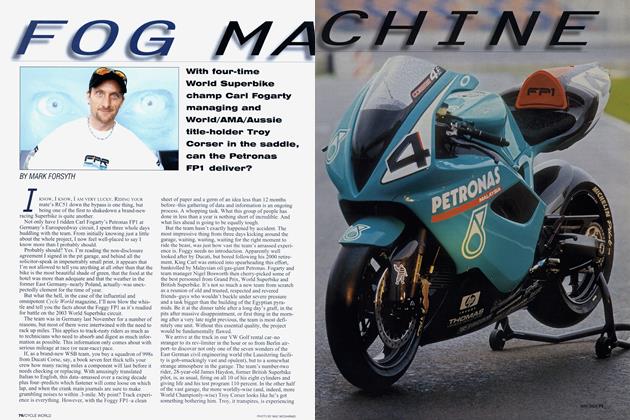

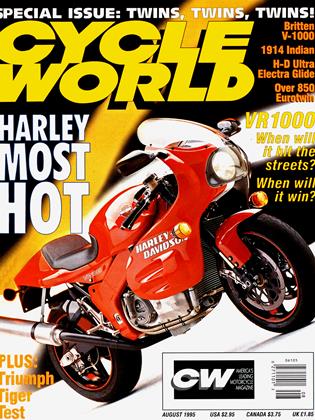

TOUR OF BRITTEN

INSIDE THE V-1000

BY NOW, WE'VE ALL SEEN THE RESULTS OF JOHN Britten's labor, a stunningly beautiful, stunningly fast motorcycle.

It began as it should, with the engine, which was designed with strength in mind. It has to be.

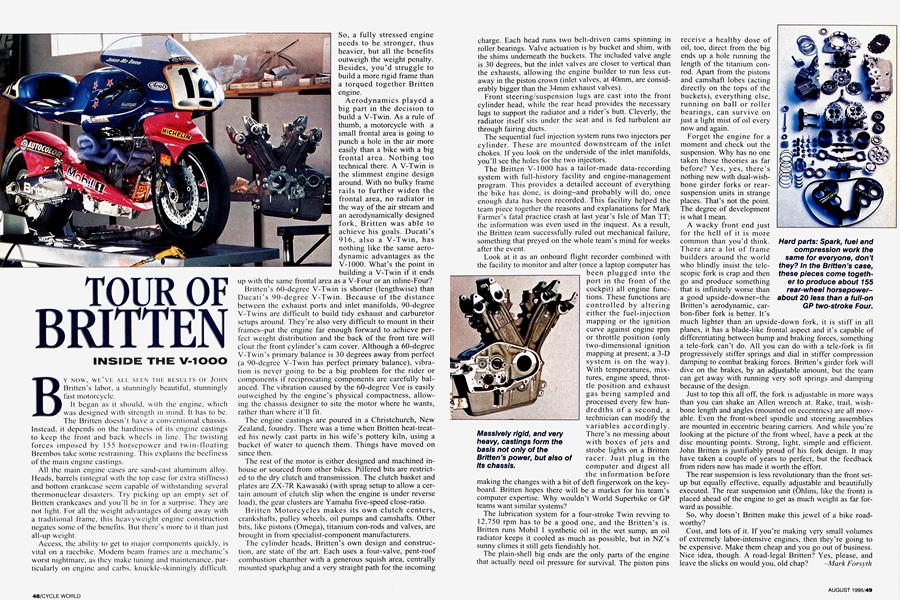

The Britten doesn’t have a conventional chassis. Instead, it depends on the hardiness of its engine castings to keep the front and back wheels in line. The twisting forces imposed by 155 horsepower and twin-floating Brembos take some restraining. This explains the beefiness of the main engine castings.

All the main engine cases are sand-cast aluminum alloy. Heads, barrels (integral with the top case for extra stiffness) and bottom crankcase seem capable of withstanding several thermonuclear disasters. Try picking up an empty set of Britten crankcases and you'll be in for a surprise. They are not light. For all the weight advantages of doing away with a traditional frame, this heavyweight engine construction negates some of the benefits. But there’s more to it than just all-up weight.

Access, the ability to get to major components quickly, is vital on a racebike. Modern beam frames are a mechanic’s worst nightmare, as they make tuning and maintenance, particularly on engine and carbs, knuckle-skinningly difficult. So, a fully stressed engine needs to be stronger, thus heavier, but all the benefits outweigh the weight penalty. Besides, you’d struggle to build a more rigid frame than a torqued together Britten engine.

Aerodynamics played a big part in the decision to build a V-Twin. As a rule of thumb, a motorcycle with a small frontal area is going to punch a hole in the air more easily than a bike with a big frontal area. Nothing too technical there. A V-Twin is the slimmest engine design around. With no bulky frame rails to further widen the frontal area, no radiator in the way of the air stream and an aerodynamically designed fork, Britten was able to achieve his goals. Ducati’s 916, also a V-Twin, has nothing like the same aerodynamic advantages as the V-1000. What’s the point in building a V-Twin if it ends

up with the same frontal area as a V-Four or an inline-Four?

Britten’s 60-degree V-Twin is shorter (lengthwise) than Ducati’s 90-degree V-Twin. Because of the distance between the exhaust ports and inlet manifolds, 90-degree V-Twins are difficult to build tidy exhaust and carburetor setups around. They’re also very difficult to mount in their frames-put the engine far enough forward to achieve perfect weight distribution and the back of the front tire will clout the front cylinder’s cam cover. Although a 60-degree V-Twin’s primary balance is 30 degrees away from perfect (a 90-degree V-Twin has perfect primary balance), vibration is never going to be a big problem for the rider or components if reciprocating components are carefully balanced. The vibration caused by the 60-degree Vee is easily outweighed by the engine’s physical compactness, allowing the chassis designer to site the motor where he wants, rather than where it’ll fit.

The engine castings are poured in a Christchurch, New Zealand, foundry. There was a time when Britten heat-treated his newly cast parts in his wife’s pottery kiln, using a bucket of water to quench them. Things have moved on since then.

The rest of the motor is either designed and machined inhouse or sourced from other bikes. Pilfered bits are restricted to the dry clutch and transmission. The clutch basket and plates are ZX-7R Kawasaki (with sprag setup to allow a certain amount of clutch slip when the engine is under reverse load), the gear clusters are Yamaha five-speed close-ratio.

Britten Motorcycles makes its own clutch centers, crankshafts, pulley wheels, oil pumps and camshafts. Other bits, like pistons (Omega), titanium con-rods and valves, are brought in from specialist-component manufacturers.

The cylinder heads, Britten’s own design and construction, are state of the art. Each uses a four-valve, pent-roof combustion chamber with a generous squish area, centrally mounted sparkplug and a very straight path for the incoming charge. Each head runs two belt-driven cams spinning in roller bearings. Valve actuation is by bucket and shim, with the shims underneath the buckets. The included valve angle is 30 degrees, but the inlet valves are closer to vertical than the exhausts, allowing the engine builder to run less cutaway in the piston crown (inlet valves, at 40mm, are considerably bigger than the 34mm exhaust valves).

Front steering/suspension lugs are cast into the front cylinder head, while the rear head provides the necessary lugs to support the radiator and a rider’s butt. Cleverly, the radiator itself sits under the seat and is fed turbulent air through fairing ducts.

The sequential fuel injection system runs two injectors per cylinder. These are mounted downstream of the inlet chokes. If you look on the underside of the inlet manifolds, you’ll see the holes for the two injectors.

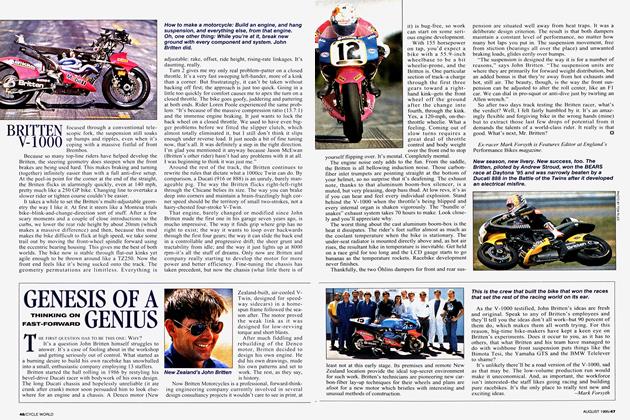

The Britten V-1000 has a tailor-made data-recording system with full-history facility and engine-management program. This provides a detailed account of everything the bike has done, is doing-and probably will do, once enough data has been recorded. This facility helped the team piece together the reasons and explanations for Mark Farmer’s fatal practice crash at last year’s Isle of Man TT; the information was even used in the inquest. As a result, the Britten team successfully ruled out mechanical failure, something that preyed on the whole team’s mind for weeks after the event.

Look at it as an onboard flight recorder combined with the facility to monitor and alter (once a laptop computer has

been plugged into the port in the front of the cockpit) all engine functions. These functions are controlled by altering either the fuel-injection mapping or the ignition curve against engine rpm or throttle position (only two-dimensional ignition mapping at present; a 3-D system is on the way). With temperatures, mixtures, engine speed, throttle position and exhaust gas being sampled and processed every few hundredths of a second, a technician can modify the variables accordingly. There’s no messing about with boxes of jets and strobe lights on a Britten racer. Just plug in the computer and digest all the information before

making the changes with a bit of deft fingerwork on the keyboard. Britten hopes there will be a market for his team’s computer expertise. Why wouldn’t World Superbike or GP teams want similar systems?

The lubrication system for a four-stroke Twin revving to 12,750 rpm has to be a good one, and the Britten’s is.

Britten runs Mobil 1 synthetic oil in the wet sump, an oil

radiator keeps it cooled as much as possible, but in NZ’s sunny climes it still gets fiendishly hot.

The plain-shell big ends are the only parts of the engine that actually need oil pressure for survival. The piston pins receive a healthy dose of oil, too, direct from the big ends up a hole running the length of the titanium conrod. Apart from the pistons and camshaft lobes (acting directly on the tops of the buckets), everything else, running on ball or roller bearings, can survive on just a light mist of oil every now and again.

Forget the engine for a moment and check out the suspension. Why has no one taken these theories as far before? Yes, yes, there’s nothing new with dual-wishbone girder forks or rearsuspension units in strange places. That’s not the point.

The degree of development is what I mean.

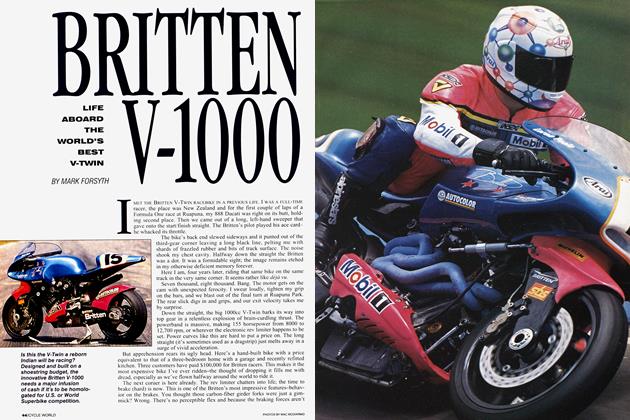

A wacky front end just for the hell of it is more common than you’d think.

There are a lot of frame builders around the world who blindly insist the telescopic fork is crap and then go and produce something that is infinitely worse than a good upside-downer-the Britten’s aerodynamic, carbon-fiber fork is better. It’s

much lighter than an upside-down fork, it is stiff in all planes, it has a blade-like frontal aspect and it’s capable of differentiating between bump and braking forces, something a tele-fork can’t do. All you can do with a tele-fork is fit progressively stiffer springs and dial in stiffer compression damping to combat braking forces. Britten’s girder fork will dive on the brakes, by an adjustable amount, but the team can get away with running very soft springs and damping because of the design.

Just to top this all off, the fork is adjustable in more ways than you can shake an Allen wrench at. Rake, trail, wishbone length and angles (mounted on eccentrics) are all movable. Even the front-wheel spindle and steering assemblies are mounted in eccentric bearing carriers. And while you’re looking at the picture of the front wheel, have a peek at the disc mounting points. Strong, light, simple and efficient. John Britten is justifiably proud of his fork design. It may have taken a couple of years to perfect, but the feedback from riders now has made it worth the effort.

The rear suspension is less revolutionary than the front setup but equally effective, equally adjustable and beautifully executed. The rear suspension unit (Öhlins, like the front) is placed ahead of the engine to get as much weight as far forward as possible.

So, why doesn’t Britten make this jewel of a bike roadworthy?

Cost, and lots of it. If you’re making very small volumes of extremely labor-intensive engines, then they’re going to be expensive. Make them cheap and you go out of business. Nice idea, though. A road-legal Britten? Yes, please, and leave the slicks on would you, old chap? -Mark Forsyth

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontOklahoma Hits Home

August 1995 By David Edwards -

Leanings

LeaningsGood Company

August 1995 By Peter Egan -

TDC

TDCThunder Bolts

August 1995 By Kevin Cameron -

Letters

LettersLetters

August 1995 -

Roundup

RoundupBritten To Build Indians

August 1995 By David Edwards -

Roundup

RoundupBikes Will Be Made In the Usa, Says Indian's New Chieftain

August 1995 By Alan Cathcart