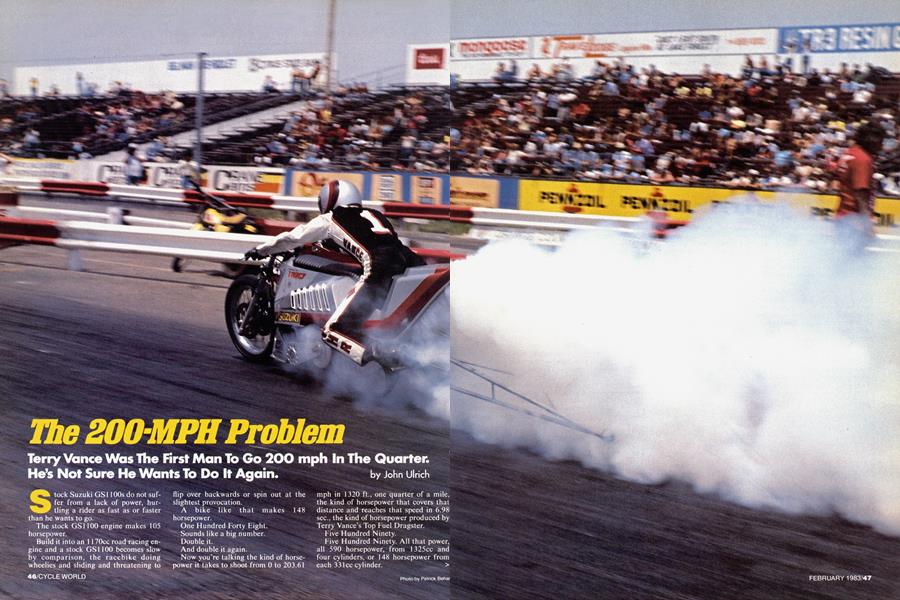

The 200-MPH Problem

Terry Vance Was The First Man To Go 200 mph In The Quarter. He's Not Sure He Wants To Do It Again.

John Ulrich

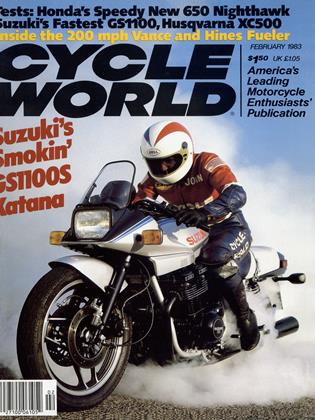

Stock Suzuki GS1100s do not suffer from a lack of power, hurtling a rider as fast as or faster than he wants to go.

The stock GS1100 engine makes 105 horsepower.

Build it into an 1170cc road racing engine and a stock GS1100 becomes slow by comparison, the racebike doing wheelies and sliding and threatening to

flip over backwards or spin out at the slightest provocation.

A bike like that makes 148 horsepower.

One Hundred Forty Eight.

Sounds like a big number.

Double it.

And double it again.

Now you’re talking the kind of horsepower it takes to shoot from 0 to 203.61

mph in 1320 ft., one quarter of a mile, the kind of horsepower that covers that distance and reaches that speed in 6.98 sec., the kind of horsepower produced by Terry Vance’s Top Fuel Dragster.

Five Hundred Ninety.

Five Hundred Ninety. All that power, all 590 horsepower, from 1325cc and four cylinders, or 148 horsepower from each 33 lcc cylinder. >

Top Fuel bikes are impossible to ride. They burn nitromethane, with a pinch of alcohol added to reduce the volatile fuel’s instability, and are supercharged. The power requires a fat, square-edged rear tire so wide the bikes remain upright without stands, and the shape of the tire means the slightest lean moves the contact patch off center, sending the bike sideways and out of control. Fuelers can’t be steered, only vaguely herded in one direction or another with body language, hanging-off and hope.

Fuelers can be ridden at full throttle only—the slightest hesitation on the throttle leans out the mixture reaching the pistons, which promptly melt. Any malfunction that causes detonation or pre-ignition cracks cylinder heads— flaming, superheated combustion instantly turns the cracks into deep, wide, oil-spewing trenches—or breaks crankshafts or knocks chunks out of crankcases.

Most awesome of a Fueler’s powers is the ability to distort perception, turning solid objects fluid, making the track and sky and trees and stands disappear into a cone of blur surrounding the accelerating racebike, only the distant end of the strip remaining distinct.

Riding a Fueler is serious business. It’s been two years since I rode a Top Fuel bike, and the memory is as sharp and cold as it was the moment I rolled to a stop after my first pass and watched my right leg hop and dance and shake with a mind of its own, my shoulders shivering in disbelief. Nobody who races Top Fuel jokes about it. Stand near the starting line and you’ll see eyes grow big and wide and faces set into hard expressions that make it easy to believe what 1981 Top Fuel Champion Sam Wills says about racing in the class: “Going that fast definitely gets your attention.”

Terry Vance is 28 years old. Byron Hines is 33. They’ve been a tearn—rider and engine builder—for 10 years, and partners in their own business, Vance & Hines Racing, for three. They’ve set records, won 12 championships, and dominated racing in every drag classification they’ve entered, starting in the now-defunct Top Gas, moving into Pro Stock, expanding into Top Fuel.

It was Vance’s idea to build a Fueler. He wanted to be the first motorcyclist to reach 200 mph in the quarter, to be the first man to breach a barrier that had become The Goal in Top Fuel, a goal several riders came close to, but never quite reached. For a decade, 200 mph was the impossible dream of motorcycle drag racing. Everybody wanted it, everybody knew that the first person to reach it would go down in history.

Vance wanted to do it with a singleengined, supercharged bike. At the time, Vance and Hines worked for Russ Collins, and Hines had built a V-Eight injected Top Fuel engine based on Honda CB750 parts for Collins’ Sorcerer, which ran 199.55 mph once and never got close to 200 mph again. Hines was skeptical of Vance’s idea.

“I didn’t think that a single-engine bike could go 200,” Hines recalls. “I didn’t see how you could get that much power out of one. From the beginning Terry said one of these bikes would go 200 and that it might as well be ours. He convinced me. I wanted to do it, but I didn’t have any idea what we were getting into.”

It took Hines three months to build the Fueler, working late every day, with another two years of on-and-off development before problems with handling, power output and reliability were resolved. During those two years the only record-setting Vance and Hines did was in the Pro Stock class, and the Fueler blew up and lost races one after another.

Things finally came together for the Fueler for the 1982 NMRA season. It started with Vance knocking a full tenth of a second—a big jump in drag racing— off Sam Wills’ 1981 record. Vance turned 7.17 sec. and 197.36 mph in qualifying at Atlanta, and won. He won again in Gainesville, Florida, and again at East Haddam, Connecticut, turning 7.29 and 199.11. Vance turned 7.31 and 198.27 at OCIR in California, but lost the final when the blower drive belt broke. The blower belt didn’t break at Fremont, California and Vance won again.

Then came the moment when Vance topped 200 mph and undercut 7 sec. at OCIR during one of the regular, nonsanctioned Wednesday night drags. It wasn’t an official record, but everybodyespecially Terry Vance and By-ron Hines—knew that they were the first to reach the magic number, even if the crankshaft broke just before the timing lights.

Hines figured their best chance to put 200 mph into the record books—the best chance to make their feat official—■> would come at the next race, in Indianapolis. But despite an ample supply of new engine parts, they were plagued with old problems: broken blowers, valves bent by rotor pieces; fuel system malfunctions, pistons melted by excessive leanness; broken pistons, valves bent and valve guides broken by piston pieces lodging between valve heads and seats; spark plugs breaking from cylinder pressure, the bike running on three cylinders and still turning 7.20 and 186 mph. At Indy Vance got one good pass in practice, turning 7.05 and 197.80 mph. In the first round of eliminations the primary drive belt lost its teeth and Vance was, out.

Although he didn’t win, Vance maintained his championship points lead none of the other top teams finished. And at the next race, Ateo, fuel system problems and more burned pistons didn’t keep Vance from earning enough points in qualifying and elimination rounds to' clinch the Top Fuel Championship.

Riding a Fueler has gotten Terry Vance’s attention, and now that he’s raced his way to the top of the class, he’s not sure being a Top Fuel pilot is a good idea.

“When we first started building thaf bike it just didn’t go near as fast as it does now,” says Vance. “It was just something I always wanted to do to prove to myself and everybody else that I could do it.”

“We didn’t anticipate the way the sensation of speed would change,” adds* Hines. “Terry didn’t have any idea that the sensation of speed would be so much greater with every three or four mph. It’s a big step. We ran it with a GS1000 motor for a long time and the fastest it went was 185.95 mph, and when it went that fast he said it was a big step from 175 to 185. Then we ran the GS1100 motor basically stock and it went 187.11 mph. We put a 1260cc motor in it and it went 194.80 and he said he could really tell the difference between 185 and 195. That’s when he started talking about how the thing was getting real fast.”

“It turned into the meanest, most firebreathing thing in the world and now I’m stuck with it,” says Vance. “I feel I’m obligated to ride it because Byron put all that work into it. Racing a Fueler is like being marooned on an island made of food. You’ve got to eat, but if you keep on eating you’re not going to have a place to stand. I feel like I have to ride the Fueler to prove myself and to promote our company but sooner or later I’m going to get hurt. So like a guy stranded on an island of food, you have to either lose your appetite or suffer the consequences.”

“We don’t talk about it,” says Hines. “It’s not something we constantly worry about, but it’s there. We both know it’s a pretty dangerous thing. When you keep going that fast the odds keep stacking up against you with every run. Something might break, you might have a flat tire. You just don’t want to keep going that fast if you don’t have to.”

“It’s not something we have plans to do in the future because it’s just going too fast,” says Vance.

The mental pressure of riding a Fueler is matched by a different kind of pressure, mechanical pressure, applied to the motorcycle’s components. Fuelers make far too much power for street bike transmissions and clutches, so it’s standard Fueler practice to cut stock crankcases off behind the crankshaft, removing the section that normally carries the transmission and clutch. A plate seals off the cases, and power is routed through a special primary drive to a race car clutch and two-speed transmission. If the engine detonates during a run, it’s common for Fuelers to crack crankcases, especially in the areas directly supporting the crankshaft, and to turn perfectly good stock connecting rods into S-shaped deformations.

It was after one of the early GS1000based engines in the Vance and Hines Fueler blew a 3.0-lb. chunk of aluminum out of its cases—and bent the connecting rods—that Hines decided upon direct action.

He shipped the damaged cases, the retrieved piece of blown-away aluminum, and a handful of bent rods to the Suzuki factory in Japan.

Maybe it would be good if we included a drawing of what we wanted for a connecting rod, Hines thought aloud, and Joe Pace, hired by Vance and Hines to drive their truck to races, volunteered that he had taken a drafting class in high school. Make the rod as wide as you can, Hines told Pace, and make a rib around the big end. Pace did, and his pencil-onpaper drawing went in the box with the damaged parts.

Two months later Hines received a phone call from an official at U.S. Suzuki. The factory wanted to .know if Hines planned to use a GS1000 or a GS1100 engine in the Fueler. Hines had already started using the GS1100 engine, and said so.

Four months after that, several boxes arrived. They contained four sets of crankcases identical to stock GS1100 cases except for an important difference: they were sand cast iron. Other boxes contained 10 sets of chrome-moly steel connecting rods, adapted for GS1100 use, but otherwise as designed by Joe Pace, truck driver.

The Vance and Hines Fueler hasn’t cracked a set of cases nor bent a rod since.

The iron cases, with the back section cut off and ready to install, weigh 40 lb. more than the aluminum cases they replaced. The special connecting rods weigh 150 grams more than the stock rods.

Direct factory involvement stops with the cases and rods. The rest of the bike is a mix of kit parts and hand-built pieces. The crankshaft ends, for example, are extended to carry a primary belt drive pulley on the left and pulleys for the supercharger, magneto, oil and fuel pump drive belts on the right. Hines sent the crank ends out to be extended by Loring Sollender of Bender Machine in Vernon, Calif. Sollender drills a hole in each crank end, then mills a piece of chrome moly bar stock down at one end. The milled end of the bar fits into the hole drilled in the end of the crankshaft, and both the bar and the crank are relieved to form a V-shaped notch at the point where they join. Sollender fills the notch with weld and grinds down the joint.

The extended crank ends, the special connecting rods and the rest of the crank pieces are assembled by Kevin Murphy, who works for Hines and does all the crank work for VHR racebikes and customers. Murphy welds 360° around each press-fit crank pin to prevent twisting.

The primary drive is a 3.34-in.-wide, toothed belt made by Uniroyal, which Hines selected after consulting with Uniroyal R&D engineer Howard Forester, and supplied through Primo Belt Drives. It carries the power to a Crowerglide 10-in. sprint car clutch, which drives a planetary two-speed B&J top fuel car transmission. The transmission needs only two speeds because a blown fuel motor’s torque curve is nearly flat, and, Hines says, using more than two speeds would increase problems with wheelspin. Vance shifts by pushing a big red button on the left handlebar.

The rear wheel is driven through a dual-row 520 roller chain and a set of dual-row sprockets made by Azusa Engineering. Chain tension is adjusted with an idler sprocket, and the rear axle is fixed. The rear tire, a Goodyear racing slick, is 12.5-in. wide and stands 30 in. tall. The rear wheel is spun aluminum and is made by Kosman Specialties.

The big displacement comes from a huge, 80mm bore (stroke remains stock at 66mm) made possible by using a Vance & Hines big block cylinder casting, which has extra material around each cylinder sleeve to increase support and avoid distortion problems, which can cause excessive blow-by, which removes oil from the cylinder wall, which causes the piston to first seize and then melt.

Pistons are made by Wiseco, are forged, and yield a static compression ratio of 6:1.

The cylinder head is ported by Bob Wilkenson, who was trained by Hines and who does all the company’s porting. The head for the Fueler isn’t ported as radically as heads destined for pro stock or road racing use, because extra material must be left around the valve seats.

The problem, Hines explains, is that the cylinder pressure is so high it flexes the combustion chamber and causes the valve seats to move around. A new cylinder head needs a valve job after two or three runs, Hines says, but then will last for about 10 runs if nothing goes wrong.

After porting, the cylinder head is assembled by Mike Robertson, who also does all the Vance & Hines valve jobs. Intake valves are the same size as stock, 27mm, but exhaust valves are 1mm oversize, 24mm, and both intake and exhaust valves are stainless steel. Camshafts are the same as used in the Vance & Hines Pro Stocker and have 0.345 in. lift. The cam chain is made by Tsubaki.

The key to Top Fuel power is the supercharger, or blower, and Hines uses a blower from Jerry Magnusson Superchargers. The blower has two three-vane rotors positioned so the individual vanes overlap and mesh as the rotors turn. The blower displaces 80 c.i. with every revolution and is geared to turn 30 percent faster than the engine, which revs to 12,000 rpm.

The mixture of nitromethane and alcohol is injected through one set of nozzles located upstream of the blower and through another set located downstream of the blower, one nozzle in each cylinder’s intake tract.

There are several advantages to injecting fuel upstream of the blower. The fuel fills the clearance space between the rotor vanes and the blower housing and between the tip of each rotor vane and the hub of the other rotor, increasing boost pressure. The turning rotors swirl ard mix the fuel and incoming air, and the fuel cools the rotor and allows the use of closer tolerances, which again increases available boost.

The injector located upstream of the blower contains a butterfly valve, which is connected to the throttle. The injector body is rectangular, measuring 4.0 x 3.0 in. and Hines says switching to this injector from the 3.0-in. round injector body and butterfly used previously increased boost pressure from 23 to 25 p.s.i.

The aluminum manifold which carries the blower and directs blower output into the individual cylinder ports was carved out of a block of aluminum by Hines in a non-stop, 10-hour stint on a milling machine.

The injector nozzles in the intake tracts can be adjusted individually, allowing Hines to compensate for any imbalance in the fuel distribution or other engine running characteristics. The center two cylinders run hotter than the two outside cylinders, for example, so Hines increases the amount of fuel reaching those cylinders to avoid problems stemming from too lean a mixture.

Overall fuel distribution is controlled by three jets, which are called pills because they look like an aluminum aspirin tablet with a hole drilled in the center. Which pill is used at any given throttle opening or rpm is controlled by fuel pressure, which increases with rpm, and a barrel valve, which meters fuel in the correct proportion for the amount of throttle butterfly opening.

The idle bypass pill bleeds excess fuel pressure from the fuel pump to the fuel tank at idle. The main bypass pill bleeds excess pressure back to the tank at all throttle openings, and the overall fuel mixture can be made richer by installing a smaller pill (because less fuel is returned to the tank) or leaner by installing a larger pill (because more fuel is returned to the tank).

The high-speed bypass pill’s barrel valve opens at a preset, adjustable fuel pressure corresponding to the rpm at which the engine is operating at maximum efficiency, or, when air flow through the intake system cannot be increased. If the high-speed bypass pill did not bleed off pressure at this point, fuel pressure (hence fuel delivery through the nozzles) would continue to increase while air flow (hence air delivery to the cylinders) did not, resulting in a rich mixture.

The trick is to give the engine just the right amount of fuel at every rpm, without going too lean or too rich. It’s at that point, Hines says, that the bike makes a lot of horsepower.

The exhaust system is far less critical. Blown motors don’t need exhaust scavenging, so the pipes are simple and short and relatively straight and thick-walled, all being considerations that reduce the likelihood that the pipes, which glow red during passes, will melt.

The chassis came in kit form from Kosman Specialties. The frame is chrome-moly steel and has an 86-in. wheelbase and 38° of rake. There is no rear suspension and the chassis came with Ceriani forks. When Hines installed the heavier iron engine cases in the bike, it developed handling problems, veering left suddenly when the front tire touched down at the end of a pass. Hines replaced the Ceriani forks with larger, heavier forks off a GSI 100E and installed a tubular fork brace he saw in a magazine ad, and the handling problems disappeared. Hines also runs two steering dampers.

Hines made the engine mount plates, which carry the engine, clutch and transmission and form a solid bridge between the front and rear ends of the bike.

The Fueler’s fiberglass body is designed to grab attention and isn’t based on aerodynamics. The original body weighed 60 lb., too heavy to suit Hines, so a second body was built of Kevlar. It weighed 11 lb. but cracked too easily, so Hines and assistant Ron Durham reinforced it with fiberglass, ending up with a strong body that weighed 22 lb.

The triangular fuel tank is mounted ahead of the engine, hidden by an aluminum cover which must be replaced frequently—wind pressure regularly causes it to bend and crack.

Building and assembling the parts was just the beginning. The challenge now, Hines says, is to improve reliability. “If we can get it to consistently run 200 to 202 mph without hurting the motor, then I think we’ll have succeeded. It’ll go in the sixes if it turns 200, say 6.90 sec. My next goal is to make two consecutive 6sec. passes at over 200 mph.”

I didn’t think Vance would let me ride his Fueler. I wasn’t even sure I wanted to ride it. I asked anyway.

“It still makes me nervous,” replied Vance in disbelief. “I’m a lot more comfortable with it now because we have it handling better and I’m more familar with it, but it’s not that simple.

“You have to be confident enough to hold the throttle wide open from the start, that’s the problem. Once you get to that point, then riding the bike is a lot easier. When you try to roll it off the line it starts wandering around and getting all weird and then when it comes on the power it goes off in the direction it’s wandering in, instead of straight. If you just hammer the throttle it hops right on the wheelie bar and goes. If somebody who hasn’t ridden it before gets on it, they won’t have the confidence to just do that. I mean, I wouldn’t do that. No way.

“Riding it is just blinding speed. It’s accelerating so fast through low gear now that it’s really hard to shift into high gear at the right time. You have to be in a pattern of doing it to do it right. You couldn’t just jump on it and go fast. I just don’t see any way.

“People see it from the grandstands and it goes by, and it goes by fast, sure, but they don’t get any of the actual suspense of the speed because they’re not on it or right next to it. If you stood on the finish line as it came by, you’d understand.”

Vance is excited and the words come rapidly. “I don’t think the drag bike guys get enough credit as far as rider ability goes. To go fast you have to ride the bike really well and then cut a good light on top of that. It’s pretty hard when it’s moving around and accelerating that hard. It’s traveling more than 300 feet per second when it gets to the finish line and that’s moving right along.”

“Plus the reflexes,” says Hines. “When you realize something’s wrong, it’s too late.”

“That’s right,” says Vance. “You could be just another OCIR sign.”

“Or a notch in the guardrail,” says Hines.

They aren’t smiling.

Nobody who knows jokes about Fuelers.

I’m not riding. H

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontSaturday Madness

February 1983 By Allan Girdler -

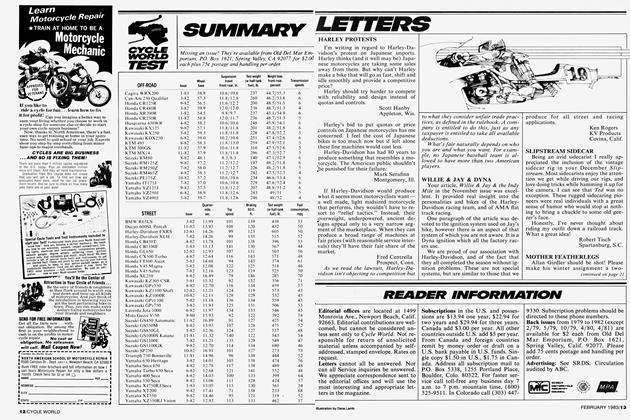

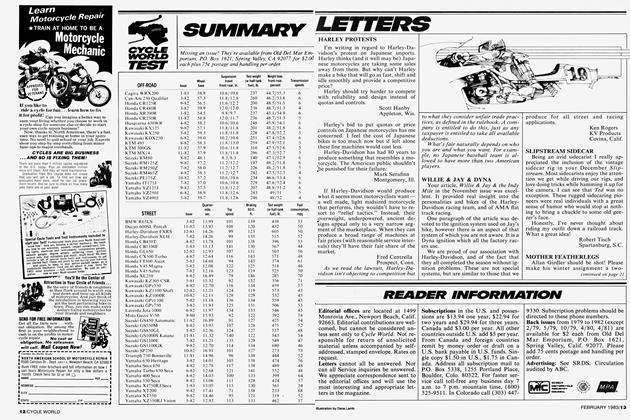

Cycle World Test

Cycle World TestSummary

February 1983 -

Letters

LettersLetters

February 1983 -

Departments

DepartmentsRoundup

February 1983 -

Features

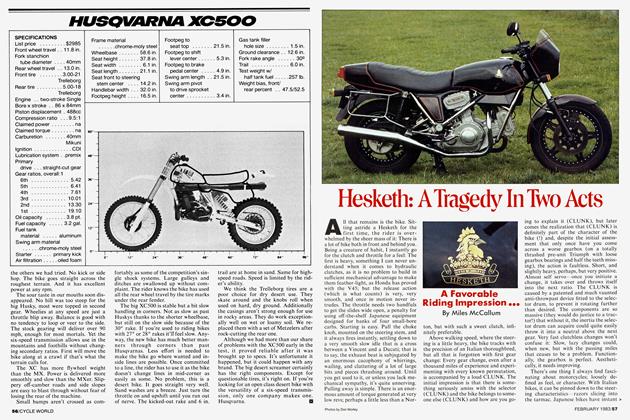

FeaturesHesketh: A Tragedy In Two Acts

February 1983 By Miles McCallum -

Evaluation

EvaluationSmith Roll-Offs Makes Normal Tear-Offs Obsolete

February 1983