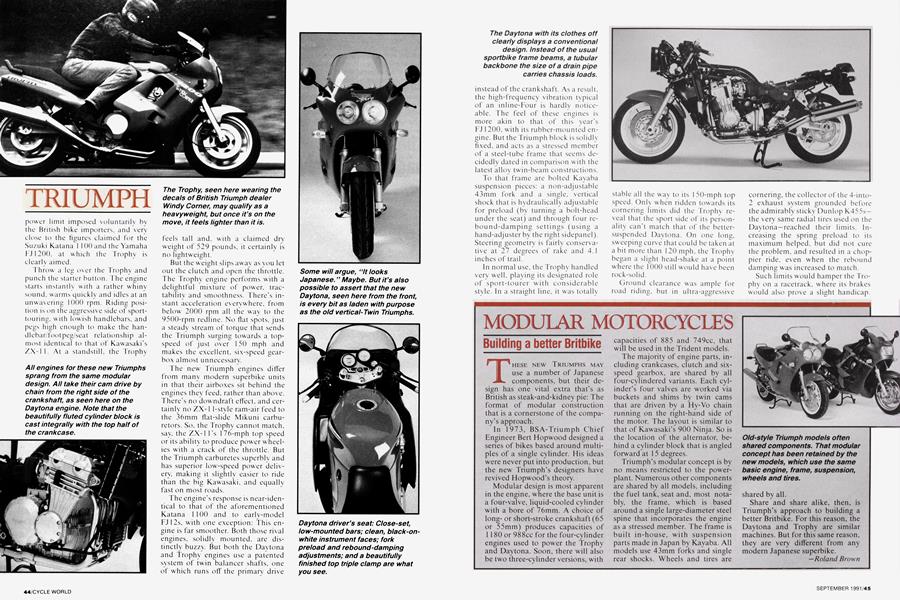

MODULAR MOTORCYCLES

Building a better Britbike

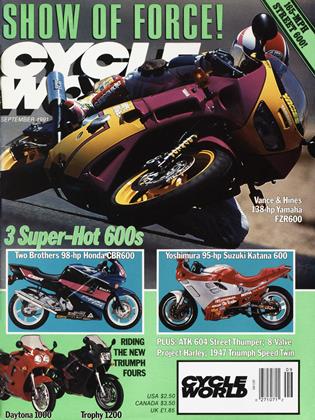

THESE NEW TRIUMPHS MAY use a number of Japanese components, but their design has one vital extra that’s as British as steak-and-kidney pie: The format of modular construction that is a cornerstone of the company’s approach.

In 1973, BSA-Triumph Chief Engineer Bert Hopwood designed a series of bikes based around multiples of a single cylinder. His ideas were never put into production, but the new Triumph's designers have revived Hopwood’s theory.

Modular design is most apparent in the engine, where the base unit is a four-valve, liquid-cooled cylinder with a bore of 76mm. A choice of longor short-stroke crankshaft (65 or 55mm) produces capacities of 1 1 80 or 988cc for the four-cylinder engines used to power the Trophy and Daytona. Soon, there will also be two three-cylinder versions, with capacities of 885 and 749cc, that will be used in the Trident models.

The majority of engine parts, including crankcases, clutch and sixspeed gearbox, are shared by all four-cylindered variants. Each cylinder's four valves are worked via buckets and shims by twin cams that are driven by a Hy-Vo chain running on the right-hand side of the motor. The layout is similar to that of Kawasaki’s 900 Ninja. So is the location of the alternator, behind a cylinder block that is angled forward at 1 5 degrees.

Triumph’s modular concept is by no means restricted to the powerplant. Numerous other components are shared by all models, including the fuel tank, seat and. most notably, the frame, which is based around a single large-diameter steel spine that incorporates the engine as a stressed member. The frame is built in-house, with suspension parts made in Japan by Kayaba. All models use 43mm forks and single rear shocks. Wheels and tires are shared by all.

Share and share alike, then, is Triumph’s approach to building a better Britbike. For this reason, the Daytona and Trophy are similar machines. But for this same reason, they are very different from any modern Japanese superbike.

—Roland Brown

View Full Issue

View Full Issue