SERVICE

We welcome your technical questions and comments, and wi//publish those we think are of interest to our readers. Because of the volume of mail received, we cannot return any personal replies. Please limit your "Service" letters to technical subjects only, and keep them as brief as possible. Send them to. "service, "CYCLE WORLD, 1499 Monrovia Ave.; Nev~port Beach, Calif 92663.

CX FORKS

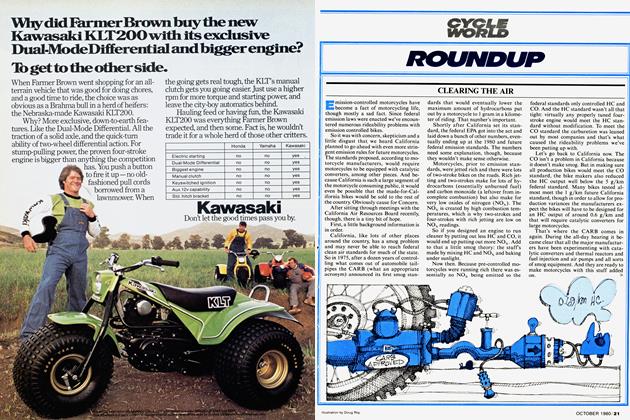

I have a problem that may be common to other owners of middle-weight motorcycles with frame mounted touring fairings—my front suspension. In January of 1979 I had a Windjammer SS fairing installed on my 1978 CX500. In July of last year I noticed the forks had started leaking a slight amount of fluid, so I installed new fork seals, making sure the seals were seated squarely in their bores. At the same time, I installed air caps with a crossover tube and gauge.

Ever since new seal and air cap installation the forks have been significantly stiffen Both compression and rebound damping have been increased dramatically. Front suspension travel, rider on bike, has been reduced by approximately 2 in. Even the travel remaining is quite a bit stiffer than normal. Also, stiction is much higher than normal. Consequently, the fairing bounces up and down noticeably when I ride. Putting air in the forks only aggravates the stiffness. When 18 psi is used, the fork travel is quite a bit greater, but the bike is nearly unrideable because of the tremendous stiffness. One more thing—when I changed the fork fluid the last time, I noticed the upper fork tubes were scratched quite deeply around their lower ends.

I have narrowed the problem down to a few possible areas: (1) The weight of the fairing (approx. 30 lb.) compressing the forks—though this wouldn’t explain the stiffness. (2) Something I did wrong when reassembling the forks. I used 135cc of ATF as specified in the shop manual. Should I switch to another weight of fluid? More or less fluid? (3) The fork springs are worn out. If I bought new stock springs would the

weight of the fairing cause them to wear out prematurely? I have searched in vain for aftermarket springs with a higher spring rate. Does anyone make them for my bike?*.

The CX500 is a marvelous motorcycle, but the performance and part of the fun of riding are being diluted by this front end problem.

Charles Hestand

Grandview, Mo.

Sounds as though you may have too^ much oil in the forks, excessive air pressure under the caps, or possibly a combination of the two. 135cc is the correct amount of fluid for each fork leg, and ATF is the proper fluid to use, but it is possible that last time you changed the fluid not all the oil drained out. Even a slight overfill can cause a substantial change in ride harshness, and using air caps will aggravate the problem by effectively increasing the spring rate and reducing compression space for the air (in effect,increasing the compression ratio in your fork tubes). Release the air pressure, remove the caps and springs and measure the fluid level in the fork tubes. If one is higher than the other, draw out enough fluid to make them equal and try the bike for suspension compliance, without adding air pressure to the forks. If the ride is still rough, try removing more oil in small, equal increments from each leg until the ride improves.

We assume you’ve already tried releasing all the air from the caps, and the ride wat still too rough. If not, reducing your air pressure is a good idea. A pressure of 18 psi is much too high. A range of 10 to 12 psi[ should be maximum, especially on the CX forks, which were not designed to be used

with air caps. Normally, 6 to 8 psi should provide all the rate boost you need.

If lowering fluid level and air pressure is no help, you may have misaligned or bent fork tubes. Removing the caps and springs will allow you to move the sliders up and down and check for binding. If there is a problem, try aligning the tubes as outlined in the Fork Fix article in the Sept, issue.

HONDAMATIC LUBE

As the owner of a 1977 CB750 Hondamatic I am considering using Microlon, a teflon-based oil and gasoline additive in the bike. Microlon is supposed to impregnate bearing surfaces with Teflon particles and reduce wear and friction. They advise that this additive should not be used with metalto-metal friction surfaces in the clutch, but is safe for fiber-to-metal clutches. I know there are clutch plates in the Honda, but I haven’t been able to find out what material is used on the plates, since none of the dealers I’ve talked to have ever had to take one apart. Microlon recommends adding 8 oz. of their product to the crankcase and 4 oz. to a full tank of gas, then running the oil through the normal oil-change cycle. The additive is then supposed to leave residual lubrication on bearing surfaces. So I would like to know what kind of clutch material is in the Hondamatic before I add anything to the oil, so I can avoid clutch slippage problems.

Wayne Martin Ravena, N.Y.

The Hondamatic uses all steel clutch plates, so you do have metal-to-metal friction surfaces. Honda says the Hondamatic clutch operates under very high pressure (600 psi) so that slippage is not normally a problem, but they designed the unit to provide a long trouble-free life on normal motor oil and have not tested additives on the engine or transmission. But if Microlon advises against using the product in allmetal clutches, their recommendation is probably well followed.

THIRSTY F

For some unknown reason the gas consumption on my 1978 Honda 750F dropped 7 mpg. No one locally can figure out why. The only changes made were the installation of a Kerker exhaust system and a Martek electronic ignition. The bike has approximately 14,000 miles on it. I hope you can offer an explanation.

Jim Parsons Panama City, Panama

The Kerker exhaust system shouldn’t cause any decrease in mileage, unless you rejetted and the engine is now running excessively rich. That leaves the Martek ignition. The most common ignition-related cause of poor mileage is retarded ignition.

Check your timing again with a strobe timing light to make sure the advancer is working normally and that the Martek is set up so you are getting full advance (F^ mark on rotating base lined up with static timing mark, which is 40° BTDC) at 2500 rpm and above. The Martek uses the stock 750 mechanical advance mechanism, which can be a source of timing problems when worn or unlubricated. A new advancer may be in order if the original has 14,000 miles on it. The Martek pickup assembly also covers up part of the timing window, which requires you to sight the timing marks at a slight angle when using a strobe. This leaves some room for inaccuracy, so it is a good idea to paint a small dot (yellow works well) on the rim of the rotating advancer plate, directly above the< F mark, so you can be sure the timing marks are properly aligned.

LIMITING REVS

Could you please help me out, as I cannot obtain the information anywhere else^ on a Mallory ignition control kit which allows the rider to set a redline with a. switch to cut the ignition at a certain rpm to prevent over revving: (a) The addressfor Mallory; (b) availability for a 750 Four Honda sohc, or an adaptor kit to make it fit that model, and, (c) the price of the kit.

Nigel Peters

Surrey, England

While Mallory has made rev-limiting* ignition systems for automobiles, they presently have no such option for motorcy-~ ele use. The system to which you may be referring is the RC650A, which was a Mallory Ignition dual-point distributor and magneto originally built for high-performance Volkswagen engines and adapted for motorcycles by R.C. Engineering. R.C. made a magneto drive adaptor which. replaced the alternator and cover and bolted up to the crankshaft on the CB750. This is the system they used on their Sorcerer drag bike. Unfortunately the unit if no longer available because R.C. has temporarily halted production on the drive units, awaiting the release of an improved\ Mallory magneto system now being tested, the Super-Mag II. The earlier model distributors had to be reworked by R.C. in order to withstand high rpm motorcycle* (as opposed to VW) use. The magneto setup has been used mostly in drag racing, speed record attempts or sidecar racing, where the disadvantages of extra width and reduced side clearance are outweighed by accessibility, the simplicity of a selfcontained ignition system, and good volU\ age output at the upper end. In other words, the system is too wide and heavy for road racing or spirited cornering. If you

still wish to contact Mallory Ignition for information on the Super-Mag, their address is: 1801 Oregon St., Carson City, Nevada 89701. The address of R.C. Engineering is: 13300 Estrella Ave., Los Angeles, Calif. 90248.

If you are interested strictly in a system to limit engine revs, rather than magneto ignition, we suggest you check with a company called Rev-Pro Inc., Box 5292, Santa Ana, Calif. 92704. They manufacture a solid-state rpm limiting device called the Rev Stop. The control module is a small black box a little larger than a cigarette pack, with its circuit board embedded in epoxy. It works on any motorcycle engine (points, CDI, magneto, etc.) and uses power pulses going to the coil to measure rpm. The rpm limit is set at one half desired rpm with a push button on the side of the control box. For instance, if you want

10.000 rpm as a limit, you rev the engine to

5.000 rpm using your own tach as a guide, punch the button, and the engine will then rev to 10,000 rpm before it cuts out. The Rev Stop interrupts ignition for one tenth sec., then cuts back in. If the engine is still spinning beyond the pre-set redline, it cuts out again for a tenth of a sec., and so on until the rpm drops to a safe level. Rev-Pro tells us that most tachometers have a substantial lag problem, so riders are often over-rewing their engines even when the tach indicates a sub-redline rpm. List price on the Rev-Stop is $179.00

CB160 BEARINGS

I recently bought a 1967 Honda CB160. There was only one thing wrong with it: one crankshaft bearing was shot. I went to the Honda dealer and they said the entire crankshaft has to be replaced— for S200! Is there any cheaper way to replace the bearing?

Steve Bromley

So. Lyndeboro, N.H.

The CB160 crank is a pressed-together unit with non-replaceable rods and center main bearings. The outer main bearings, one ball and one roller type, can be pressed off, however, and replaced with new ones. The big question is whether the condition of the rod bearings and inner mains warrants the investment of labor and expense on the outer main bearings. High-mileage CB160s typically develop rod bearing problems, both big and small end, so if you have a failing main bearing there is a very good chance that the rest of the crank assembly is worn also. If the bearing failure occurs in one of the inner mains or a rod, there is no choice but to replace the crank.

The cheapest route may be to find a good used crank (as one of our staff did with his own knocking CB160) or locate an entire used engine at a junk yard. E9