BEGINNER'S GUIDE TO HELIARC

...Of Arcs, Sparks and Dat Ol' Debbil Oxidation

Mike Griffin

Welding, put simply, is the melting together of pieces of metal. This is easy enough to comprehend. Simple as it may sound, though, there are complexities involved in welding that can defy all but the most experienced and thoughtful welder. And failure to deal with these complexities threatens the thickness of our wallets at least, and well-being of life and limb at most. For example, you would not want to entrust the health of your family to the first yahoo that catches your eye in the yellow pages. But that’s just what can happen when a motorcycle buff who is a family man seeks to get Junior’s pranged minicycle patched up. If he’s like most of us. he has at best a passing knowledge of welding. Sure, he realizes that if a weld has lumps, pits and spatters, if its appearance is generally sloppy, the weld will probably offer less than optimum strength. But even in the case of a tidy weldingjob, what assurance does a layman have that (1) the metal was prepped correctly before welding. (2) that the correct type of welding rod was used, or (3) postwelding treating was done, as is required of many metals? Of course, if the customer doesn't know the welder, his practices and professional qualifications, there are no assurances.

It's a serious matter. And it behooves every motorcycle enthusiast to at least be familiar with the various technical nuances that distinguish a good weld from a bad one.

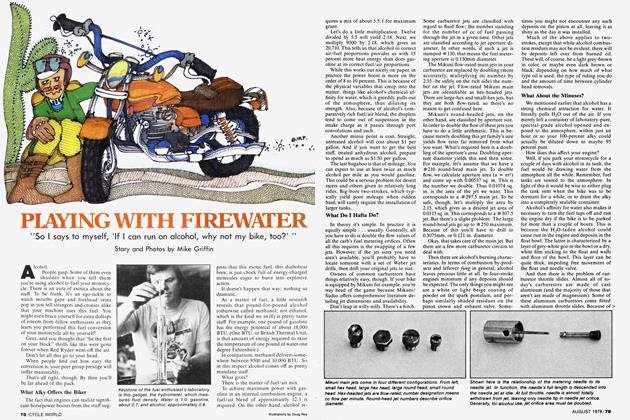

In the coastal community of Venice. California, is a modest business called Fabrications by Jere. Here, at 13425 Beach Ave.. Jere Kirkpatrick and partner Cary McKenzie specialize in prototype and production metal fabrication. Their track record includes the design and fabrication of racing karts, motocross bicycles, marine equipment, motorcycle swing arms (units for the factory Bultaco racers) and off-road vehicle components. In preparing this article, I was impressed with the versatility of skill shown by Kirkpatrick and McKenzie, and sought their assistance. Moreover, both men are ardent motorcyclists, making them privy to the subtleties and bugaboos that only motorcyclists seem to know.

Let's begin with basics.

The American Welding Society defines arc welding this way: “Metal arc welding consists essentially of a localized, progressive melting and flowing together of adjacent edges of base-metal parts by means of temperatures approximately 10,000° F of a sustained electric arc between a metal electrode and the base metal.”

Some Background on the Matter

Currently there are two basic types of arc welding: carbon electrode and metal electrode. In the carbon arc process, the electrode serves only as a source of heat. It sustains an arc but no metal is transferred through the arc stream. Instead, filler material must be fed into the welding zone in rod form, when desired.

Then there is metal arc welding, of which there are two primary methods, differentiated by how the metal electrodes are used. Generally, the term arc welding applies to a process wherein an electric arc raises the temperature of the electrode tip and the parent metal to the point of fusion.

Molten metal from the consumable electrode is then transferred across the arc gap and deposited in a molten puddle on the parent metal.

On the other hand, the heliarc process is based upon using a non-consumable electrode made of tungsten or tungsten alloys. The melting point of such electrodes is about 6170°F. The heliarc electrode does not touch the molten weld metal. Instead it should be positioned over the work, while intense heat from the tip maintains the puddle. Electrode tips contaminated by contact with the weld puddle will cause a sputtering arc if not properly cleaned.

While consumable-electrode arc welding supplies its own filler material, heliarc and other similar processes may or may not require the use of filler material. Generally a filler metal is used except when very thin metal is to be welded.

And what about the old stand-by, oxyacetylene gas welding? Where does it figure in this discussion? Well, it doesn’t. McKenzie, for example uses oxy-acetylene only for cutting metal, saying that heliarc -ing's higher performance offers so many advantages that the comparatively low temperature of the gas torch (6500°F.) is hopelessly outclassed.

Say Hello to Fluxes, Slags and Gases

In the early days of welding (Moissan and De Meritens were two of the first pioneers in the field during the mid-and late-1800s), the quality of welds was understandably limited. One of the main problems was the undesired formation of oxides and nitrides in welds. This was bad for several reasons. Basically, these materials are lacking in ductility and tensile strength. Also, they tend to deplete the parent metal of its normal qualities. And if that’s not enough they often form scums which inhibit blending of the parent metal with the filler metal.

These formations occur because most commercial metals, while being molecularly stable at relatively low temperatures, are very susceptible to the effects of atmospheric gases at welding temperatures. So what’s needed is a method of protecting the molten metal from certain components of the air until the metal cools down past its susceptibility temperature.

An inert gas: that’s what's required.

Eventually, it was found that helium and argon gases perform quite well in this respect, staving off the potentially harmful influences of oxygen and nitrogen while things cool off. Also it was discovered that the combustion of some cellulose materials, either fed into the arc stream or as an electrode coating, provides a protective gas envelope for the weld.

Of course heliarc welding uses no such coated electrode. But it does rely on helium gas, or a mixture of helium and argon, for thermo-chemical protection. Argon gas is frequently used here because (1) it is relatively easy to obtain, and (2) being much heavier than helium, argon provides better shielding at lower flow rates.

As skilled welders, both McKenzie and Kirkpatrick express preference for using two gases only when arc welding, indicating that a blend can yield good, flat welds plus excellent heat manipulation of the parent metal, but without such problems as cold-start weld lumps.

It is also interesting to note that while flow gauges are fitted to gas bottle regulators, highly experienced welders can more easily determine optimum gas flow by listening to nozzle hiss.

In due time, various fluxes were developed. Fluxes are simply fusible materials or gases used to dissolve and/or prevent the formation of oxides, nitrides or other undesirable by-products of welding. McKenzie also tells us that the flux used in some metal-arc welding actually flushes out impurities existing in the molten materials.

And then there is slag, which is the nonmetallic solid material occurring in the weld metal or between the weld metal and the base metal.

But slag is not just another undesirable welding by-product; it serves a valuable purpose. In many types of welding the shielding gas actually solidifies on the weld as slag, and protects the welded seam against contamination during the cooling period.

However, to achieve this goal the slag deposit must be present on the surface of the weld. If it’s within the weld it interrupts the homogeneity of the parent metal and can lead to that ol’ debbil oxidation. So the welder must be careful about this stuff, doubly so when laying down multi-run welds, for the slag must be scrupulously removed from each layer before the next one is started.

Slag inclusions can be avoided. The pool of molten parent metal that forms the crater should be sufficiently fluid, and kept that way long enough for the slag to float to the surface. If for one reason or another this is not done, the chances of a flawed weld increase greatly.

On the other hand, McKenzie points out, you don’t want to cool the metal too slowly because this will increase the hot metal’s vulnerability to the aforementioned oxidation and nitriding. There is indeed a precise balance between heat dissipation and retention that must be maintained. This balance comes from experience. Lo, the aspiring arc welder of the preheliarc 19th century. There he hunkers, gazing at this mini-moonscape of glowing, spattering, hardening metal, wondering how to make some sense of it all. It’s a problem, all right. And without the protective gases, fluxes and slags that were to come along in the 1930s, he’s got a long wait ahead of him. Indeed, it was the stimulus provided by WWI that gave arc welding a sound, progressive shove. Then, a few years after that, technology took a giant step in the form of the coated wire electrode. Up to this time bare wire had been used. This was the main limiting factor in arc weld tensile strength.

The Case of the Coated Electrode

Kjellberg of Sweden was searching for a way to insulate the electrode to improve its overhead use. His efforts were successful and he was granted a patent. Then, in a second patent application he propounded the idea that the electrode-coating substances in the arc stream would do much to eliminate the ambient atmosphere. In turn, Kjellberg’s discoveries led to the development of the two basic types of shielded electrodes: the mineral-coated (or slagging) type, and the gas-forming type. As a consequence, today’s metal arc welders have thousands of different types of coated electrodes to choose from, providing in a single component the protective gases, fluxes and slags essential to efficient welding which welding pioneers needed so desperately.

Of course, modern welders have many factors to consider when choosing an electrode. To begin with, there is the type, position and preparation of the joint to be welded. Then the welder must ensure the ability of the electrode to carry suitably high current values without injury to the weld metal. Next, the mass of work metal must be considered, along with its ability or inability to maintain its properties after welding. And don’t forget the effects and strains, if any, imposed on the welded metal by its exposure to heat. What about pre-heating the material to be welded?> Sometimes it's necessary. The same goes for post-welding heat treating. And then there's cost, of course . . . this stuff's not free.

Photos and illustrations by the author

Oh. just for the record: Coated, consumable electrode, arc welding is otherwise known as “shielded metal arc welding.”

Mig and Tig Welding—A Real Gas

As we have suggested in preceding passages, the use of a protective gas shield can generate its own slag and flux. Well then, the perceptive reader might ask, if it generates its own slag and flux, what’s the point of using a coated electrode? Good point, for there is no point to it, at least in TIG (tungsten inert-gas) welding and most MIG (metal inert-gas) welding. The TIG process uses a single tungsten electrode, which is non-consumable, as an arc source. Welding rod filler may or may not be used, depending on the nature of the job. Shielding comes from a gas or a mixture of gases. MIG welding, on the other hand, is predicated upon a consumable electrode. Shielding here comes from a gas or gas mixture, or shielding may be through a mixture of a gas and a flux, once again depending upon the particular circumstances. Heliarcing is probably the TIG welding process best known to motorcy-clists.

Visual Inspection of the Weld

Even though some welding is subjected to rather exotic inspection processes (X-ray testing, gamma ray radiography, Magnaflux and Xyglo), the vast majority of welding inspection is done visually. Of course, just eyeballing the work will not reveal internal flaws or stresses, so it's not without shortcomings. However, if the general appearance of the weld meets certain standards. it can often be considered acceptable. So. here are some of the traits you should look for. Incidentally, these parameters apply to oxy-acetylene as well as electric arc welds.

(1) Weld beads should be characterized by uniform, fine ripples.

(2) The weld bead should be free of pinholes.

(3) There should be little or no indication of w here new filler material is started.

(4) The weld should be clean and free of spatter, arc scars, slag and excessive oxide.

(5) The weld deposit should be of correct contour.

(6) Weld edges should show thorough fusion and be neither undercut nor overlapped. (7) Welds should not be excessively reinforced.

It is important that they be of correct size.

Want to Know More?

The welder has a responsibility. He should provide you with the best weld(s) possible, particularly if the work is done on structural components, where weld failure could lead to injury or death. But the welding shopper realizes that there are no absolutes, no guarantees. Consequently, he does the smart thing: He educates himself so that while he may not be able to perform the work, he will at least be competent to (1) know what he needs by way of welding and, (2) evaluate the quality of the welding done for him.

Fortunately, there is a wealth of research material available to the interested layman. For example, the American Welding Society has produced many handbooks detailing the various aspects of the field. Some are pretty heavy technically; some aren't. Probably some of the best publications are produced by large corporations in the field. For example. General Electric's Arc Welding Manual ‘ánd the Pocket Welding Guide produced by the Hobart Brothers Company (cost 50C) are very informative. yet reasonably easy to read.

High schools, vocational schools and colleges that offer welding classes almost always have excellent textbooks dealing with welding basics and technology. A book costs a couple of bucks, but what you may realize from this investment might save you financial and physical misery farther down the road. And don't forget the local library, where, incidentally, much of the research for this story was done. It's free and it's quiet. But best of all is a welding shop with personnel that w ill take the time to answer your questions and perhaps demonstrate the various rights and wrongs involved in welding. We were most fortunate in having access to skilled fabricators giving straight answers. But no matter where you get your answers, the effort pays off’well in peace of mind, g