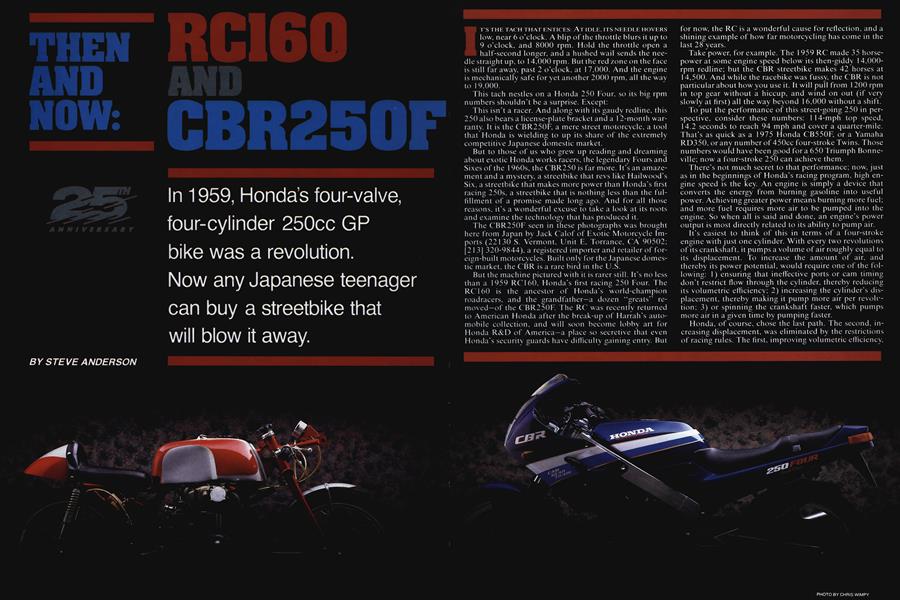

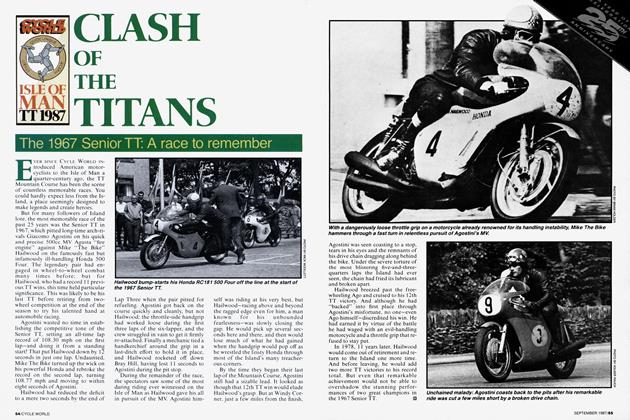

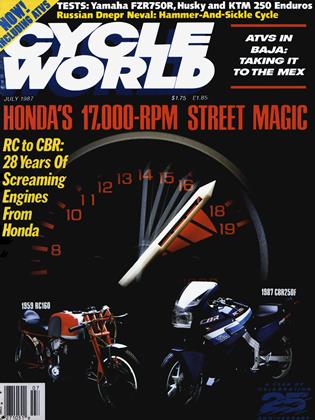

THEN AND NOW: RC160 AND CBR250F

In 1959, Honda’s four-valve, four-cylinder 250cc GP bike was a revolution. Now any Japanese teenager can buy a streetbike that will blow it away.

STEVE ANDERSON

IT'S THE TACH THAT ENTICES: AT IDLE, ITS NEEDLE HOVERS low, near 6 o'clock. A blip of the throttle blurs it up to 9 o'clock, and 8000 rpm. Hold the throttle open a half-second longer, and a hushed wail sends the needle straight up, to 14,000 rpm. But the red zone on the face is still far away, past 2 o’clock, at 17,000. And the engine is mechanically safe for yet another 2000 rpm, all the way to 19.000.

This tach nestles on a Honda 250 Four, so its big rpm numbers shouldn't be a surprise. Except:

This isn't a racer. And along with its gaudy redline, this 250 also bears a license-plate bracket and a 12-month warranty. It is the CBR250F, a mere street motorcycle, a tool that Honda is wielding to up its share of the extremely competitive Japanese domestic market.

But to those of us who grew up reading and dreaming about exotic Honda works racers, the legendary Fours and Sixes of the 1960s, the CBR250 is far more. It's an amazement and a mystery, a streetbike that revs like Hailwood's Six, a streetbike that makes more power than Honda’s first racing 250s, a streetbike that is nothing less than the fulfillment of a promise made long ago. And for all those reasons, it's a wonderful excuse to take a look at its roots and examine the technology that has produced it.

The CBR250F seen in these photographs was brought here from Japan by Jack Calof of Exotic Motorcycle Imports (22130 S. Vermont, Unit E. Torrance, CA 90502; [2 I 3] 320-9844), a registered importer and retailer of foreign-built motorcycles. Built only for the Japanese domestic market, the CBR is a rare bird in the U.S.

But the machine pictured with it is rarer still. It's no less than a 1959 RC160. Honda's first racing 250 Four. The RC160 is the ancestor of Honda's world-champion roadracers, and the grandfather—a dozen “greats” removed—of the CBR250F. The RC was recently returned to American Honda after the break-up of Harrah's automobile collection, and will soon become lobby art for Honda R&D of America—a place so secretive that even Honda's security guards have difficulty gaining entry. But for now, the RC is a wonderful cause for reflection, and a shining example of how far motorcycling has come in the last 28 years.

Take power, for example. The 1959 RC made 35 horsepower at some engine speed below its then-giddy 14,000rpm redline; but the CBR streetbike makes 42 horses at 14,500. And while the racebike was fussy, the CBR is not particular about how you use it. It will pull from 1200 rpm in top gear without a hiccup, and wind on out (if very slowly at first) all the way beyond 16,000 without a shift.

To put the performance of this street-going 250 in perspective, consider these numbers: 1 14-mph top speed, 14.2 seconds to reach 94 mph and cover a quarter-mile. That’s as quick as a 1975 Honda CB550F, or a Yamaha RD350, or any number of 450cc four-stroke Twins. Those numbers would have been good for a 650 Triumph Bonneville; now a four-stroke 250 can achieve them.

There’s not much secret to that performance; now, just as in the beginnings of Honda’s racing program, high engine speed is the key. An engine is simply a device that converts the energy from burning gasoline into useful power. Achieving greater power means burning more fuel; and more fuel requires more air to be pumped into the engine. So when all is said and done, an engine’s power output is most directly related to its ability to pump air.

It's easiest to think of this in terms of a four-stroke engine with just one cylinder. With every two revolutions of its crankshaft, it pumps a volume of air roughly equal to its displacement. To increase the amount of air, and thereby its power potential, would require one of the following; 1) ensuring that ineffective ports or cam timing don’t restrict flow through the cylinder, thereby reducing its volumetric efficiency; 2) increasing the cylinder’s displacement, thereby making it pump more air per revolution; 3) or spinning the crankshaft faster, which pumps more air in a given time by pumping faster.

Honda, of course, chose the last path. The second, increasing displacement, was eliminated by the restrictions of racing rules. The first, improving volumetric efficiency, was a course of decreasing gains: Once a normally aspirated engine is breathing reasonably well, the only improvements that can be made involve low-level supercharging through inertial and resonant tuning of the intake and exhaust systems. Over-reliance on such effects can dramatically narrow an engine’s powerband; and even then, there are limits on the amount of additional air that can be passed through a normally aspirated engine. No, increasing engine speed was the key, the only method that had no theoretical upper limit.

But that was just theory, and Honda had to put it into subtle practice, to translate it into steel and aluminum that could win races, and championships. Easier said than done; there are physical limits on how fast an engine can turn, limits to the loads that can be incurred before pistons crack, rings flutter, bearings fail, rods stretch. In the midFifties, valve gear was a particular problem, one that Mercedes and Ducati designed their desmodromic race engines to overcome.

But Honda’s road was different. Rather than attack the stresses of high-speed operation most directly with improved materials or more sophisticated components, Honda took an engineering approach that can best be described as radically conservative. Instead of making components that could withstand greater stresses, Honda avoided such high stresses through the use of multiple cylinders and four-valve heads. By dividing its 250cc between four cylinders, a machine such as the RC 160 could use such a short stroke (41 mm) and light pistons that high operating speeds wouldn’t entail inventing all-new reciprocating components; in that way, fairly conventional designs and 1959-era materials could withstand 14,000 rpm.

The same held true for the valve train: Four small, light valves could be controlled by conservative-technology springs ever so much easier than could two big, heavy valves. By miniaturizing engine components, Honda simply finessed many of the problems of high-speed operation.

But that makes it sound easy. It wasn’t, as the history of the RC 160 shows. This, the first Honda Four, contains all the key points of Honda’s winning architecture, but not in the refined form eventually achieved. Like the later Honda racers, the RC160 used an all-roller-bearing, pressedtogether crankshaft. Different, though is the cam drive; a Ducati-style tower shaft on the right side of the engine drives gears in the cylinder head that turn both camshafts. This was the last time Honda would use that design.

The cylinder head is more Honda standard: Twin camshafts open four valves through cylindrical tappets (resting in separate brass tappet blocks) completely above the valves and springs. The valves are adjusted by grinding the tappets to length. As with most early Honda racers, the cylinder head has a pentroof contour created by the approximately 60-degree angle between the intake and exhaust valves. The piston has a matching trapezoidal peak; with a relatively mild, 10.5:1 compression ratio, the resulting combustion space and centrally mounted sparkplug ensured that combustion could keep up with engine speed all the way to 14,000 rpm. But all this hardware created a bulky, heavy package: The RC160 engine was claimed to weigh 128 pounds complete.

Later Honda 250 Fours kept the basics, but in refined and shrunken packages. Six months after the first RC160 was raced, it was replaced by an all-new and far more modern-appearing machine, the RC161. Gone was the bevel drive to the cams, replaced by a centrally mounted geartrain. The cylinders were inclined 35 degrees, to supply the cylinder-head crown with much-needed cooling air. Carburetion was nearly downdraft, and the engine was narrow, with no crankshaft profusions beyond the outer main bearings. Refinements brought the power up to 38 horsepower at 13,000 rpm; by the end of that first season of GP racing, development had bumped the power to 40 bhp. But even that wasn’t enough. Within a year, the RC 161 gave way to another all-new design, the RC 162. It made a solid 42 bhp at 14,000 rpm—and was the first of Honda’s 250 racers to have made as much power as this year’s CBR250F streetbike.

But for all Honda’s success, there were limitations. With an air-cooled engine, keeping the cylinder-head crown cool was a particular problem. To keep the crown exposed to cooling air meant keeping the valves spaced fairly widely; 60 degrees between intake and exhaust valves was pretty much the minimum. Otherwise, a hot spot would develop on the crown between the too-closely spaced camshafts. The wide included valve-angle created a fairly tall combustion chamber, but one that worked adequately with the nearly square bore-and-stroke dimensions Honda was using for its racebikes (44mm bore and 41mm stroke for the 250 Fours).

With the piston and ring technology of the early 1960s, that 41mm stroke limited engine speed to something not far above the 14,000-rpm power peak of the RC162. To make the next big jump in engine power (one that was forced by the ever-faster two-stroke GP bikes of Yamaha) would require engine speeds of 17,000 rpm and above, and a stroke of less than 35mm.

That put Honda in quite a dilemma. A Four with those capabilities would need approximately a 47.5mm bore and a 35mm stroke, and that was too oversquare, given Honda’s combustion-chamber design. With the bigger bore, the piston crown would have to grow and fill more of the combustion chamber to maintain compression ratio, and the end result would be a combustion space that looked like the rind of a grapefruit. This narrow space wouldn't let fuel burn quickly enough for high efficiency and power.

Honda’s answer to this was consistent with all the company’s work in the 1960s: Don’t muck about with a proven cylinder-head design. Instead, scale it down and add cylinders. The result was the 250 Six with a 39.5mm bore and a 34.5mm stroke, an engine that was safe to 19,000 rpm and, by the end of its development in 1 967, was producing 66 horsepower at 18,000 rpm.

But today’s CBR250F poses another answer, one that came first from automobile racing and Cosworth Engineering, and found its way into Honda race engines only in the late 1970s. As valve-spring materials and design improved, oversquare engine dimensions became attractive, with bore-to-stroke ratios of 1.33:1 or even 1.5:1 striking the proper balance between piston and valve stresses. (The comparatively short stroke of an oversquare engine reduces piston loads at higher rpm, but the larger valves that fit in the bigger bore have to work harder. The right bore-to-stroke ratio balances the loads on the two components so they approach their strength limits at about the same rpm. This ideal ratio evolves as advances are made in either piston-and-ring or valve-train technology.)

Automobile racing engines solved the combustion problems of oversquare engines with narrower angles between the valves, pulling the combustion chamber down from a high-arched pentroof to a very shallow one. Compression ratios could then be maintained even with flat-top pistons; any cooling problems were minimized by liquid-cooling.

Oversquare engines with these compact, quick-burning chambers significantly increased power for any given displacement and number of cylinders.

Thus, the CBR250F closely mirrors car-racing practice. Honda set the bore at 48.5mm, the stroke at an extremely short 33.8mm—that’s less than \3/s inches, shorter even than on Honda’s 250 Six. The valves have been pulled together until they’re only 38.5 degrees apart, and a 1 1:0 compression ratio is possible without too tall a piston crown. The cylinder head and cylinders both are waterjacketed, so hot spots are effectively quenched.

Those are the basics. But the CBR250 engine also has stunningly beautiful details. Unlike any other current Honda engine, the CBR uses bucket tappets, with adjustment shims underneath. The tappets and shims are featherweights, adding only four tenths ofan ounce of reciprocating mass to each valve. The cams are gear-driven, and creatively, at that. A single gear on the crank, between cylinders three and four, drives the large clutch gear, and a gear train extends from there up to the camshafts. Because the cam drive comes up from the back of the cylinders, not as much additional distance between cylinders three and four is needed as there would be if the gearset were driven directly from the crank. Only % of an inch of cylinderblock width can be attributed to the the gear train.

As on the 1960 RC161, the cylinders of the CBR are inclined 35 degrees, and nearly straight ports are fed by downdraft carburetors. These CV Keihins provide the type of precise carburetion over a wide speed range that was inconceivable two decades ago.

But as superb as the visible details of the CBR250F are, however, some of the invisible ones are even more vital. All of Honda’s GP machines of the 1960s used roller bearings throughout their crankshaft; the CBR uses none. It instead depends on high-technology plain bearings, and impressive manufacturing technology to maintain the tolerances to allow them to work. As plain bearings shrink, their clearances must also, all while their surface finishes must improve. Maintaining the dimensional accuracy to make such a crankshaft work is no problem in the one-off world of the racing shop, but to achieve that in an engine produced in the tens of thousands, fora reasonable price, is a greater achievement.

In the end, that is perhaps the most important fact: While the CBR manifests Honda’s best knowledge of engine design, it can only be built because of advances in manufacturing technology over the last 25 years. Tolerances that could once be held only by a skilled machinist are now routinely met by automatic machining centers. High-strength materials that once were used mainly by the aerospace industry have seen their specifications met by standard production items. Advances in casting technology produce parts that simply weren’t possible 25 years ago. The end result is that the CBR, with mild retuning for racing, could defeat any four-stroke 250 GP bike Honda ever fielded, yet it’s available to any Japanese teenager.

And even that is just the beginning. The CBR250F was superseded only last month by the CBR250R Hurricane, an update that yields three more horsepower and raises the redline to 18,000. And Honda is openly hinting that this year’s Tokyo show may see a streetbike that spins all the way to 20,000 rpm, and raises the power-production standard to over 200 horsepower per liter.

The wave of four-stroke engine technology that washed over the racing world in the 1960s is currently sweeping over the streets. And it will produce motorcycles the likes of which we’ve seen only in our dreams.

View Full Issue

View Full Issue

More From This Issue

-

Editorial

EditorialCbs, Abc & Cpsc Vs. Atvs: Bs On Tv

July 1987 By Paul Dean -

At Large

At LargeOld Guys, Rockers And Rockets

July 1987 By Steven L. Thompson -

Departments

DepartmentsLetters

July 1987 -

Roundup

RoundupCpsc Vs. Atvs: Chronology of A Crisis

July 1987 -

Roundup

RoundupSuzuki: Stayin' Alive With the Samurai

July 1987 -

Roundup

RoundupLetter From Japan

July 1987 By Kengo Yagawa