SERVICE

Bad gas and injectors

Bad gas has been a problem on a trip we’ve just completed of the Northwestern U.S. and Canada. Our Gold Wing Limited sputters and dies every time we forget and tank-up on no-brand gas (at the convenience gasoline/snack stores). It refuses to fire until we drain the “bad” gas and replace it with a brand name. We haven’t heard of anyone else having this problem.

Could it be low octane, high water content, or the snubby computerized injectors on the Limited or Aspencade SE-i? James and Glenna King Shiprock, New Mexico

No, this certainly isn 7 a common problem, but it's probably related to high alcohol and water content of a few no-name gasolines. The manufac-

turers of some unbranded gasolines recently have resorted to alcohol additions to boost octane, which has made these fuels more sensitive to moisture absorption and the separation of a alcohol /water mixture from the gasoline. It's only speculation, but perhaps

the Gold Wing Limited's injection .ST.Vtem is less able to pass small amounts of unburnable mixture than carburetors might.

In any case, the easiest cure is to buy gasoline brands that work in your bike, and stay away from alcohol blends. Fortunately, more and more states are requiring the posting of alcohol content on fuel pumps.

True crankshafts

There is a lot of talk about rollerbearing crankshafts being out of true, and Eve heard that on a modified engine they should be straightened and strengthened.

What about plain-bearing engines like my GS750EZ?

Also, I know the difference between horsepower and torque, but what is felt during acceleration? Eric Liedtke Cedar Rapids, Iowa

Roller-bearing cranks are assembled by pressing flywheels and pin sections together. Consequently, it is possible to assemble a crank so that all mainbearing diameters don 7 share a common center; or so that the phasing of one rod journal to another is incorrect. These conditions are described as being “out of true. "Also, if sufficiently large twisting forces are applied to a roller-bearing crank (perhaps by a hard downshift or a drag strip launch), the pressed-together joints can slip, leaving even a good crank out of true.

These problems are not common on street-ridden engines (though a good crankbuilder might be able to tweak a production crankshaft to a state closer to true than it comes from the factory, and thus reduce vibration), but they plague highly hot-rodded drag-racing motors based on Kawasaki Z-ls or Suzuki GSl 100 or 1150s. The solution the drag-racing world has applied is to true the cranks, then weld the crankpins at the press joints to keep everything in place.

None of this applies to plain-bearing crankshafts. They're machined from a single hunk of metal, and as long as they're made true, they stay true. So there's really no need to do anything with the crank on your GS75Ö.

As far as what you feel during acceleration, it's simply that— acceleration, and could be expressed as a g force, perhaps .8 g on a big motorcycle at low speeds. But because acceleration is directly proportional to torque in any given gear, looking at a torque curve will tell you a lot about how a motorcycle will feel when ridden. A machine with a flat torque curve will accelerate very smoothly and evenly, w hereas a bike w hose torque curve has big jumps in it w ill have equally big jumps in acceleration, and should feel peaky. But because people are better at perceiving changes in acceleration than they are at accurately gauging its value, they often guess that a machine that accelerates smoothly is slower than the peaky machine, when a dragstrip might prove otherwise.

One cable or two?

Are there any advantages in having dual throttle cables? Some bikes have two, others have just one.

What is the reason for two? Todd Felmly Deerfield, Ohio

Bikes with two throttle cables generally use them in a push-pull arrangement: When one cable is pulling the carb slides or butterflies open, the other is pushing. Then w hen the throttle is closed, the roles reverse, and the cable that was pushing now pulls the slides or butterflies closed. Because cables can transmit much more load when pulling than when pushing, this helps ensure that the twistgrip can alw'ays override a sticking carburetor, and always shut the power down. In contrast, a bike w ith a single throttle cable relies more on the carburetor return spring to close a slide or butterfly. The two-cable arrangement is simply insurance against a sticking throttle, and may allow' the use of lighter return springs that reduce throttle effort. 0

View Full Issue

View Full Issue

More From This Issue

-

Editorial

EditorialIdol Speculation

December 1987 By Paul Dean -

At Large

At LargeService Bulletins

December 1987 By Steven L. Thompson -

Leanings

LeaningsDesmo Fever

December 1987 By Peter Egan -

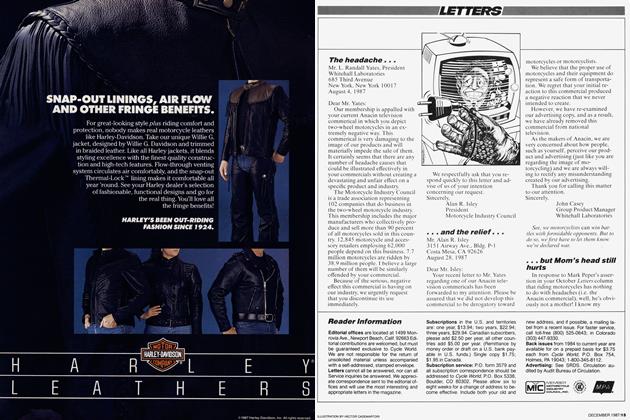

Letters

LettersLetters

December 1987 -

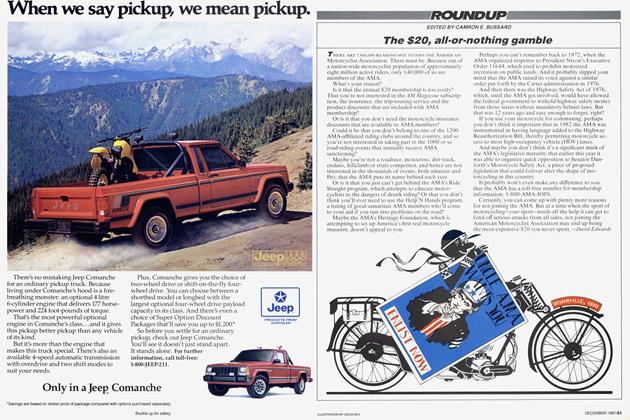

Roundup

RoundupThe $20, All-Or-Nothing Gamble

December 1987 By David Edwards -

Roundup

RoundupRallying In the Rockies

December 1987 By Bill Stermer