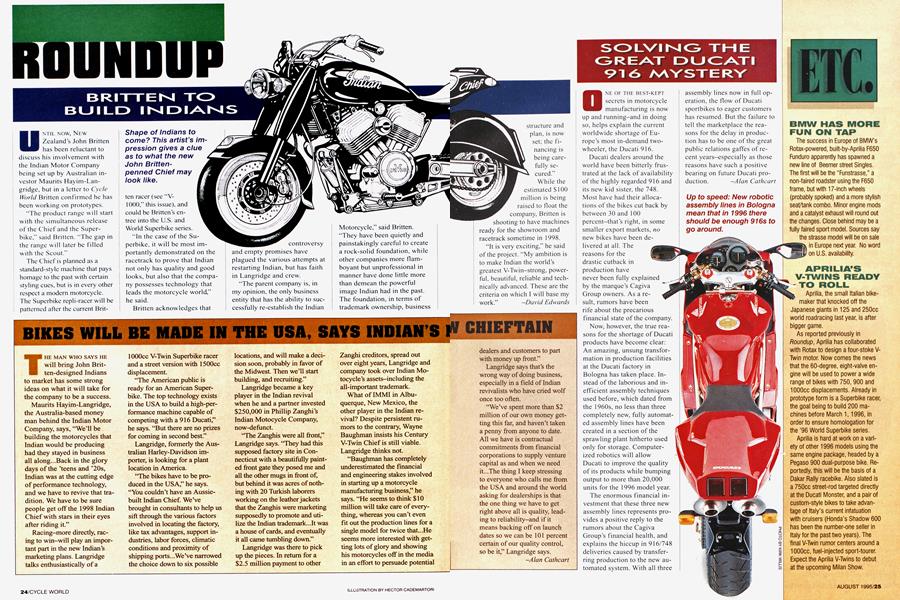

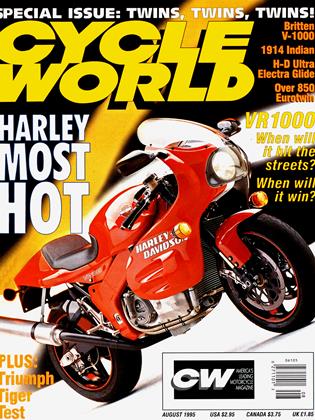

SOLVING THE GREAT DUCATI 916 MYSTERY

ONE OF THE BEST-KEPT secrets in motorcycle manufacturing is now up and running—and in doing so. helps explain the current worldwide shortage of Europe’s most in-demand two-wheeler, the Ducati 916.

Ducati dealers around the world have been bitterly frustrated at the lack of availability of the highly regarded 916 and its new kid sister, the 748.

Most have had their allocations of the bikes cut back by between 30 and 100 percent-that’s right, in some smaller export markets, no new bikes have been delivered at all. The reasons for the drastic cutback in production have never been fully explained by the marque’s Cagiva Group owners. As a result, rumors have been rife about the precarious financial state of the company.

Now, however, the true reasons for the shortage of Ducati products have become clear; An amazing, unsung transformation in production facilities at the Ducati factory in Bologna has taken place. Instead of the laborious and inefficient assembly techniques used before, which dated from the 1960s, no less than three completely new, fully automated assembly lines have been created in a section of the sprawling plant hitherto used only for storage. Computerized robotics will allow Ducati to improve the quality of its products while bumping output to more than 20.000 units for the 1996 model year.

The enormous financial investment that these three new assembly lines represents provides a positive reply to the rumors about the Cagiva Group’s financial health, and explains the hiccup in 916/748 deliveries caused by transferring production to the new automated system. With all three assembly lines now in full operation, the flow of Ducati sportbikes to eager customers has resumed. But the failure to tell the marketplace the reasons for the delay in production has to be one of the great public relations gaffes of recent years-espccially as those reasons have such a positive bearing on future Ducati production. -Alan Cathcart

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontOklahoma Hits Home

August 1995 By David Edwards -

Leanings

LeaningsGood Company

August 1995 By Peter Egan -

TDC

TDCThunder Bolts

August 1995 By Kevin Cameron -

Letters

LettersLetters

August 1995 -

Roundup

RoundupBritten To Build Indians

August 1995 By David Edwards -

Roundup

RoundupBikes Will Be Made In the Usa, Says Indian's New Chieftain

August 1995 By Alan Cathcart