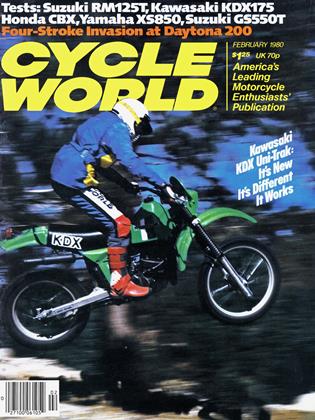

SPRING FEVER

How Springs Can Work for You in Your Motorcycle's Suspension.

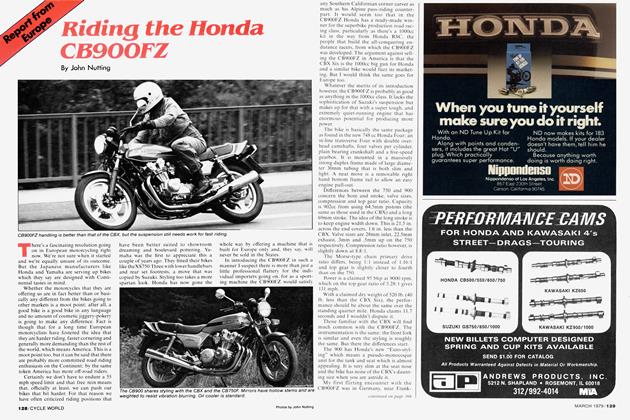

John Nutting

Coil springs have been such an integral part of motorcycle suspensions in the past three decades that it's been far too easy to take them for granted. Simple and reliable, they’ve been silent servants in the war against potholes and bumps and the maintenance of as smooth and as comfortable a path for the enjoyment of our pastime as possible.

And if there are signs that the coil spring is to be pensioned off by new innovations in the air suspension field it is only because of the special requirements being made predominantly in the touring market. Air springs are infinitely adaptable to a wide range of loads by changing the air pressure. But their complexity and cost puts a limit on their widespread use. An indication of their reliability is that most air system makers still use coil springs as a backup.

Coil springs will be with us for a long time to come and it’s not difficult to see why. They’re simple, compact, not affected by heat, fairly easily tuned to individual taste and above all, cheap. If they do have a fault then it’s a lack of understanding of what they’re able to achieve.

First, confusion has arisen over the roles played by the suspension springs and by the shock absorbers. While the purpose of the springs is to support the motorcycle at the same time as absorbing bumps in a road surface, the shocks (more properly dampers) are specifically designed to limit the fluctuations that occur after a force (such as a bump) has been applied to the spring.

The results of inadequate or even nonexistent damping for a spring are only too obvious if you’ve seen an automobile with shot shocks. After traversing a bump it will continue to bounce until another bump impedes its progress or control is lost. Either way, the vehicle follows a path that is neither condusive to the active enjoyment of the vehicle nor its safe progress.

The same conditions can arise on a motorcycle with even more catastrophic results if the bouncing occurs when leaned over in a bend. The up and down bouncing can be accompanied by a side to side weave that precipitates loss of control even earlier than in an auto.

But either way, it’s not the springs that are at fault but the inability of the damper to prevent the suspension’s inevitable desire to keep bouncing after hitting a bump.

Second, it’s widely thought that the adjusters on the rear springs of most motorcycles stiffen the suspension. That advertising often promotes the idea of “adjustable suspension” when there’s a lack of other useful features on a motorcycle to draw attention to hasn’t helped in dispelling the notion.

The truth is that preload adjusters, to give them the correct name, simply vary the amount by which the spring is compressed while the machine is unladen. Since the stiffness of the springs remains the same, there can be no change by altering the preload. However, since the preload adjuster can alter the height of the bottom of the spring it can vary the height of the motorcycle chassis and therefore its road clearance. The chance of bottoming the springs under a heavy load is not lessened, though.

Such misconceptions don’t help in the understanding of how springs work in motorcycle suspensions. But to help in grasping the importance of spring stiffness it’s worth considering two extremes. One is the infinitely stiffly sprung, or solid suspension. Every bump would be transmitted totally to the rider and the ride would be very uncomfortable. Equally, the control of the machine would be difficult because each bump would bounce the machine off the road surface and traction would be lost.

The other extreme would be no better since with infinitely soft springs the machine would sag into the stops.

Somewhere in between is a range of happy compromises. For comfort, springs that can absorb large deflections without transmitting them to the rider would be preferable. For precision of control and minimal variations in the bike’s attitude,' springs that have more limited movement under the same loadings are opted for.

It is therefore necessary to design springs to accomodate a variety of conditions, not to mention machine and rider weights. The process is straightforward provided the designer knows what he wants to achieve. For example, a motocrosser would have a given amount of wheel travel and would be subject to high loadings. Similarly with a short travel road racer.

Steels used in the manufacture of springs have very predictable behavior. Like all steels they are elastic to a certain point; their deflection is linearly proportional to the load applied. The point at which the steel is no longer elastic is called the yield point and shouldn’t be exceeded because the material will be permanently deformed. The yield point can be raised by alloying elements but these are expensive. For normal purposes, oil-tempered steels are suitable but for highly stressed springs such as in motocross, chrome-silicon or chrome vanadium steels are used.

For most conventional motorcycles the suspension springs are used in more or less similar positions and have to conform to certain configurations because of the amount of space available, for example, around the rear wheel and inside the front fork legs. Therefore the outside diameters and overall lengths are approximately the same for any given front or rear spring.

Variables that are available to the designer are the diameter of the spring wire and the number of turns used within a certain installed length. A larger diameter wire will give a stiffer spring, more turns a softer one.

To understand this imagine a loaded spring. Then chop a section across the wire at right angles and separate the two halves. In effect the end load on the spring will be acting through the axis or center line of the spring but the load will be taken at the edge, where the wire is. Since the load will be acting at roughly the radius of the spring it will be tending to twist the wire. In other words there is a torque on it and if the wire could be unwound the overall effect of the end load on the spring would be the same as clamping one end of the wire and twisting the other.

Now. The longer a piece of wire the easier it is to twist it with a certain amount of load. And similarly it is harder if the wire is thicker. The same thing happens with a coil spring; the higher the number of turns in the spring (the more wire used) the easier it is to compress and the thicker the spring wire the harder it is to compress.

The measure of the spring stiffness is called the rate and its unit is pounds per inch (lb./in.) and can be calculated from a simple formula if the diameter of the spring, diameter of the wire and the number of turns is known. Usually, spring design verges on the conservative so that no more than about 60 percent of the yield stress is used when fully compressed. So there is a tendency to use thick wire with a high number of turns instead of thin wire with a small number of turns within a particular spring rate requirement.

If the idea of having a different number of turns in a spring to change the rate seems strange, consider this. Valve springs very often have a similar diameter and wire size as a front fork spring. But since they are much shorter and have only a few turns, they are much stiffer than the long fork spring. Another way of looking at it is that each of the fork spring’s turns has to absorb less energy than the valve spring and so is easier to compress.

In the context of rear suspension springs this means that if you use a spring of the same wire diameter in a certain shock length but with more turns, the spring rate will be softer. In other words, the same amount of load can produce more deflection in the spring.

This is where the rider can come unstuck when switching springs. Since the softer spring can be more easily compressed the chance of the coils being squashed together under high loads so that they are touching is increased. This condition. being coilbound, is very undesirable, not because it will necessarily affect the spring unduly but because the peak loads that would otherwise by absorbed by the spring are transmitted undiminished to the motorcycle frame. This greatly increases the chance of frame breakage.

So it is crucial to ensure that the damper movement is slightly shorter than the spring travel to prevent this condition. Dampers have rubber bump stops that are specifically designed to limit travel.

One of the difficulties of opting for a low> spring rate to provide comfort, particularly on heavyweight bikes, is that the weight of the machine compresses the spring to start with and some travel is lost. Generally to overcome this the spring is given a certain amount of preload when mounted in the damper.

Preload is the amount by which the spring is compressed from its free length to its installed length on the damper. It will be seen, and certainly experienced when you have to apply preload to get a spring into a damper, that there is some force on the spring while it is installed, but the advantage here is that the travel this would have otherwise used is saved for useable spring travel in operation. Invariably when the machine is unladen and standing on its wheels it should just start to move the springs. In addition however, the bump stops on the damper should only touch on the biggest bumps, providing the top limit for spring load.

The same rules apply even for motocross and enduro machines despite the use of much longer travel suspension to accomodate the rougher terrain they traverse. Because the bikes are relatively light compared to road machines, their springs have less preload however.

It’s long been realized that the provision of a light spring rate to provide a comfortable ride and a strong rate for load capacity or in the case of an off-road machine, to provide suspension that can handle small ripples as well as the massive jumps, are conflicting requirements for a spring with a single rate to accommodate.

The answer to this is to use a multi-rate or progressive-rate spring that stiffens as the load increases.

Multi-rate springs can be wound so that a proportion of the turns at one end are closer. As the spring compresses these turns become coilbound so that there are fewer turns actively cushioning the shocks coming from the wheel. You will recall that the more turns the softer the spring, the fewer the turns the stiffer the spring. Initially, when the spring is lightly loaded it has a lower rate and gives a soft ride. However, as the load increases, or if a sharp shock is encountered, part of the spring is effectively removed by being coilbound and the lower number of turns still in action stiffens the spring.

The effect can be made progressive by making the spring so that increasing numbers of turns are coilbound as the spring is compressed.

Another approach is to stack springs on top of each other. The result is the same as for multi-rate or progressive springs, except that confusion can arise as to the role of the smaller spring being added at the base of a longer one.

Because the smaller spring has very few turns, as with the shorter pitch turns on the multi-rate spring it becomes coilbound before the long spring as the load increases. In effect it acts as a solid spacer.

You will recall however that increasing the number of total turns in the spring assembly lowers the spring rate. Thus the initial rate of the two springs together is lower than even the longer of the two springs.

There is a formula that relates the total spring rate to any number of springs placed in series, or end to end. The result is that the final rate is lower than any of the springs’ rates, because there is more spring wire in action. Recall the wire being twisted in torsion.

It may come as a surprise to find that while you might be adding a small spring of what seems to be an extremely high rate, say 160 lb./in., what is important is that it becomes coilbound in only two inches of travel. If your enduro bike already has 80 lb./in. springs and six inches of travel, the maximum load they can take is (80 x 6) 480 lb. But the smaller spring has a maximum load of ( 160 x 2) 320 lb. so you can see that it will be solid well before the maximum load on the larger spring has been reached.

Up to the point at which the smaller spring becomes coilbound, the same load will be acting through and therefore deflecting both springs. Each will be performing as if the single load were acting on them individually. So it is inevitable that by adding two or more springs in series, the deflection will be increased and the ride will be softer.

One of the shortcomings of progressive wound multi-rate springs, particularly when the spring has long travel as used on motocross machines, is that there are limitations on the rate differences throughout the spring’s movement. While one end of the spring has a small pitch between the winding, the other has a considerably larger pitch. This has a similar effect as if you tried to design a stiff spring by using a low number of turns. The spring would quickly become overstressed and would acquire a permanent set with only a small proportion of its potential deflection.

Instead of using high-quality wire, a complex solution used with good results on Yamaha’s latest monoshocks is the use of tapered wire. The spring is progressively wound toward either end but the longerpitch turns in the center of the spring use the thickest wire. These can then take the higher loads without being overstressed. It means that the spring rate can vary by almost 2'/2 times throughout the rear wheel’s movement.

Spring failure is so rare as to be virtually non-existent. However if overstressed springs will adopt a permanent set which shortens their free length and reduces any preload that might have existed.

This is what happens when springs sag after a small amount of use. It is possible that during manufacture compressive stresses are retained. These locally reduce the point at which the steel will yield and the chance of developing a permanent set is heightened. This will not reduce the spring rate, only the amount of preload and the machine’s ground clearance. The easiest way to overcome this sagging is to restore the preload with spacers.

Generally, spring manufacturers won’t allow this to happen but motorcycle manufacturers often let less than satisfactory springs onto the market. Spring material quality can be improved by polishing and wheel-abrasion and if really high stresses are expected (such as in the aerospace industry) shot-peening is used to refine the spring material’s surface where the highest stresses are encountered.

Since the maximum stresses in the spring wire occur on its surface you might imagine that anything that deteriorates the surface structure can have a significant effect on spring performance.

As a rule, painting and protecting from rust will maintain the spring’s performance throughout any motorcycle’s useful life.

Surface treatments such as chrome plating, if not properly carried out, can seriously reduce the spring’s capacity. Hydrogen can soak into the steel from the plating solutions and cause embrittlement of the material. Only soaking the spring at high temperatures can correct this. So if you’re customising your machine remember this.

Making an analysis of your motorcycle’s suspension is the first move in improving it. So if you’ve got a rough rider, or the springs bottom, or both, there’s room to upgrade your comfort and machine’s handling performance. Everyone’s different too, and rarely does a person conform exactly to the Mr. Average most motorcycles on the road are aimed at. Chances are then that your bike could be better sprung.