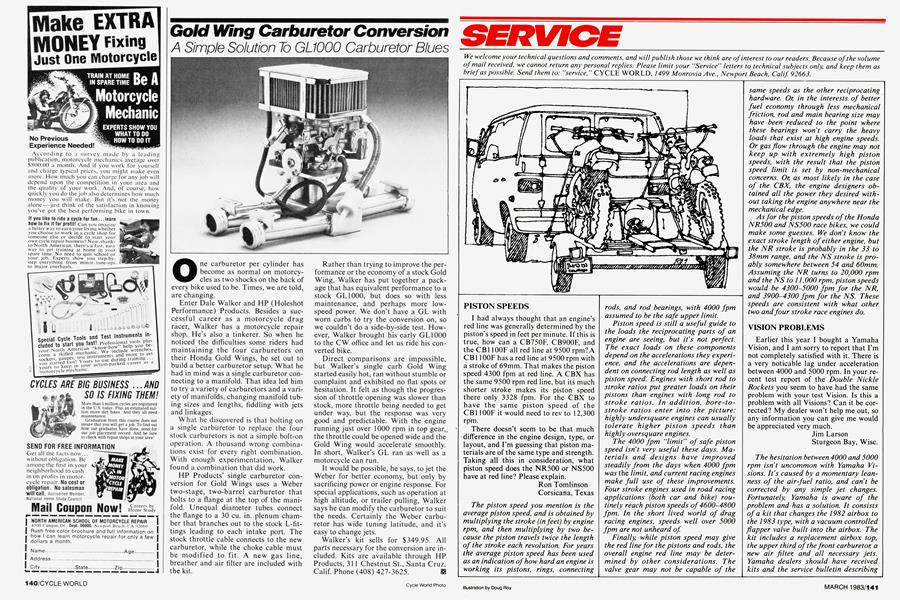

SERVICE

We welcome your technical questions and comments, and will publish those we think are of interest to our readers. Because of the volume of mail received, we cannot return any personal replies. Please limit your “Service” letters to technical subjects only, and keep them as brief as possible. Send them to: “service,” CYCLE WORLD, 1499 Monrovia Ave., Newport Beach, Calif. 92663.

PISTON SPEEDS

I had always thought that an engine’s red line was generally determined by the piston’s speed in feet per minute. If this is true, how can a CB750F, CB900F, and the CB1100F all red line at 9500 rpm?A CB 11 OOF has a red line at 9500 rpm with a stroke of 69mm. That makes the piston speed 4300 fpm at red line. A CBX has the same 9500 rpm red line, but its much shorter stroke makes its piston speed there only 3328 fpm. For the CBX to have the same piston speed of the CB1100F it would need to rev to 12,300 rpm.

There doesn’t seem to be that much difference in the engine design, type, or layout, and I’m guessing that piston materials are of the same type and strength. Taking all this in consideration, what piston speed does the NR500 or NS500 have at red line? Please explain.

Ron Tomlinson Corsicana, Texas

The piston speed you mention is the average piston speed, and is obtained by multiplying the stroke (in feet) by engine rpm, and then multiplying by two because the piston travels twice the length of the stroke each revolution. For years the average piston speed has been used as an indication of how hard an engine is working its pistons, rings, connecting

rods, and rod bearings, with 4000 fpm assumed to be the safe upper limit.

Piston speed is still a useful guide to the loads the reciprocating parts of an engine are seeing, but it’s not perfect. The exact loads on these components depend on the accelerations they experience, and the accelerations are dependent on connecting rod length as well as piston speed. Engines with short rod to stroke ratios put greater loads on their pistons than engines with long rod to stroke ratios. In addition, bore-tostroke ratios enter into the picture: highly undersquare engines can usually tolerate higher piston speeds than highly oversquare engines.

The 4000 fpm “limit” of safe piston speed isn’t very useful these days. Materials and designs have improved steadily from the days when 4000 fpm was the limit, and current racing engines make full use of these improvements. Four stroke engines used in road racing applications (both car and bike) routinely reach piston speeds of 4600-4800 fpm. In the short lived world of drag racing engines, speeds well over 5000 fpm are not unheard of.

Finally, while piston speed may give the red line for the pistons and rods, the overall engine red line may be determined by other considerations. The valve gear may not be capable of the same speeds as the other reciprocating hardware. Or, in the interests of better fuel economy through less mechanical friction, rod and main bearing size may have been reduced to the point where these bearings won’t carry the heavy loads that exist at high engine speeds. Or gas flow through the engine may not keep up with extremely high piston speeds, with the result that the piston speed limit is set by non-mechanical concerns. Or, as most likely in the case of the CBX, the engine designers obtained all the power they desired without taking the engine anywhere near the mechanical edge.

As for the piston speeds of the Honda NR500 and NS500 race bikes, we could make some guesses. We don’t know the exact stroke length of either engine, but the NR stroke is probably in the 33 to 38mm range, and the NS stroke is proably somewhere between 54 and 60mm. Assuming the NR turns to 20,000 rpm and the NS to 11,000 rpm, piston speeds would be 4300-5000 fpm for the NR, and 3900-4300 fpm for the NS. These speeds are consistent with what other two and four stroke race engines do.

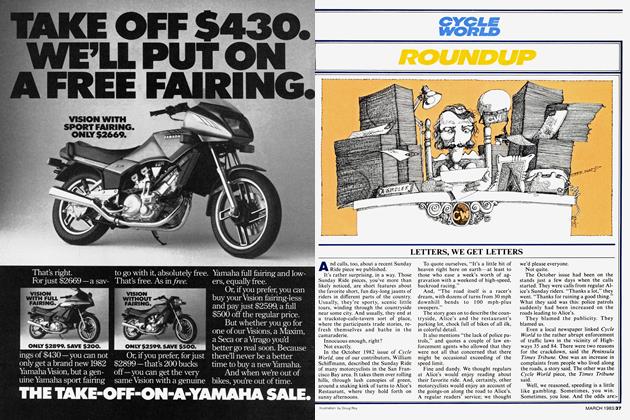

VISION PROBLEMS

Earlier this year I bought a Yamaha Vision, and I am sorry to report that I’m not completely satisfied with it. There is a very noticable lag under acceleration between 4000 and 5000 rpm. In your recent test report of the Double Nickle Rockets you seem to have had the same problem with your test Vision. Is this a problem with all Visions? Can it be corrected? My dealer won’t help me out, so any information you can give me would be appreciated very much.

Jim Larson Sturgeon Bay, Wise.

The hesitation between 4000 and 5000 rpm isn’t uncommon with Yamaha Visions. It’s caused by a momentary leanness of the air-fuel ratio, and can’t be corrected by any simple jet changes. Fortunately, Yamaha is aware of the problem and has a solution. It consists of a kit that changes the 1982 airbox to the 1983 type, with a vacuum controlled flapper valve built into the airbox. The kit includes a replacement airbox top, the upper third of the front carburetor, a new air filter, and all necessary jets. Yamaha dealers should have received kits and the service bulletin describing the changes by the time you read this, and will perform this modification without charge to any 1982 Vision.

A TRICKLE CHARGE

Is there a way to trickle charge a battery without taking it off the bike, via the coil for example?

Ralph E. Rigdon Concrete, Wash.

There’s at least two ways to pump power into one of those buried batteries so many bikes have. The simplest way is to find a wire coming directly off the positive terminal of the battery; the most common one of these is the starter solenoid wire. You can attach the positive lead of the trickle charger to this wire (at the solenoid terminal for instance), and attach the negative charger lead to any good ground on the bike (cylinder fins are good).

An alternative is to wire a quick disconnect electrical coupler directly to the battery, being careful to include a fuse in your lines. This coupler can then be used to charge the battery, or as a accessory terminal to power an electric riding suit, radar detector, or any other device that runs on the right voltage.

NON-SECRET CARB FIX

Okay, I give up! In your 550 sports bike comparison in the August issue, you refer repeatedly to curing the Suzuki GS550M’s ills by a simple, 20 min. carb needle washer switch. Come on! How about a little more detail? I’m going to buy this little beastie, but not until I know how to make this modification, because I will not leave the dealership with it undone. On buy day, I will be bringing a set of long nosed circlip pliers and Phillips screwdrivers along with my checkbook. At least if I screw up in the dealer’s parking lot, I won’t have so far to walk to get help.

Frank L. Moorehead Mammoth, Ariz.

Before the details of the modification, some background information: Emission requirements for motorcycles became law in 1978. According to the law, hydrocarbon and carbon monoxide emissions have to be below specified levels while a motorcycle is ridden over a standard driving cycle, with all speeds and accelerations as specified. This is the same cycle that is used for cars, so the accelerations are relatively low, and any bike larger than a 125 coasts through using mainly the low speed circuits of its carburetors. The conventional approach to reduce hydrocarbon and carbon monoxide emissions is to run a leaner air-fuel mixture, so almost all motorcycles built since 1978 have lowspeed carburetor settings to give lean mixtures. Because the high speed cifcuits (i.e., the main jets) aren’t used during the test, they provide essentially the same mixture as in pre-emission controf days.

On a few motorcycles, the lean settings at lower throttle openings have created drivability problems, such a$ stumbles when the throttle is opened, or have extended the warm-up period where the choke is required to 10 or 15* miles. For these motorcycles, improvements may be made by richening the low ^ speed carburetion. However, if these symptoms aren't present, nothing will by gained by making carburetor changes. If it ain’t broke, don’t fix it.

There are two ways to riehen the low speed mixture, with slightly different effects. A larger pilot jet can be installed (if available), which will have the greatest effect on the mixture when the carburetor slide is less than quarter open. Alternatively, the needle can be raised, which will riehen the mixture most when the slide is between one and three quarters open. From our experience, a needle modification will more likely work on 550 and smaller bikes. For 750s and up, a pilot mixture change may be more appropriate.

That’s as far as we can go with specific advice, except in the case of the 1981 Suzuki GS450, and the 1982 Suzuki GS550M. In both cases, our test bikes suffered from drivability problems and required an extended warm up period. And in both cases, these problems went away when the carb needles were raised by reversing the washers on either side of the carb needle clip. The procedure is as follows:

1) Remove the gas tank, and then, by removing four Phillips screws per carburetor, remove one of the carburetor diaphragm covers. Being careful not to damage the rubber diaphragm, lift out the slide and needle assembly.

2) The next step is the most difficult; the small internal snap ring holding down the pointed nylon piece that acts as a needle retainer must be removed. Most snap ring pliers lack the narrowness and length to reach it, but, with some difficulty, the snap ring can be removed with two sharply pointed awls. With the snap ring removed, lift out the nylon retainer, the carb needle with its two washers, and the small spring beneath them.

3) There will be a small washer on either side of the needle clip. The upper washer is thick and nylon and the lower one is thin steel. Remove the washers from the needle and reverse them. The fat nylon washer is now beneath the spring clip, the steel washer over it, effectively lifting the needle relative to the carb slide.

4) Slide the small spring over the needle and butt it up against the nylon washer. Slide the needle assembly back into the slide, followed by the nylon retainer. Reinstall the snap ring.

5) Replace the slide and diaphragm assembly back into the carb body. Install the diaphragm spring and cover, and repeat the above procedure on the other carburetors.

This modification will almost certainly take you longer than 20 min. to perform if you don’t have snap ring pliers that are long and narrow enough to fit down the opening in the slide. It should improve drivability, but with some reduction in gas mileage. And, because no two motorcycles are exactly the same, this modification shouldn’t be performed until you’ve ridden the bike and are sure it needs it.

THE RIGHT GAS

I bought a 1982 Honda Nighthawk' 650. The salesman said to use unleaded gas. By doing this I would think the valves would not get lubricated. Should I use a leaded or unleaded gas?

Bob Hooper Orange,Calif.

The valve and valve seat materials currently used in most motorcycle engines don’t require any lead in the fuel as a lubricant. As far as the 1982 Nighthawk is concerned, Honda recommends using any pump gasoline as long as the posted octane number is above 86. Unleaded gasoline might provide slightly longer spark plug life because fewer deposits would be left on the sparkplug insulator, but that would have to be balanced against the higher cost of unleaded. So feel free to use any gasoline you desire.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontFor Adults Only

March 1983 By Allan Girdler -

Letters

LettersLetters

March 1983 -

Book Review

Book ReviewVincent Vee Twins

March 1983 By AG -

Departments

DepartmentsRoundup

March 1983 By James F. Quinn -

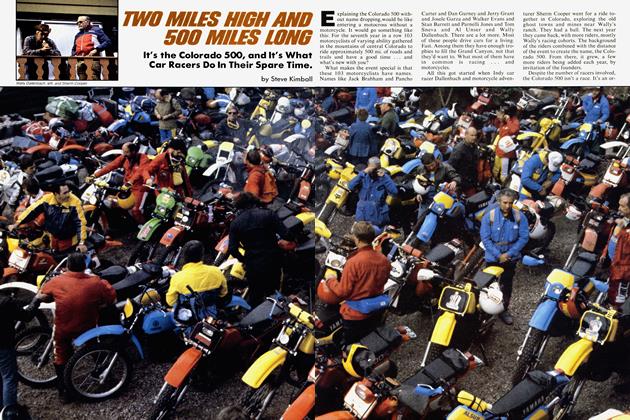

Features

FeaturesTwo Miles High And 500 Miles Long

March 1983 By Steve Kimball -

Technical

TechnicalSouping the 650 Seca

March 1983 By John Ulrich