Winners That Never Were

While Ignoring the Present, Britain Designed for the Future.

Gordon Schindler

Knowing how to do it, the axiom goes, doesn’t get it done. And so it was with the British motorcycle industry in the mid-Sixties. While Britain’s motorcycle leadership faded, starting with the smallest motorcycles, the large, successful British companies ignored the losses of companies like James and Francis.

After all, business was good for the makers of big bikes like BSA and Norton and Villiers. The colonies were eating up all the bikes that could be produced. On a corporate level nobody looked ahead, though underneath the apparent unconcern, the minds of some of Britain’s best designers had turned to the future. Everywhere, there were ideas, weird and wonderful ideas, for possible motorcycles.

Without a formal declaration of war, designers began suggesting possible motorcycle engines in articles published in the British motorcycle magazines. The idea was to beat the Japanese at their own game: design an engine to beat the world.

“It is common knowledge that our manufacturers have given little encouragement to new talent in the past 20 years” wrote designer G.H. Jones. He then proposed a four-cycle, 250cc, 60° V-12 (Fig. 1) for, as he said, “To copy slavishly the Japanese theme of double ohc, four valve, pent-roof heads, would be doubtful tactics, for they have considerable lead here and may well be nearing the ultimate in this design.” Agreeing with other writers, he added “I favor the 250cc class. The idea of selecting any class because it is the easiest shows a defeatist attitude to start with. We can take it for granted that no class will be easy; our competitors will not obligingly stand still!”

Jones proposed an oil-cooled engine using two small radiators, one on each side of the bike. To get away from the usual single carb per cylinder, he suggested using “a single-piece instrument serving all 12 cylinders through two banks of six chokes, with two linked rotary throttles and three float chambers, each feeding four cylinders.”

Parallel valves were to be operated by a single overhead cam through short tappets. Speeds in excess of 20,000 rpm were anticipated and at such speeds, Jones believed that only one piston ring would be necessary.

Advocating an opposite approach, builder Bert Greeves proposed making “No ultra-specials. It’s better to design something you can afford to make.” He proposed a 125cc two-stroke Twin, which could be enlarged to a 250cc inline Four.

Greeves maintained that the British world beater should not be some racing special but bear as much resemblance to production models as possible. He thought that a small factory like his could produce such a machine. “The basic unit would have to be a two-stroke,” he said, “since it would have to be easy to multiply”it would have normal porting, not disc valves because he believed that piston-controlled porting “gives a better gas flow than that of disc-valve engines.” Water-cooling would be necessary to keep frontal area to a minimum, for, as Dr. Joe Ehrlich had pointed out, each square inch of frontal area saved represented a gain of half a horsepower.

Phil Vincent’s V-Eight two-cycle proposal was perhaps the most complicated technically of any offered. This is seen in Fig. 2. He advocated building a 500cc class engine because “a machine built to uphold British prestige must enter the fray where> foreign competition is strongest. There would be little prestige in taking on the elderly MV Agusta and occasional elderly Gilera, even if we beat them handsomely.”

Phil envisioned a complex engine design utilizing pumping action on the lower end of each piston (Fig. 3) as well as “pistoncontrolled transfer ports” in conjunction with a “timed inlet valve,” as well as four exhaust valves per cylinder.

Like Greeves, he advocated building a small test unit, such as a 125cc Four, not only to speed up development work but as protection in case the 500cc class was ever eliminated. “The four-stroke probably offers the quickest way to get . . . results . . . but I am sure that, three or four years for development work, a two-stroke can be designed that will beat any possible fourstroke” Phil said.

He said the 32-pipe exhaust system could be siamesed, giving only 16 pipes and as for the great number of exhaust valves contemplated, he said of objections “Do we want to win or trail around in third place?”

Someone suggested that Phil use sleeve valves to simplify his complicated fourvalve exhaust system. He admitted that would be better “but unless we can draw freely on the knowledge of the aircraft industry and get their assistance—most improbable—we should be letting ourselves in for far too much research work;” and, as Jones pointed out, four years’ development work was much too long! That was 15 years ago.

Allan Baker offered the design shown in Fig. 4. If the FIM somehow could be induced to sanction exhaust turbocharging, he said, the prospects for a design much simpler than Vincent’s would be excellent. He proposed a four-cylinder, opposed-piston configuration, with pistons controlling the ports in the usual manner, one piston operating the exhaust ports and the other the intake of fresh air. The fuel was to have been injected after the exhaust ports closed, preventing fuel loss. No explanation was given for the different-sized pistons.

Contributor Bernard Hooper suggested making a flat Four 250cc, two-stroke engine, seen in Fig. 5. It was to have had two geared cranks and a double-acting disc-> inlet valve running at one-half crank speed.

Commented G.H. Jones on the use of two geared crankshafts, “This feature would dispose of navigational difficulties arising from gyroscopic precession, but it is not clear whether final drive shaft, with its transverse torque reaction, is contemplated. In any case, as the engine is liquidcooled and the crankshafts are short . . . The whole layout should be attractive and not too costly.”

Commenting on other submissions, Jones continued with “Paul Wright votes for a 250cc three-cylinder two-stroke on the lines of the old 350 DKW. In many ways, this was an attractive scheme since the engine is reasonably narrowand the cylinders are well separated for air cooling. But DKW was not overwhelmingly successful—though this was probably not due to the cylinder layout.

“Some very sensible observations are made bv Geoff' Monty and he prefers a 500cc four-stroke Twin with four-valve, double-ohv cylinders built into a machine no larger or heavier than a normal 125. It would be cheap to make but, remembering the old Porcupine AJS and the more recent Bianchi and Jaw-a Twins, one wonders whether better than second or third placings could be achieved.”

A.D. Baxter didn’t mince words, when he wrote “We won't catch the Japs along orthodox lines. A British Honda would only make us look silly.”

While saying the most practical thing would be the overhead exhaust valve arrangement a là Vincent, to get extremely high rpm. he favored “cylindrical rotary valves (Pig. 6). Since the NSU-Wankel engine manages to separate the burning and fresh charges in the adjacent chambers by a single sealing strip in a groove, the seals for my rotary valve must work.”

Baxter chose to locate them in the housing rather than on the rotor so that oil could be fed to the seals just beyond the ports and scraped from them just before passing over the ports.

While not directly referring to Baxter’s design. T.F. Carter wrote in, commenting on revolutionary designs in general. “The pre-war Aspin (rotary valve) engine was said to give a phenomenal performance on the test bed. In vain—we have awaited its production for a quarter of a century. More recently, Granville Bradshawproduced a torroidal (curved-piston) design . . . Where is it now?”

Fig. 7 shows an ultra-short stroke engine design by J.G. Lovegrove, utilizing the unique Scotch yoke form of crank mechanism. While this is a very old idea, it has yet to be used on a commercially successful engine. This design would have had a minimum of friction and wear due to the elimination of side-thrust. “The big end would be adequately oiled (no small end)” noted Lovegrove. adding that “piston cooling with oil could be easily arranged through a hollow piston rod. Ordinary compression would be limited only by the volume of the transfer ports. The more over-square the bore, the fewer pots would be necessary for a given capacity and piston speed.”

Like Phil Vincent. Lovegrove chose to use the bottom of the pistons for pumping purposes, thru the same “inlet . . . timed valves.” These were undetailed in Vincent's case because of patent applieations. Lovegrove chose to use two exhaust valves per cylinder.

A year after proposing his 12-cylinder 250. G.H. Jones cut his offering drastically by submitting plans for a three-cylinder engine design (Fig. 8). Under the heading A THREE TO BEAT ALL COMERS. Jones reiterated his belief that an entirely newdesign was needed to “beat wellentrenched foreign competition.”

He proposed a lOOcc displacement size because then “we are forced to set our sights high rather than follow the inefficient old big-capacity-high-weight theme.” He proposed three cylinders “because. after long neglect, this type has nowcome to the fore in no uncertain terms by winning the 500cc world championship.”

His small-displacement, oil-cooled engine would also get “rid of the vibration bogy and. its ultra-light reciprocating parts . . . spell reliability . . . (and) a three is inexpensive and easy to make.”

He chose a single overhead cam because Jack Brabham in his Repco-Brabham, powered by a single ohc engine “beat the best of the double-ohc engines.”

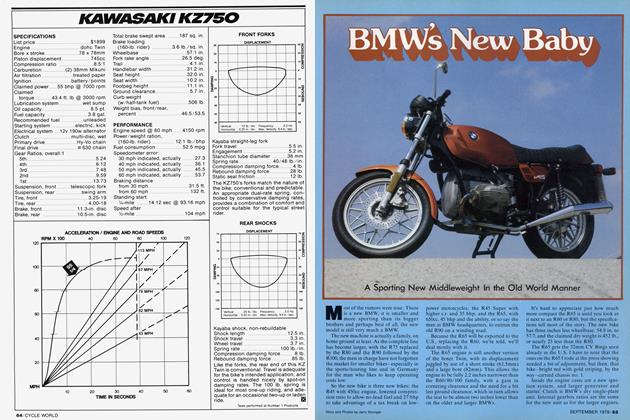

R.N.W. Holmes disagreed, offering his version of a world beater design seen in Fig. 9. This was to be an oil-cooled 350cc, overhead cam Four. With a CR of 11:1, Holmes anticipated 60 bhp at 11,000 rpm. The use of oil cooling “not only obviates distortion at any local hot spots but it also allows cylinders to be set much closer together.” with resulting advantages. Frontal area would be reduced by the elimination of an oil radiator and attendant plumbing.

Operation of the four valves per cylinder was to have been by a train of pinion gears. Fuel was to have been supplied by “a bank of eight carburetors of my own design to ensure increased bhp, plus constant feed when cornering.”

The world beater effort never reached fruition because they weren’t able to obtain sufficient financing, apparently nothing from the industry itself. A lottery (Manx) was depended upon to raise 25.000 pounds, some $75,000. It failed to bring in what was expected. Even if it had, there apparently was no central organization which would have decided upon the ultimate engine design to be built.

Dr. Ehrlich had suggested that w hatever money was available should go to the designer of the first bike to win a Grand Prix race “in really competitive circumstances.” Exactly where the money was to come from to build such a Grand Prix beater in the first place was never explained.

Holmes did say in this respect, however, “Certainly it would cost nothing like 20.000 (pounds) to build the RNW/J (Holmes’ engine, based on Jones’ threecylinder design), particularly with assistance from accessory and equipment manufacturers. All the design work is already done . . . Remember the Guzzi VEight was built in a matter of months by eleven men, only one of whom did the actual assembling!”

While several professional designers, including Phil Vincent and G.H. Jones advocated advanced and even radical solutions, claiming that foreign competition had developed conventional designs to their limits. or were about to do so, time has now shown that this same competition has continued w ith their conventional designs and that even they did not require or think it was necessary to develop V-12s, sleeve valves, rotary valves or “an entirely new conception with superlative merit” as Jones stated in offering his three-cylinder. In fact, there was nothing new in his Three and even though he didn’t know' it, he was closer to developing a world beater than with his much more sophisticated V-12. as time has shown that this conventional approach was all that the foreign competition needed, not only to overtake the British but to stay ahead of them.

What is needed today is a different matter. Perhaps the life of the overhead cam, poppet-valve engine is coming to an end. Perhaps the time is ripe for development of the rotary valve or sleeve valve. The Esso-cruciform engine has recently incorporated the Cross rotary valve as well as the Scotch yoke, with apparent success. Still little has been heard of it recently. Will this be the “entirely new conception with superlative merit?”

Only one thing seems certain at this point. If it is, it won’t come from the British motorcycle industry.

More’s the pity. Si