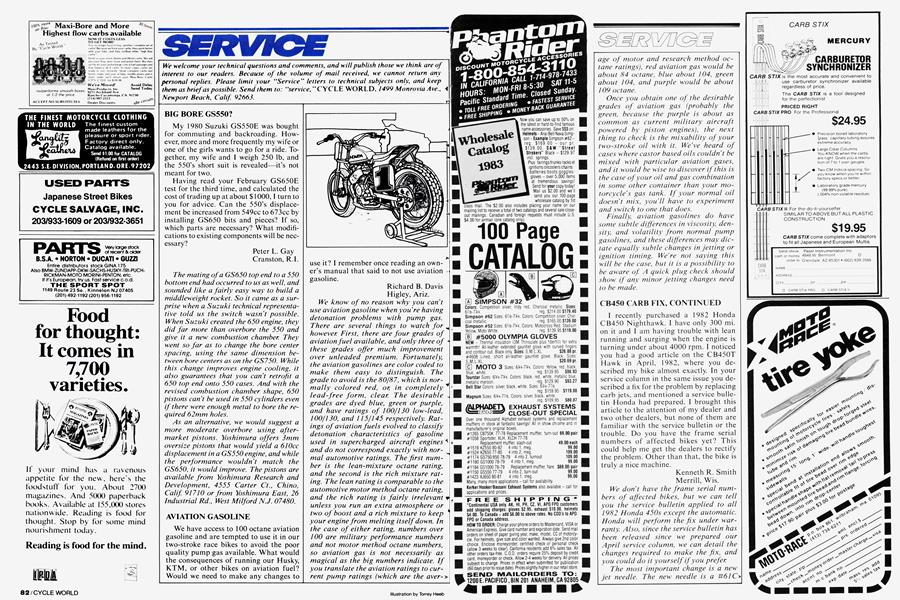

SERVICE

We welcome your technical questions and comments, and will publish those we think are of interest to our readers. Because of the volume of mail received, we cannot return any personal replies. Please limit your “Service ” letters to technical subjects only, and keep them as brief as possible. Send them to: service, ’’CYCLE WORLD, 1499 Monrovia Ave., 4 Newport Beach, Calif. 92663.

BIG BORE GS550?

My 1980 Suzuki GS550E was bought for commuting and backroading. However, more and more frequently my wife or one of the girls wants to go for a ride. Together, my wife and I weigh 250 lb, and the 550’s short suit is revealed—it’s not meant for two.

Having read your February GS650E test for the third time, and calculated the cost of trading up at about $ 1000,1 turn to you for advice. Can the 550’s displacement be increased from 549cc to 673cc by installing GS650 bits and pieces? If so, which parts are necessary? What modifications to existing components will be necessary?

Peter L. Gay

Cranston, R.I.

The mating of a GS650 top end to a 550 bottom end had occurred to us as well, and sounded like a fairly easy way to build a middleweight rocket. So it came as a surprise when a Suzuki technical representative told us the switch wasn’t possible. When Suzuki created the 650 engine, they did far more than overbore the 550 and give it a new combustion chamber. They went so far as to change the bore center spacing, using the same dimension between bore centers as on the GS750. While this change improves engine cooling, it also guarantees that you can’t retrofit a 650 top end onto 550 cases. And with the revised combustion chamber shape, 650 pistons can’t be used in 550 cylinders even if there were enough metal to bore the required 62mm holes.

As an alternative, we would suggest a more moderate overbore using aftermarket pistons. Yoshimura offers 3mm oversize pistons that would yield a 6 Wee displacement in a GS550 engine, and while the performance wouldn’t match the GS650, it would improve. The pistons are available from Yoshimura Research and Development, 4555 Carter Ct., Chino, Calif. 91710 or from Yoshimura East, 26 Industrial Rd., West Milford N.J. 07480.

AVIATION GASOLINE

We have access to 100 octane aviation gasoline and are tempted to use it in our two-stroke race bikes to avoid the poor quality pump gas available. What would the consequences of running our Husky, KTM, or other bikes on aviation fuel? Would we need to make any changes to

use it? I remember once reading an owner’s manual that said to not use aviation gasoline.

Richard B. Davis

Higley, Ariz.

We know of no reason why you can’t use aviation gasoline when you’re having detonation problems with pump gas. There are several things to watch for M however. First, there are four grades of aviation fuel available, and only three of -these grades offer much improvement over unleaded premium. Fortunately, the aviation gasolines are color coded to make them easy to distinguish. The grade to avoid is the 80/87, which is normally colored red, or, in completely ' lead-free form, clear. The desirable . grades are dyed blue, green or purple, and have ratings of 100/130 low-lead, 100/130, and 115/145 respectively. Ratings of aviation fuels evolved to classify detonation characteristics of gasoline used in supercharged aircraft engines * and do not correspond exactly with normal automotive ratings. The first number is the lean-mixture octane rating, and the second is the rich mixture rating. The lean rating is comparable to the automotive motor method octane rating, and the rich rating is fairly irrelevant * unless you run an extra atmosphere or two of boost and a rich mixture to keep your engine from melting itself down. In the case of either rating, numbers over 100 are military performance numbers and not motor method octane numbers, so aviation gas is not necessarily as magical as the big numbers indicate. If you translate the aviation ratings to current pump ratings (which are the aver-> age of motor and research method octane ratings), red aviation gas would be about 84 octane, blue about 104, green about 104, and purple would be about 109 octane.

Once you obtain one of the desirable grades of aviation gas (probably the green, because the purple is about as common as current military aircraft powered by piston engines), the next thing to check is the mixability of your two-stroke oil with it. We’ve heard of cases where castor based oils couldn’t be mixed with particular aviation gases, and it would be wise to discover if this is the case of your oil and gas combination in some other container than your motorcycle’s gas tank. If your normal oil doesn’t mix, you’ll have to experiment and switch to one that does.

Finally, aviation gasolines do have some subtle differences in viscosity, density, and volatility from normal pump gasolines, and these differences may dictate equally subtle changes in jetting or ignition timing. We’re not saying this will be the case, but it is a possibility to be aware of. A quick plug check should show if any minor jetting changes need to be made.

CB450 CARB FIX, CONTINUED

I recently purchased a 1982 Honda CB450 Nighthawk. I have only 300 mi. on it and I am having trouble with lean running and surging when the engine is turning under about 4000 rpm. I noticed you had a good article on the CB450T Hawk in April, 1982, where you described my bike almost exactly. In your service column in the same issue you described a fix for the problem by replacing carb jets, and mentioned a service bulletin Honda had prepared. I brought this article to the attention of my dealer and two other dealers, but none of them are familiar with the service bulletin or the trouble. Do you have the frame serial numbers of affected bikes yet? This could help me get the dealers to rectify the problem. Other than that, the bike is truly a nice machine.

Kenneth R. Smith

Merrill, Wis.

We don’t have the frame serial numbers of affected bikes, but we can tell you the service bulletin applied to all 1982 Honda 450s except the automatic. Honda will perform the fix under warranty. Also, since the service bulletin has been released since we prepared our April service column, we can detail the changes required to make the fix, and you could do it yourself if you prefer.

The most important change is a new jet needle. The new needle is a #6/C> (Honda Code 125734, part number 16113-MCO-305), and replaces the #61A needle that came in each carburetor. This change richens the part throttle mixture, and, according to Honda, will eliminate the surging problem in 90 percent of the cases. We talked to local shops who had performed this change on customers’ 450s, and they reported good results.

The second part of the fix is for the 10 percent not cured by the needle swap, and involves replacing the EPA-mandated nonadjustable idle-mixture adjustment screws with adjustable adjustment screws. The new screws have Honda code number 081566, and part number 16016-413-751. (The old screws have projections that hit against the float bowl when given more than half a turn. If you remove the projections, you could avoid buying the new screws.) The recommended initial adjustment is two and a half turns out, and Honda has a procedure called the “idle drop method’’ described in the 1982 CB/CM450 shop manual for fine tuning the idle mixture. The idle drop method is fairly involved, and if you want it performed on your bike we would suggest either referring to the shop manual or letting your dealer do it.

Then again, we suspect the purpose of the idle drop method is to generate an idle mixture on the lean edge of the acceptable range. If a person were more concerned with how his machine ran rather than how it would perform on an emissions analyzer, he could resort to the archaic pre-1978 procedure of adjusting the idle mixture until he got the fastest idle and the best low-speed running. The idle mixture adjustment screws on the CB450 carburetors control fuel flow, so turning them inwards leans the idle mixture, and outwards richens it.

BLOWN FUSES

My 1975 Honda 400F had the peculiar problem of blowing the main fuse at least once a year. I finally determined that this was not because of overload, but because of vibration in the metal fuse clamps inside the fuse box. These clamps are somewhat loose. Apparently they rattle the metal end of the fuse, causing the fuse wire to fatigue and break. I solved the problem by putting foam weather stripping inside the fusebox cover. When the cover is closed this presses against the fuses and damps the vibration. 1 haven’t blown a fuse in over 30,000 mi.

Bill Meyerson

North boro, Mass.

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsUp Front

November 1982 By Allan Girdler -

Letters

LettersLetters

November 1982 -

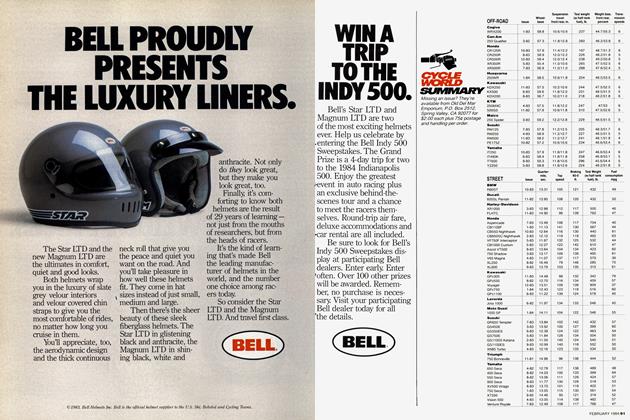

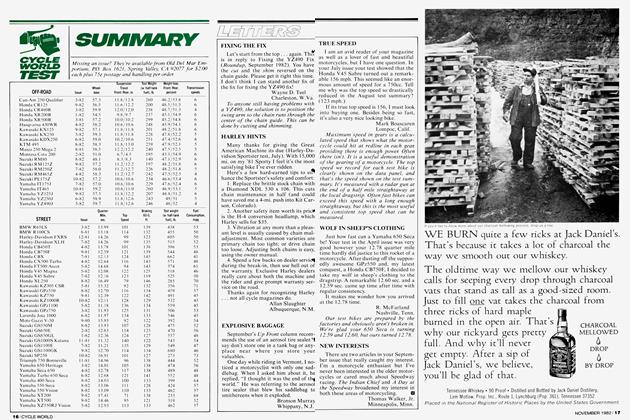

Cycle World Test

Cycle World TestSummary

November 1982 -

Cycle World Roundup

Cycle World RoundupAutomatically Faster

November 1982 -

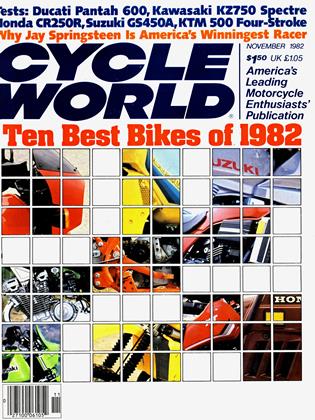

Ten Best Bikes of 1982

Ten Best Bikes of 1982Even When They're All Good, Some Are Better.

November 1982 -

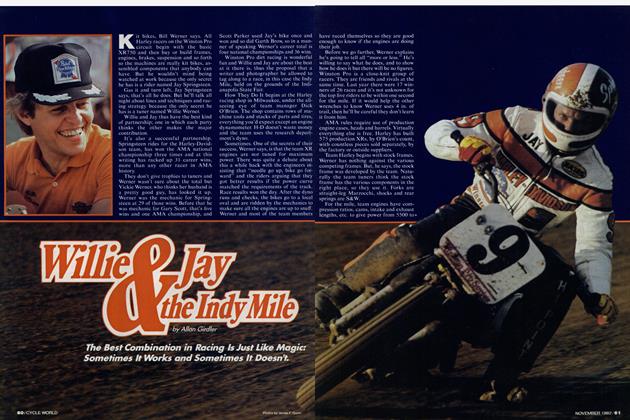

Competition

CompetitionWillie & Jay the Indy Mile

November 1982 By Allan Girdler