaha’s evolving transfer-port arrangements required stronger suction that only fatter exhaust pipes could provide. There was no room for these as long as three were routed under the engine and one around it as seen on this bike. The solution was a forward-backward cylinder arrangement, used in 1980 from the Dutch TT onward. Two of the four cylinders were reversed, with carbs pointing forward. This allowed two pipes to run straight back at high level, leaving only two under the engine-all of the fatter, high-power

design. This mid-year change gave Roberts another development challenge, and it took some time before the reverse-cylinder could match the winning ways of this conventional OW.

Brakes improve along with tire grip, and the coming of slick tires in 1974 was a big boost. Note that the stainless discs on this bike are bolted solidly to heavy aluminum carriers. This limit to heat expansion was tolerable until 1978, when harder braking heated rotors so fast and so hot that they warped. Brake problems are never solved-they return whenever riders can brake harder. This has brought us today’s radially narrow carbon discs, on floating carriers.

In preseason PR photos, the 1980 YZR Yamaha was shown with aluminum TZ750-style calipers of Cclamp design. They were flexible to

the point of uselessness; aluminum has only one-third the stiffness of iron or steel. The parts-bin fix was to substitute the heavy cast-iron early TZ calipers. The longer-term fix was the light bridge-design aluminum calipers on Roberts’ bike, a small but significant step toward today’s slim and stiff multi-piston designs.

Good design has no end point. It continuously applies the best emerging materials and technologies to extract better overall performance despite all the compromises that must be made. Any machine, in any era, is just a snapshot of that unfolding process at one instant of time.

Kevin Cameron