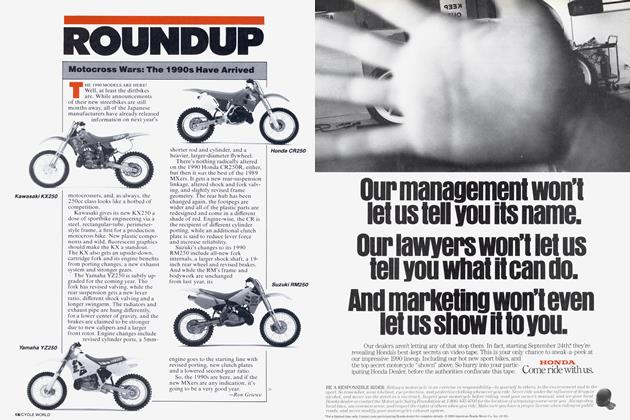

Kawasaki Uni-Trak Motocrosser

A New Approach To Motocross Rear Suspension

Ron Griewe

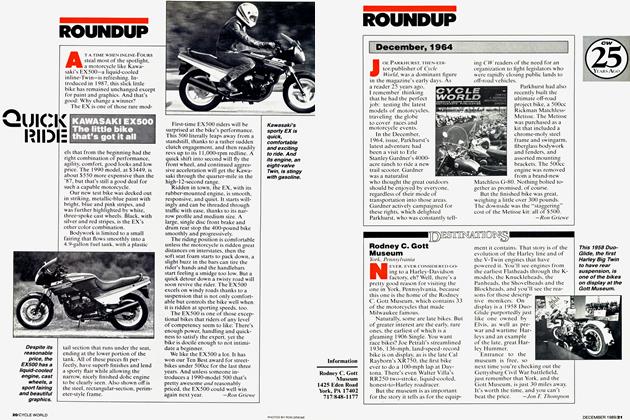

Before Brad Lackey left for Europe. he voiced a great deal of excitement about his new works Kawasaki. It is designed around a single large shock, vertically mounted just behind the swing arm pivot. The design goals were to build a superior rear suspension, keep the center of gravity low and, naturally, give the Kawasaki factory riders an advantage over their competition. The new suspension, called Uni-Trak, looks similar to the design used on Kawasaki's KR250 and KR350 works road racers.

“This Uni-Trak is low and has a low center of gravity,” said Lackey. “You can go through giant bumps and not feel any bottoming out because it absorbs so much.

I don’t know why, maybe because of the size of the spring we’re using. It’s really a humongous heavy spring. You can hit giant bumps flat out and not even tell if it’s hitting bottom. It really works well.” Kawasaki representatives in the U.S. back up Lackey’s evaluation and report that Uni-Trak is good for three seconds a lap; that is, putting any factory rider on a Uni-Trak yields a three-second-a-lap improvement-same track, same rider.

The last really radical departure from conventional rear suspension for motocross machines came in 1974 when Yamaha introduced the Monoshock. The Monoshock has been successful but many have voiced dissatisfaction with the high> center of gravity and tendency for the rear wheel to kick over square-edged holes and ruts.

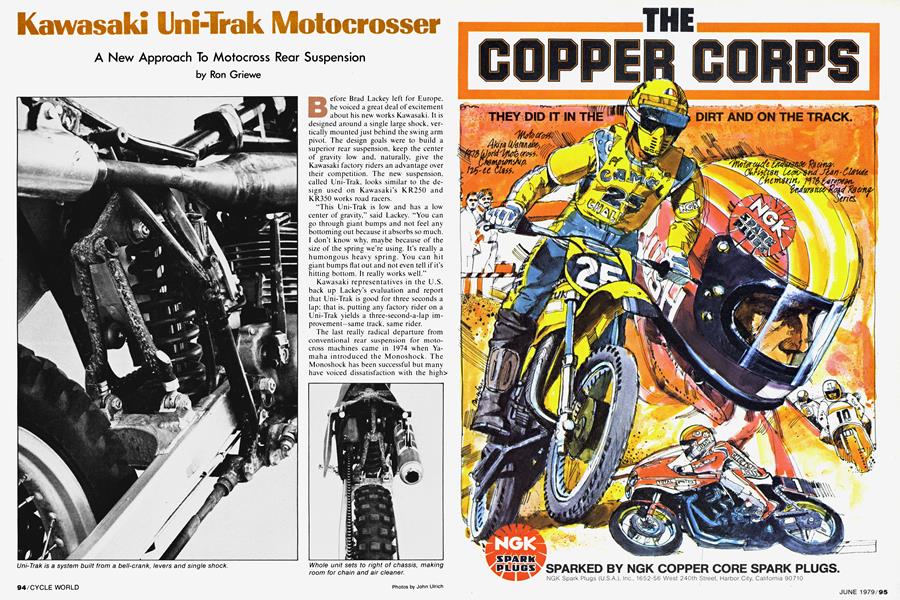

The Uni-Trak design is supposed to eliminate these complaints. A largebodied, KYB DeCarbon design shock (measuring 16 in. eye-to-eye) is mounted in a vertical position just behind the swing arm pivot. The 2-in. diameter shock body is positioned to the bottom, mounted on the lowest part of the frame. Both the position and mounting lower the center of gravity. A flexible hose connects the shock body with a remote reservoir hung on a frame bracket low on the right side of the bike.

The giant shock spring has a 3.5-in. outside diameter, but spring rate information wasn’t available. Internal damping is adjustable to six settings by turning the shaft, similar to other adjustable KYB shocks. Spring pre-load can be changed by turning two spanner nuts threaded onto the shock body. Shock travel is only 3.5 in., but rear wheel travel is over 12 in.

Naturally the design requires a frame designed around the shock. Starting at the steering head, the large-diameter chromemoly steel backbone goes back to the seat/ tank junction, then curves to parallel the seat base. Sub-members and the rear down tubes are connected to the backbone. Little triangulation is used, placed to the rear of the shock. The sub-members hold a bell-crank arrangement, the front of which connects to the top of the single shock. The. center of the top arm pivots in the frame sub-tubing, and the rear has double arms that connect to the swing arm a few inches behind its pivot point. The whole unit is offset to the right side of the frame, making room for an air cleaner on the left side.

continued on page 130

continued from page 97

The swing arm is long (23 in.) and. straight. It is fabricated from box aluminum and sports eccentric axle adjusters, eliminating the need for adjustment after axle removal and furnishing precise chain and wheel alignment.

Front suspension is conventionale KX250 forks with travel extended to 12 in., and 38mm stanchion tubes knurled where they contact the stock KX triple clamps.

The bike shown here was the open class version, with a displacement somewhere between 400 and 500cc. Several open engines will be available to team riders sothey can choose the size that fits the course best.

The first prototype Lackey rode was 420cc, but made too much power. “I can’t" really say what engine size or horsepower will be,” Lackey said. “We’ve changed it around trying to find a good combination., It has plenty of power. The main problem we have is trying to mellow it out .to where it’s got nice and smooth power.”

Engine cases are aluminum and the' swing arm bolt doubles as the rear engine mount. Side cases are magnesium and the transmission has an oil sight gauge. Cylinder and head are aluminum, with a rough' sand-cast finish to improve cooling.

Like most works bikes, the big Kaw had many handmade parts. The pipe is builtfrom hand-shaped steel pieces, the footpegs are machined from billet aluminum with titanium pivots. The folding shift lever is a one-off custom, the silencer has a steel front and internal core mated to an aluminum outer housing, and the Mikuni carburetor has a machined aluminum stay-_ strap to steady it. The bike we checked had> a handmade fiberglass tank but some of the team bikes will use the production plastic tanks from the 250 K.X. Some of the steel parts on the prototype shown here will be replaced with lighter aluminum pieces on the actual ’80 works machines.

These changes will help drop the weight of the open bike to around 215 lb. dry. The’ 250 uses the same chassis as the open bike but has a lighter engine, so projected weight is 205-210 lb. Plans also call for a factory 125 Uni-Trak with its own chassis.

We weren’t granted a ride on the UniTrak but bouncing on it reflected a softly set up suspension.

Will a Uni-Trak Kawasaki and Brad Lackey be World Champions in 1980?^ Could be. At the least, they combine to produce a serious attack force. g]