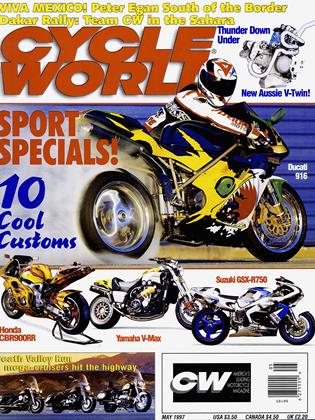

THUNDER DOWN UNDER!

ROUNDUP

PEOPLE ARE ALWAYS TALKing about the Australian "rider factory," that hidden crucible of Down Under riding talent that has produced such world-class roadracers as Wayne Gardner, Mick Doohan, Troy Corser and Anthony Gobert. Well, now comes the Australian motorcycle factory.

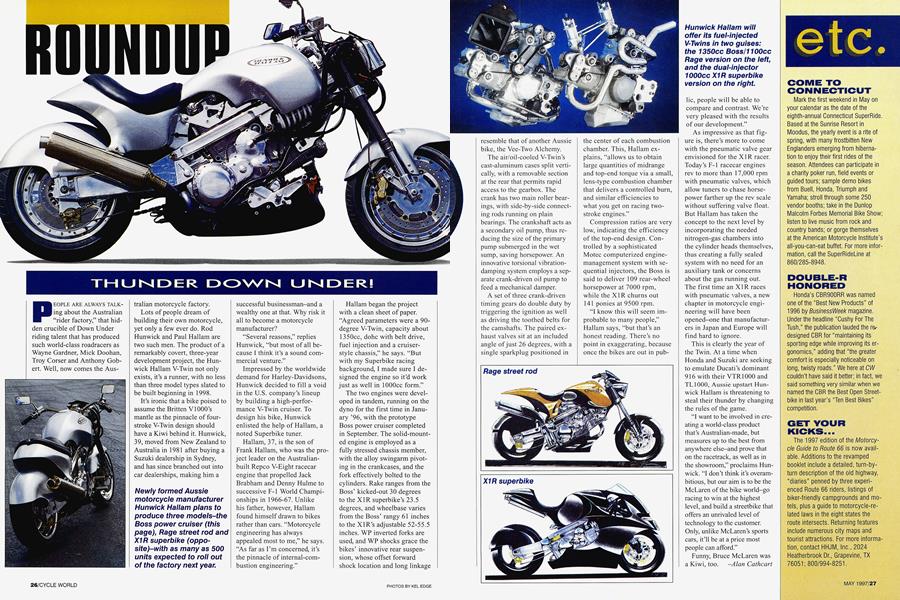

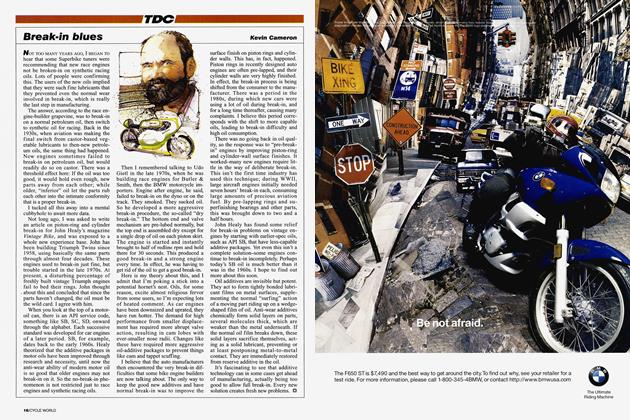

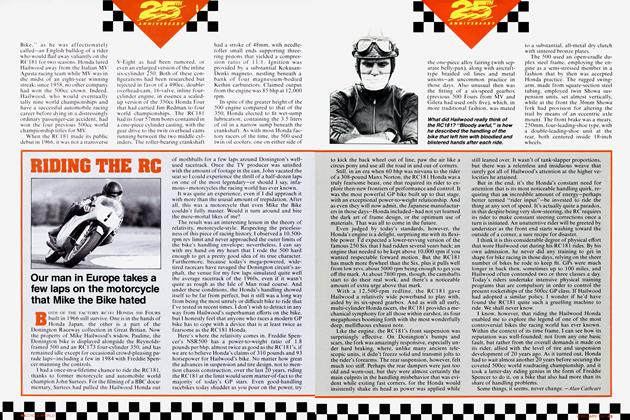

Lots of people dream of building their own motorcycle, yet only a few ever do. Rod Hunwick and Paul Hallam are two such men. The product of a remarkably covert, three-year development project, the Hunwick Hallam V-Twin not only exists, it’s a runner, with no less than three model types slated to be built beginning in 1998.

It’s ironic that a bike poised to assume the Britten VI000’s mantle as the pinnacle of fourstroke V-Twin design should have a Kiwi behind it. Hunwick, 39, moved from New Zealand to Australia in 1981 after buying a Suzuki dealership in Sydney, and has since branched out into car dealerships, making him a successful businessman-and a wealthy one at that. Why risk it all to become a motorcycle manufacturer?

“Several reasons,” replies Hunwick, “but most of all because I think it’s a sound commercial venture.”

Impressed by the worldwide demand for Harley-Davidsons, Hunwick decided to fill a void in the U.S. company’s lineup by building a high-performance V-Twin cruiser. To design his bike, Hunwick enlisted the help of Hallam, a noted Superbike tuner.

Hallam, 37, is the son of Frank Hallam, who was the project leader on the Australianbuilt Repco V-Eight racecar engine that propelled Jack Brabham and Denny Hulme to successive F-l World Championships in 1966-67. Unlike his father, however, Hallam found himself drawn to bikes rather than cars. “Motorcycle engineering has always appealed most to me,” he says. “As far as I’m concerned, it’s the pinnacle of internal-combustion engineering.”

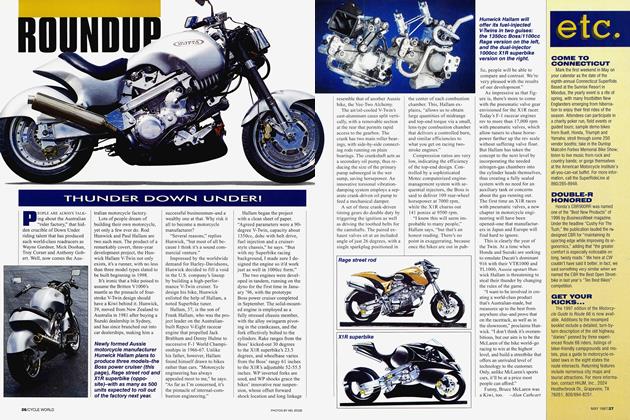

Hallam began the project with a clean sheet of paper. “Agreed parameters were a 90degree V-Twin, capacity about 1350cc, dohc with belt drive, fuel injection and a cruiserstyle chassis,” he says. “But with my Superbike racing background, I made sure I designed the engine so it’d work just as well in lOOOcc form.” The two engines were developed in tandem, running on the dyno for the first time in January ’96, with the prototype Boss power cruiser completed in September. The solid-mounted engine is employed as a fully stressed chassis member, with the alloy swingarm pivoting in the crankcases, and the fork effectively bolted to the cylinders. Rake ranges from the Boss’ kicked-out 30 degrees to the XIR superbike’s 23.5 degrees, and wheelbase varies from the Boss’ rangy 61 inches to the XIR’s adjustable 52-55.5 inches. WP inverted forks are used, and WP shocks grace the bikes’ innovative rear suspension, whose offset forward shock location and long linkage resemble that of another Aussie bike, the Vee-Two Alchemy.

The air/oil-cooled V-Twin’s cast-aluminum cases split vertically, with a removable section at the rear that permits rapid access to the gearbox. The crank has two main roller bearings, with side-by-side connecting rods running on plain bearings. The crankshaft acts as a secondary oil pump, thus reducing the size of the primary pump submerged in the wet sump, saving horsepower. An innovative torsional vibrationdamping system employs a separate crank-driven oil pump to feed a mechanical damper.

A set of three crank-driven timing gears do double duty by triggering the ignition as well as driving the toothed belts for the camshafts. The paired exhaust valves sit at an included angle of just 26 degrees, with a single sparkplug positioned in the center of each combustion chamber. This, Hallam explains, “allows us to obtain large quantities of midrange and top-end torque via a small, lens-type combustion chamber that delivers a controlled burn, and similar efficiencies to what you get on racing twostroke engines.”

Compression ratios are very low, indicating the efficiency of the top-end design. Controlled by a sophisticated Motee computerized enginemanagement system with sequential injectors, the Boss is said to deliver 109 rear-wheel horsepower at 7000 rpm, while the XIR churns out 141 ponies at 9500 rpm.

“I know this will seem improbable to many people,” Hallam says, “but that’s an honest reading. There’s no point in exaggerating, because once the bikes are out in publie, people will be able to compare and contrast. We’re very pleased with the results of our development.”

As impressive as that figure is, there’s more to come with the pneumatic valve gear envisioned for the XIR racer. Today’s F-l racecar engines rev to more than 17,000 rpm with pneumatic valves, which allow tuners to chase horsepower farther up the rev scale without suffering valve float. But Hallam has taken the concept to the next level by incorporating the needed nitrogen-gas chambers into the cylinder heads themselves, thus creating a fully sealed system with no need for an auxiliary tank or concerns about the gas running out.

The first time an XIR races with pneumatic valves, a new chapter in motorcycle engineering will have been opened-one that manufacturers in Japan and Europe will find hard to ignore.

This is clearly the year of the Twin. At a time when Honda and Suzuki are seeking to emulate Ducati’s dominant 916 with their VTR1000 and TL1000, Aussie upstart Hunwick Hallam is threatening to steal their thunder by changing the rules of the game.

“I want to be involved in creating a world-class product that’s Australian-made, but measures up to the best from anywhere else-and prove that on the racetrack, as well as in the showroom,” proclaims Hunwick. “I don’t think it’s overambitious, but our aim is to be the McLaren of the bike world-go racing to win at the highest level, and build a streetbike that offers an unrivaled level of technology to the customer. Only, unlike McLaren’s sports cars, it’ll be at a price most people can afford.”

Funny, Bruce McLaren was a Kiwi, too. Alan Cathcart