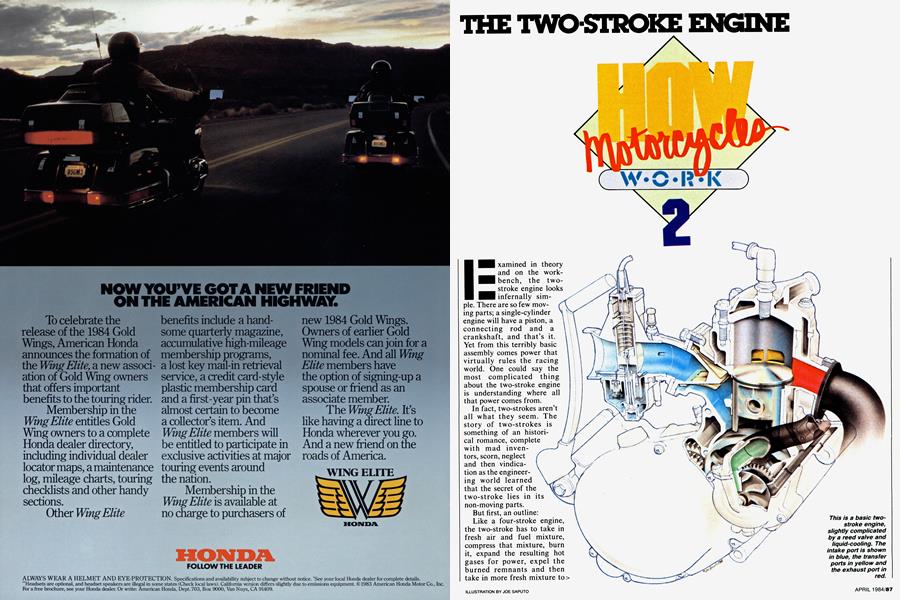

HOW MOTORCYCLE W·O·R·K 2

THE TWO-STROKE ENGINE

Examined in theory and on the work-bench, the two-stroke engine looks infernally simple. There are so few moving parts; a single-cylinder engine will have a piston, a connecting rod and a crankshaft, and that’s it. Yet from this terribly basic assembly comes power that virtually rules the racing world. One could say the most complicated thing about the two-stroke engine is understanding where all that power comes from. In fact, two-strokes aren’t all what they seem. The story of two-strokes is something of an historical romance, complete with mad inventors, scorn, neglect and then vindication as the engineering world learned that the secret of the two-stroke lies in its non-moving parts.

But first, an outline: Like a four-stroke engine, the two-stroke has to take in fresh air and fuel mixture, compress that mixture, burn it, expand the resulting hot gases for power, expel the burned remnants and then take in more fresh mixture to> start the process again. The four-stroke does this one step at a time. It may take two crankshaft revolutions to complete a cycle, but at least it’s easy to follow. The twostroke, in contrast, is in a terrible rush. It crams all those steps into a single crankshaft revolution, one up-and-down piston movement. It does more than one thing at a time, so it’s harder to hold a mental picture of its operation.

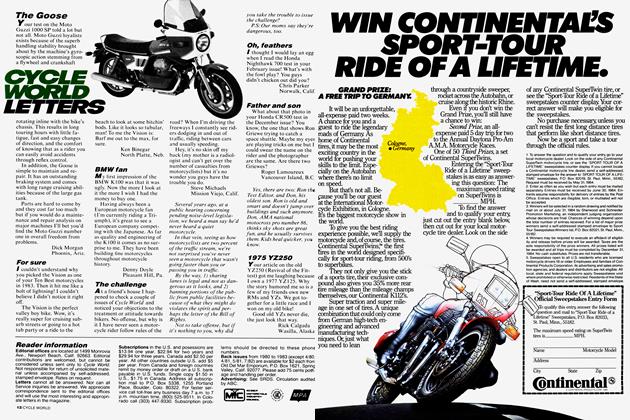

And we can’t even imagine these processes until we introduce at least some of the nonmoving parts:

They are called ports. They are — here’s that word

again—simply openings in the cylinder wall. Ignoring exceptions for the moment, our typical engine will have an exhaust port in the front of the cylinder, an intake port in the back and transfer ports at each side. Further, many engines have boost ports, generally adjacent to the transfer ports. All these ports do as their names imply.

Before getting to what happens when, we need to keep in mind that at least two things are happening at once. There’s activity above the piston and below the piston, at the same time and yes, it’s hard to keep two pictures in mind simultaneously.

Let’s start with the piston at top dead center and follow it through the 360° of one revolution, one complete cycle.

Every time a two-stroke’s piston arrives at TDC there is compressed fuel and air above the piston, and the spark plug has ignited this mixture. At TDC also, the piston skirt is covering the exhaust port and the transfer ports, while the intake port, usually lower in the cylinder, is uncovered and fresh charge has been flowing into the crankcase.

The burning fuel and air heats and expands. The piston is driven down the cylinder by this expansion. At some point, let’s say 100° of crankshaft rotation after TDC, the piston covers the intake port and the descending piston begins to compress the charge in the crankcase. The exhaust port is uncovered, so above the piston the expansion has lost its power, so to speak, and the exhaust gases begin to leave the cylinder via the exhaust port. Further down, the piston uncovers the transfer ports and that charge, under compression remember, rushes into the cylinder above the piston.

The crankshaft has made half a turn and the piston is at BDC. Within that half a turn, the two-stroke has performed the power stroke and the intake stroke which in the fourstroke requires two half-turns. (There’s a flaw in that logic, and you’ve already spotted it, but let it go for a moment.)

Now the piston begins moving back up. Below the piston, there’s a partial vacuum. The piston covers the transfer ports, sealing off the incoming charge. Next it covers the exhaust port. Above, we have compression of an unburned charge. Below, the intake port is uncovered and the partial vacuum in the crankcase is pulling fresh charge into the crankcase.

Ever wonder why some twostrokes have radical compression ratios and others have specifications more appropriate to a lawnmower? It’s because two-stroke compression ratios are reported in either of two ways: from the bottom of the stroke, the way it’s done with four-strokes, or from that point where the ports are covered and compression actually begins. Thus, the same engine might have a claimed c.r. of 6:1 or 10:1, depending on method.

And so, quicker than it takes to tell, the piston arrives again at TDC and this second half-turn has contained the exhaust stroke, well, the completion of the exhaust stroke, and the compression stroke.

Simple. Basic.

And so is the flaw. The power stroke wasn’t a full power stroke. It ended, more or less, when the exhaust port was uncovered. Likewise the intake stroke wasn’t a full stroke, the exhaust stroke ditto and compression didn’t really begin until halfway through the second half turn.

For many years after the invention of the two-stroke, this was accepted as the way things are. Two-strokes had fewer moving parts, i.e. they were cheaper to make. They developed less power than four-strokes and burned, wasted, actually, more fuel for that power. They were industrial engines or used only for the least-sporting, smallest, cheapest and smokiest of motorcycles. There were some exceptions, the most prominent being the Scott, an English machine that was not only a two-stroke, it was a Twin and it had water-cooling back in 1912. But the Scott was so different in that and other ways it wasn’t so much ahead of its time as it was apart from its time.

Anyway. For obscure reasons, while the Americans and English and Italians were inventing, discarding and rediscovering four-valve heads and twin overhead cams, several German firms began working on two-strokes. They did some really odd things, for example an engine with two cylinders except one pumped the mixture into the other, where combustion took place. And there was a Triple with two cylinders doing combustion and one serving as a pump. Some of these engines worked, many didn’t or weren’t worth the bother.

But they led to serious thought and experimentation.

The two-stroke limit was imposed by the crowding of its cycles. The exhaust wasn’t fully exhausted, for instance. And the incoming fresh charge kept right on going, in from the transfers and out the exhaust.

The two-stroke’s true believers worked out that if you aimed, shaped and sized the various ports, they could help each other. There were some experiments with piston crowns topped by ridges and dams; clumsy, but the idea was right. Then there were ports of all kinds in all sorts of places.

Most important of all was the exhaust. Whole books can be written (and have been written) about two-stroke exhaust tuning. We’ll cover exactly how this works later in this chapter. For now, in the history section, it should suffice that the exhaust gases are a compressible stream, a moving column of air.

Summing up years of achievement, it was seen that the sealed crankcase becomes a natural air pump and that proper porting helped the good air go in and the bad air go out, and that the correct exhaust ports, pipes and chambers literally emptied the cylinder by the effect of the exhaust’s own pressure waves. The overall result is that the engine gets more than full intake, compression and exhaust strokes, while all the potential of the expansion and force of the power stroke can be extracted while the expansion is going on.

This hard-won knowledge appeared first in road racing, used by such firms at MZ, in East Germany.

Here’s the romance and adventure. Totalitarian governments don’t like independent and creative thought of any sort. In capitalist countries, new and better ways to do things are worth their weight in, if not gold, then surely in salaries, stock options and company cars, never mind being free to travel.

So it was that men like Ernst Degner, a world class racer and a key engineer at MZ, escaped from the MZ team. He was picked up, in several senses of the word, by Suzuki. As they said in the Victorian novels, then All Was Known.

And the two-strokes took over the smaller GP classes, then all the classes. The twostrokes moved into motocross, then small road bikes, then middleweights.

The four-stroke crowd hurled abuse: Corn Popper! Ring-Ding! Killer Bee! and complained about fouled plugs and the mess of mixing gas and oil. But we all know the damage names can do.

Now two-strokes dominate the perfomance scene so completely that it’s hard to remember when they didn’t. It’s been almost 10 years since a Grand Prix was won by a four-stroke,and telling your average 16 year-old promotocrosser that four-strokes were once the hot set-up will get you nothing but a blank stare. Even performance twostroke street bikes are making a comeback in the pollution regulated United States: Yamaha is releasing a RZ350 with catalytic converters, and few doubt that the RD500 will follow it into the U.S. shortly.

And that’s the broad outline and the history lesson. Now that we know the principies, let’s go back and see how the modern two-stroke really works.

Most two-stroke power characteristics are related to the crowding of cycle events and the effects from piston controlled valving. Ports open and close symmetrically when piston controlled: if the intake port opens 75° before TDC, it’s going to close 75° after TDC. That’s not a problem on the way up, when crankcase volume is increasing, but think what it means on the way down, when the piston is compressing the charge: the intake port is still open with pressure rising in the crankcase. Why doesn’t the mixture in the crankcase flow right back out? At low engine speeds it does. As engine speeds increase, inertial and resonance effects come into jQ play, preventing in ^<^>stant flow reversal inthe intake tract.

<<^ The inertia effect is simple enough: the gas moving in the port has its own momentum, and takes time to come to a stop and change direction. The longer the port, the bigger the column of moving gas, and the longer it takes to change direction. Long ports can prevent flow reversals at low engine speeds, but they tend to restrict flow at high speeds.

The resonance effects result from air being elastic, capable of being compressed and springing back. Compression waves traveling through air are invisible, but you can see them in other materials. Take the case of a Slinky, the toy made from a coil of flat wire. Stretch it out so the coils are evenly spaced, and then give it a sharp push on one end. A little patch of closely spaced coils travels down the length of the Slinky, hits the far end, and then travels back. The same sort of waves happen in motorcycle ports and exhaust systems, but instead of compressed or expanded coils, the wave travels as a zone of low or high pressure air.

Back to the Slinky. Imagine that a compression wave takes five seconds to travel from one end, reflect off the far end, and come back. If you timed pushes (like the one that excited the first wave) so that you pushed five seconds apart, each additional push would reinforce the original wave. It would have more energy, as shown by closer coil spacing, and as shown by how hard it pushed on your hand at the far end. When the pushes and waves reinforce each other like this, they’re said to be in resonance.

How does this relate to air and engine ports? Pressure waves travel up and down ports, excited by the pressure changes in the crankcase or cylinder. If the port length is right, timing of waves and excitations will be matched, and the wave will pick up considerable energy, stored as pressure. Timed correctly in the intake port, a high pressure wave can arrive at the crankcase as the port is near closing. The wave balances the rising pressure created by the descending piston, preventing flow reversal and mixture loss. Unfortunately, this will occur only over a narrow range of engine speeds, and crankcase filling will be better at these speeds than at others.

Pressure pulse tuning is even more important in filling thee cylinder with the mixture from the crankcase. It starts when the exhaust port opens, and the hot, still relatively high pressure gas rushes out. After traveling down a short head pipe, it encounters an expanding cone, a diffuser. The gas at the front of the pulse expands and slows down, its pressure increasing. Back at the port itself, wave reflections have actually dropped the pressure to below atmospheric. As the gas travels down the exhaust system, it encounters a converging cone. This time a high pressure wave is reflected, traveling back toward the exhaust port.

The pressure at the exhaust port is the key. With the right exhaust system, the right engine speed, and the right port timing, the pressure there can be below atmospheric shortly after exhaust opening. The low pressure pulls remaining exhaust gases from the cylinder, and drops the pressure in the cylinder to assist pulling mixture up through the transfers as well. The, when the exhaust gases are scavenged from the cylinder and fresh charge is starting to be wasted out the port, a high pressure wave returns from the far end of the pipe and actually shoves mixture back into the cylinder. This is supercharging with no moving parts.

Similar things happen in four-stroke engines, but not to the same effect. Events are too separated in four-strokes for as much interaction between intake and exhaust to occur, and resonance tuning plays a lesser role. In a two-stroke, the energy dumped out the exhaust by the early opening of the exhaust port is put to positive use, and the exhaust pipe is as much a part of gas pumping as the piston is.

Resonance effects combine with the two-stroke cycle to make very powerful engines. Power is proportional to heat generated, which depends on fuel burned, which depends on air pumped. Two-strokes start with the advantage of pumping air through every revolution, not every other. They lose part of this advantage to inefficiencies encountered in crowding a complete cycle in a single crank revolution, and then they pick some of it back up through exhaust system supercharging. The end result is that a single cylinder twostroke race engine of a given size will put out 10-20 percent more power than a four-stroke of the same size. The twostroke won’t have to turn as fast to make its greater power, and, because of that and its simpler construction, it will weigh considerably less than the four-stroke.

The two-stroke’s disadvantages stem from the same sources as its strengths. Resonance tuning is only effective when engine speed matches up with the exhaust pipe or intake port characteristics. At lower or higher speeds, pressure waves may actually work against cylinder or crankcase filling, supplying just the wrong pressure at the wrong time. Good power is made only when everything is working together; two-strokes lack the smooth power curves that four-strokes can supply. Symmetrical port timing is partly to blame here as well. Early intake and exhaust port opening is required for high speed power, but that forces late closings that make the engine even more dependent on resonance tuning to prevent flow reversals. Fuel economy suffers at engine speeds other than peak because fresh charge is lost out the late closing exhaust port. This lost fuel appears in the exhaust as unburned hydrocarbons and is a chief cause of two-stroke engines’ bad pollution rating.

For most two-strokes through most of the present period, this has been dealt with in what looks to be straightforward fashion: porting.

When the professional tuners and the guys in the pits at the local motocross track say porting, they mean enlarging and moving the ports.

Two-strokes have valve timing, just as four-strokes do. As it happens, the lower the ports in a cylinder, the lower the engine speed at which all the inertial and resonance forces come into power. The exhaust system, with its cones and reverse cones, etc., works the same way.

Thus, back at the factory the designers work out the desired characteristics for, say, an enduro 250 or a motocross 125 or even the customer version of the 500 GP bike. The systems are matched; carb to work with exhaust, etc.

We’re dealing here with racing, be it professional or impromptu, which means nearly everybody involved wants more power.

The traditional technique has been to rework the ports. If the roof of the exhaust port is raised, the engine speed at which the engine cranks out peak power is also raised and so is peak power. The same goes for the shape and length of the exhaust pipe.

This used to be easy. There were pipe builders on every corner, while half the twostroke Bridgestone Twins on the road at any given time weren’t on the road, they were in the garage while their owners trimmed away on the disc valves.

Since those early days the factories have begun doing this for the owners, in effect. It’s difficult to get a lot more performance without seriously subtracting power at less than peak rpm.

And even with professional revision, what happens on the downstroke still controls what happens on the upstroke.

Overcoming these deficits has added complexity to the simple piston port engine. Low pressures and temperatures at the intake port have allowed the use of valving that allows non-symmetrical timing. Reed valves (fig. 2) placed in the intake tract act as simple check valves, opening with a small pressure drop to allow flow into the crankcase, closing as flow reverses. They may be used to tame the low speed behavior of engines with intake port timing biased toward high speed operation; at low speeds the reed valve may close the port shortly after TDC, even though the piston doesn’t cover it for another 80 or 90°. Once reed valves were used in twostrokes, tuners exercised their ingenuity in thinking of further uses for them. One was feeding a boost port, connecting the intake tract directly with the cylinder and allowing exhaust pipe suction to bypass the crankcase and pull mixture directly from the carburetor. Another was using the reed valve to connect the crankcase directly with the carburetor with no piston interference whatsoever. This type is known as a case reed, and leaves intake timing dependent solely on the pressure drop across the reed valve and on how quickly the reed valve can react. Reed valve motors didn’t offer more power than piston port motors, but they offered a better power spread with improved low speed running.

Another valving that allows asymmetrical timing is the disc valve. A port leading directly to the crankcase is controlled by a flat, partially cutaway, disc (fig. 3). The disc is driven at engine speed, and the port opens and closes as the cutaway portion passes over it. Timing is constant, and differs considerably from that used in piston port engines. A piston port road race engine may open its intake 100° before TDC, and close it 100° afterwards. A disc valve engine making the same peak power could use an intake opening earlier, at 135° before TDC, and closing earlier as well, at 65° after TDC. With the earlier closing, less mixture escapes out the inlet at low speeds. The disc valve engine benefits by having a better power spread than the piston port, and, because the disc valve is less restrictive to high speed flow than reed valves, disc valve engines can make more peak power than reed valve engines.

If only the same approaches could be used on the exhaust port ... Unfortunately, the high 9^|, temperatures and pressures there have prevented anything but piston controlled valving to be used. That leaves symmetrical exhaust timing, but there have been some creative approaches to broadening the powerband with exhaust modifications. One is the Yamaha power valve. It moves to obscure the top of the exhaust port at low engine speeds, effectively reducing exhaust timing. At low speeds, the exhaust timing looks like it belongs on a water pump engine working in some farmer’s field. At high speeds the power valve unblocks the port,and the exhaust appears more appropriate for a road race engine. The best of both worlds appears possible: power down low like a trials engine, power up high like a road racer. Unfortunately, reality is less than the promise, but the power valve does offer a broader power spread than would otherwise be possible.

Another approach is to change the resonant frequency of the exhaust pipe as engine speed changes so the engine and exhaust pipe stay in better tune. Go-karists lead the way here, using tromboning expansion chambers with movable cones, all controlled by cables and a hand lever. Moving the rear cone aft can delay the return of the high pressure wave, making the pipe more effective at a lower engine speed. Telescoping the head pipe can shift all pipe resonances one way or another. The most sophisticated kart engines use pipes that move several cones at once, and by proportional amounts. All this movement is still controlled by hand, but there are definite possibilities here for motorcycles. Fastacting electric motors could tune an expansion chamber to respond to an engine's needs, and considerably broaden power.

If that’s a little beyond present practice, another kart technique has found application in 1984. Years ago it was discovered that a hole drilled in the head pipe of an expansion chamber would drop the speed where the engine made the most pow'er. If you controlled this hole with a simple valve, you could exit a slow corner with the hole open, and with the power peak down closer to where the engine was operating. When the kart and engine picked up speed on the straight, the hole could be closed, boosting high speed power. This is essentially Honda’s ATAC system, but now the hole is opened and shut automatically, and connects to an enclosed chamber instead of the atmosphere. Like Yamaha’s power valve, it isn't the sole answer, but all indication is that it has been effective in broadening power on the new Honda CRs.

The same principle works, to some degree, on the intake side. Yamaha came up with what could be called a shock absorber for air waves. There's an opening in the pipe between carb and intake port. A hose runs from this hole to a small chamber, which looks like a bottle and has come to be called just that, a boost bottle.

When the resonance of the incoming air waves are right, they skip right over this hole. But, remember we mentioned that the pressure waves could be exactly wrong, could interfere with and block the incoming charge? Those negative waves bounce olT the intake tract walls. But with the opening, the waves don't bounce. Instead they go up the hose and into the chamber, where they are stored. Like the power valve, it doesnot work as well on the track as it does in the brochure, but it does work. The characteristics of the two-stroke’s cycle have shaped its mechanical design as thoroughly as they’ve shaped the power spread. With crankcase pumping, four-stroke style lubrication with oil sloshing about the crankcase isn't feasible. Instead, ball and roller bearings, with only small oil requirements, are used on crankshaft and connecting rod. Oil is supplied as a mist, carried in with the fresh fuel/air charge in most engines. (Some twostrokes have used pumps that meter precise amounts of oil directly to the bearings, but this practice hasn’t been generally adopted because the simpler mist approach is both adequate and cheaper.) The lubricating oil may have been mixed with fuel, and be carried in with it through the carburetor. Or it may have been injected into the intake tract by a pump, with the amount varying with engine speed and th rot tie position. In either case, its fate is the same: it's carried through the crankcase with the air/fuel mixture, passed through the combustion process, and ejected out the exhaust. The characteristic blue fog left in a twostroke’s wake is the remains of oil condensing in the relative cool of the surrounding air.

Using the crankcase as a pump housing also controls engine configuration. Every cylinder of a two-stroke has to have its own crankcase. That’s no problem for an inline engine or a square Four, because those designs have a crankshaft throw for each cylinder.

But traditional, read fourstroke, Vees share crankpins and perforce share the crankcase as well. Thus, the current Yamaha V-Four GP engine isn’t the Vee we’re used to. Instead, it's a pair of side-byside Twins with their barrels leaned away from each other and their separate cranks geared together. The V-Three Honda GP engine is more like an inline Triple with the center cylinder leaned 90° away from the other two.

There are two-stroke Vees with shared crankpins. Some outboard engines have extra long crankpins and a rotating seal that divides the crankcase so each cylinder has its own independent crankcase volume to use as a pump.

Combustion occuring every engine revolution places higher thermal loads on twostrokes than four-strokes. The piston, directly exposed to combustion temperatures, bears the brunt of the thermal fight. The piston crown may run at average temperatures in excess of 500° F, well above the point where most aluminum alloys have any longterm strength. High temperatures limited performance of early two-strokes so much that in the 1950s, four-stroke superiority went largely unquestioned. As improvements were made in the early 1960s, that power superiority was threatened, but only in small cylinder sizes. Everyone knew that you couldn’t make, say, a 500cc twin cylinder and expect it to run without continual piston seizures.

Well, almost everyone. In 1967 Suzuki released the 500cc Titan, the two-stroke Twin that broke all the rules, and not only did it not seize, it ran and ran. What allowed a machine like this to be built was improved piston materials. Aluminum alloys were developed during the 1960s that contained upwards of 20 percent silicon. They offered superior high temperature strength, and more important, they expanded less as they heated up. Piston to cylinder fit could be better controlled, and the piston could transfer more heat to the relatively cool cylinder wall. Piston ring seal was improved by the steadier platform provided by the close fitting piston, so there was less hot blow-by to heat up the piston as well.

Even with exotic materials, though, piston temperatures can be a problem. Some aircooled machines alleviate the problem by running rich fuel/air mixtures. The evaporation of the excess gasoline drops operating temperaturesalbeit at the expense of power and fuel economy. Watercooling is another answer, and it became common on racing two-strokes in the 1960s. With water-cooling, engine temperatures can be more uniform and controlled, which in turn allows closer control of the piston-cylinder fit when the engine is running. Once again, a piston in closer proximity to the cool cylinder walls can rid itself of more heat.

There’s a power advantage to water-cooling beyond the leaner mixtures the engine will tolerate. Mixture entering a two-stroke travels a long path, with substantial exposure to hot metal surfaces. It picks up heat from these surfaces, and loses in density as a result. The warm mixture that finally arrives in the cylinder contains less air than it would if it were cooler. Anything that drops the temperature of the engine structure or isolates the air from hot surfaces will increase charge density and power. Water-cooling does this well enough to give 10 to 15 percent more power than from an equivalent aircooled engine. Even at that, improved isolation of the fresh charge from heat offers the promise of greater power in future engines.

If two-stroke engines have evolved away from cheap and nasty devices fit only to be used in the most basic of vehicles to engines that set performance standards, much of it is due to unseen details. Current engine oils look much like the oils in use 20 years ago, but they provide much better lubrication while not gumming up piston rings and pistons. Carburetors haven’t changed in appearance much, but current examples provide much finer control of mixture. That can be especially important for good throttle response in any engine. Ignitions hide under gas tanks, but plug fouling is a rarity in modern twostrokes, instead of the regular event that kept the Bultaco rider's jacket pockets stuffed with fresh plugs and a plug wrench.

Greater power over a wider range from future two-strokes is assured as increased understanding of the engine processes develops. The original Honda 250 Elsinore made less than 30 bhp at the rear wheel; the current version, 10 years later, makes 30 percent more with a better powerband. Even the RZ350, with its exhaust catalyst and emission controls, makes substantially more power than the RD350 of a decade ago. This will continue, and the simple twostroke will grow more and more complex as more valves and engine controls are added and catalytic converters tacked on. But the result will be more power everyplace, and with more civility. That’s difficult to argue with. ®

View Full Issue

View Full Issue