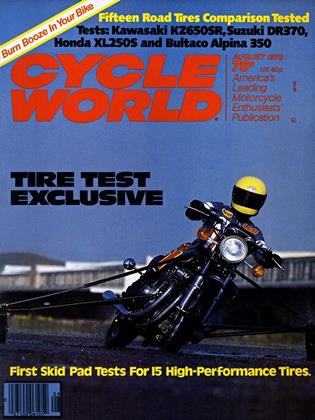

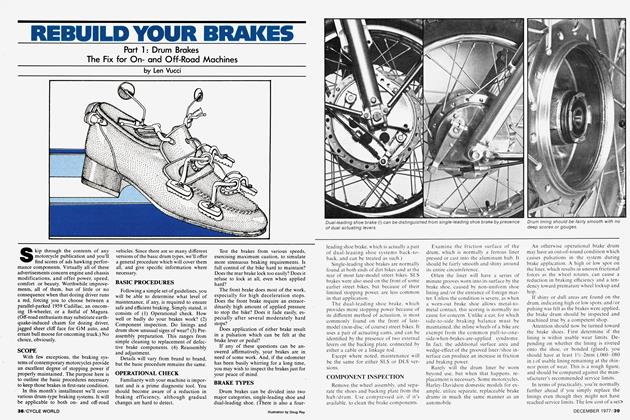

TIRE TEST BREAK-THROUGH

Fifteen high-performance rear tires rated for braking and cornering, thanks to some home-grown engineering

Len Vucci

While on his way to victory circle. a famous racer once was interrupted by a reporter who thought he knew a lot about machines. Thrusting his microphone into the winner’s face, he asked “What sort of tires were you using today?”

The champion had the perfect answer. He said, “Round, black ones.”

That’s a good way not to suffer a fool.

And that’s just about what most of us really know about tires.

Owning a motorcycle means owning two tires. Riding means buying tires, and the average rider buys a tire every year or so.

The choice is seldom based on fact.

We know tires are round and black.

We know there are racing tires, road tires, trials tires and knobby tires for motocross and enduro riding.

We know' that the government and the tire companies working more or less together have made it virtually impossible for any tire maker to sell a really bad model.

We know' the tire companies don’t want to sell bad models. They have competent engineers and designers. They have quality control programs. They have elaborate test labs and equipment.

So much for what we know. All these honest and skilled men, with all their labs and skid pads and instrumentation, work hard and well. They make good tires.

But the tires aren’t all the same.

We can see and read the ads, but paid information usually talks about how' hard the company tries (like the other companies), or tells about the testing (which they all do) or speaks of racing wins (on tires that aren’t at all like what we use on the road), and finish up by saying that they believe their tires are the best (which all the makers believe).

This isn’t to blame the manufacturers. That’s the w'ay the world works.

And it leaves us knowing tires are round and black.

Time to change that. Because all motorcycle owners buy tires, and because CW is frequently asked about brand and model and performance, we decided to conduct our own tests. (As you might guess, the comparison tests that follow' are the first of a series.)

We began by deciding that the rear tire was the logical place to begin, because rear

tires take most of the bike’s force and thus wear out first. We’d need tires for a big machine, for the same reason.

First step w'as to write to the major tire manufacturers and importers. We told them of our intentions and asked for a sample production tire, the one they’d recommend for a high-performance road bike. Fifteen of the firms accepted the invitation.

The test bikes were two Suzuki GS750s, one stock and the other fitted with an outrigger system of our ow n design. (See accompanying article.) Because two of the test tires are designed to not use tubes, we couldn’t use spoke (or wire) wheels. The GS750E comes with cast wheels, w'hich made adapting the rear disc brake, etc., much easier. To further save time, we borrowed ten—two front and eight rearwheels from Lester Wheel Co. All ten checked out nearly perfectly in concentricity and balance tests and fitted both bikes without flaw, which speeded up the testing.

The choice of front tires w;as influenced by timing and availability. Continental and Yokohama were first to express the desire that we use their tires in front, and we accepted. A Conti RB2 was installed on the outrigger bike, and stood up extremely well to hard use. A Yokohama Speedmaster 990 was fitted to the front of the stock bike, and, according to its test rider, “. . . saved his hide more than once”.

The hassle of mounting more than a dozen stiff, new' tires on aluminum rims was reduced by the use of a Rowe Engineering Tire machine. The Rowe machine. which made the dismount/mount process possible without rim scratching, was also used to balance each of the tires and to measure run-out using a dial indicator.

A durometer to measure rubber hardness and an electronic thermometer loaned by # 1 Products rounded out the test equipment.

The site of the performance testing w'as Mobility Systems Inc., in Mira Loma Space Center, Mira Loma, California. The Space Center is home for various testing groups, and offered an abundance of area upon which our testing could be conducted.

The specification table for each tire reflects both information provided by the

manufacturer and measurements taken prior to and during the test sessions. Such items as aspect ratio, number of plies and ply rating, and cord material were provided by the manufacturer. According to DOT standards, the maker also lists the load range of the tire and its maximum carrying capacity. Construction and capacities differed substantially from tire to tire. All but one tire were rated load range B. and carried a four-ply rating. The Cheng Shin, falling in the C range, had a six-ply rating and the highest load carrying capacity.

The remainder of the figures were obtained by measuring the test specimens. The bare tires were weighed, without tubes, on a certified beam scale prior to mounting on the wheels. After mounting the tires on the rims, each was inflated to 28 psi, as recommended by Suzuki, and measured. The diameter w'as taken unladen, as was the width, which reflects the overall distance between the sidewall’s widest points, not the actual tread width.

A meaningful figure for the actual tread contact patch, listed as footprint area, was gained later, during the test sessions. The rear end of the stock bike was lifted off the ground. The tire tread was sprayed with black paint and lowered onto a square of white paper. The test rider then sat on the machine to provide the rest of its operational weight. When the bike was lifted off the board, we had a black print of the tread’s actual contact area. Paint application and elevation techniques varied during testing, as the prints show, but the results were good enough to yield the necessary data.

Each of the tires w'as measured for tread depth. Because of the variety of tread patterns, the only point at which each of the tires could be accurately measured for depth w'as directly in the center of the tread. Since most rear street tires will w'ear the center tread surface away first, this measurement was deemed to be most appropriate.

Next, each wheel/tire assembly was placed on the Rowe tire balancer and balanced, using adhesive weights. Since the imbalance of the Lester wheels was negligible, the amount of weight necessary to balance the tire would be a reflection on the manufacturers’ construction quality. In addition, the tires were rotated on the Rowe fixture, and eccentricity (out of roundness) was measured with a dial indicator. All of the tires were very close to being round, and none of the tires required an excessive amount of balance weight.

We did, however, observe several interesting conditions. When one tire/tube/ wheel assembly was put on the balancer, the side of the tire with the valve stem rotated to the bottom, as it was heaviest. When the tire was rotated on the wheel 180 degrees, so the “light side” dot was opposite the stem, the tire required far less weight for proper balancing. If a tire/ wheel seems to require an excess amount of balance weight, try rotating the tire on the rim. In many cases, this will improve its static balance.

Second, we found that some tubes were partially responsible for a tire’s imbalance, and generally seemed to be excessively heavy around the valve stem. It’s conceivable that changing a tube might affect a tire’s balance, even though the changer replaces the tire in its original position on the rim.

Finally, each of the tires was measured to determine the tread’s surface hardness. Several readings were taken at random points on the tread, and the readings were averaged to yield a single figure. Individual readings for any one tire never differed more than a point or two, which indicated the rubber compound was uniform throughout. One exception was the Pirelli Gordon because of its design. Its tread has a harder compound in the center and a softer rubber on the shoulders, thus, dual durometer readings are given for this tire. Readings were taken again several days after performance testing, and show any changes in rubber hardness between the newand used tires.

As an indication of the durometer scale, several common items were measured for hardness: pink eraser-48; tennis ball-52; wine cork-70; tester’s index finger-38.

TRACK TEST

Subjective track testing and braking tests were conducted on a 0.6-mile asphalt oval located adjacent to, and incorporating part of, the skid pad. The course was actually a modified oval and demanded the use of other-than-classic lines. Debris and the hulks of automobiles destroyed in crash tests at the facility created a chicane in one 85-mph straight; sand and mud washed halfway across the other straight required a tight, inside entrance to one turn. A long series of wooden slats bolted across the inside half of one turn (for car suspension testing) and a pile of gopherdisplaced dirt and gravel on the inside entrance of the other turn meant the rider had to use a late, outside initial apex in one 50-mph turn and an early initial apex in the other. Chain-link fences topped with barbed wire and heavy steel crash-testing

installations located outside turn entrances and exits discouraged crashing. The goal was to push hard enough to test the tires, yet maintain enough margin so that tire slippage could be corrected before a crash.

To make things easier to control, and in the interests of safety, the rider sat straight upright on the bike while cornering, without hanging off. (Correcting sudden slides is very difficult while hanging off to the inside, even though the technique allows faster cornering when good traction exists.)

Tread temperature readings were taken before starting the track test. Then the rider took five laps, pushing progressively harder each lap to scuff-in and warm-up the tire. After being given a five-lap signal, the rider pushed the tire as hard as possible for five more laps, then pitted for tread temperature readings, taken by inserting a thermo-coupling into sipes in the center tread and in the side tread.

Subjective comments were recorded immediately following the 10 laps, covering cornering traction (entering, mid-turn, accelerating hard out of the turn); tire warning at limits of traction; and wheel action in pre-corner braking—a mode which included not only normal front and rear brake use, but also rapid downshifts from fifth to second gear.

Braking tests were then completed on a clean section of one straightaway, using a dye-gun mounted on the right muffler and triggered by the brake light circuit. The rider attempted to control wheel lock-up in stops made—using the rear brake only— from 30 and 60 mph. Two stops were made at each speed, with the best stopping distance used for the test charts. One stop was made from 30 mph with the rear wheel locked. After stopping distances and subjective comments on controllability w'ere recorded, it was time to select another tire and start all over again.

SKID PAD TESTS

When the track test for each tire was completed, the tire was removed from the stock GS750 and installed on the outrigger bike. If things had been proceeding without interruption, delay between track and skid-pad tests would be minimal. But more often than not there was a longer period of downtime between tests. This ranged anywhere from 10 minutes, for just a tire change, to an overnight reprieve for the Metzeler and Nitto. (On the Nankang, which was one of the quickly swapped tires, the center tread temperature actually decreased five degrees during the skid-pad test.)

Just before the cornering test, each tire’s temperature and pressure were recorded and the bike was taken around the skid pad twice to warm the tire. Fast laps were then taken to determine the tire’s tractive capabilities.

The rider would first adjust the outrigger to provide full left lean, about 45 degrees from vertical. In this attitude, weight transfer onto the inside outrigger wheel would unload the bike’s rear wheel, allowing it to slide as the throttle was opened. The outrigger was then adjusted to increase rear wheel loading while the rider simultaneously increased the throttle setting. As the speed increased, the system was then trimmed to allow the bike to lean farther back toward the skid pad’s center.

Eventually, usually with the bike leaned over at an angle which appeared to be between 35-40 degrees, a point of equilibrium was reached. Attempting to increase speed while leaning the bike over farther w'ould cause the rear end to slide out. If the speed was increased while adjusting the outrigger to provide a more vertical cornering attitude, excess weight would be levered onto the outside outrigger wheel. This would cause the rear wheel to lose traction, and also cause the front end to get light. The front wheel would rebel by alternating between biting and slipping, setting up an oscillation which used up most of the fork travel.

We learned the proper technique, at the expense of a nearly-new non-test tire. Two or three laps on the skid pad was then all that was necessary to set up for each tire tested. Almost all of the tires cornered most efficiently at or near the same lean attitude. Additionally, because the rider was free to move around on the bike, corrections in weight distribution could be and were accomplished by a simple shift in rider position.

At the end of the tenth timed lap. the bike was brought into the pits for a temperature and pressure check. (At the test rider’s discretion, additional skid-pad laps were taken if he felt he could legitimately better his time.) As you’d expect, the temperature of each tire’s left shoulder was much higher than that of the tread center. The differences between these temperatures were also more extreme than that caused by the track testing, which more closely approximates the real world. Although a relatively high shoulder temperature was induced by skid pad running, the heat was concentrated near the surface of the tire. This was substantiated by a) the visible decline of temperature while the tire was being measured, and b) an only slight elevation, if any, in the tire’s air pressure.

This shows rather emphatically that tire heat buildup is caused primarily by carcass flex, and not by ground/tire surface friction. It appears that the often repeated warnings concerning proper inflation pressures are valid. This would be especially applicable to the long distance and/or baggage-laden touring rider, who should keep close tabs on air pressure to avoid heat induced tire failure.

From each tire’s skid pad session, top and bottom times were thrown out so that at least six lap times remained. These in turn were averaged, and recomputed to yield speed and lateral acceleration figures for each tire.

At first it would seem that eliminating two or more of a tire’s best lap times would penalize that tire unnecessarily. Not so, for two reasons. First, the test rider’s goal was not merely to get around the pad quickly, but to get around the pad consistently quickly. If the lap times varied substantially, the tire was allowed to cool, and the skid pad test was repeated. Second, the challenge of this skid pad test was not one of going too slow, but of going too fast. Because the skid-pad performance of each tire had to relate to the real world, the rig had to be driven around the course, not ridden in a drift. In an all-out, stopspulled, flattracker-with-training-wheels slide, the pad could be circumnavigated in under YlVi seconds. This works out to a lateral acceleration of nearly 0.8g, a very respectable figure. (For comparison, the 1978 Porsche Turbo, recently tested in Road & Track magazine, corners at 0.83 lg.) But because few two-wheeled motorcycles can sustain such a radical cornering attitude for very long, a flattrackerstyle skid pad test would have been totally invalid for street tires.

What makes this a valid comparison test is that tire adhesion was the factor which dictated skid-pad speeds in each and every case. The outrigger system, w'hile undoubtedly adding several components to the motorcycle equation, made the test much less subject to the variables which would have been introduced by using a conventional, non-outrigged bike.

One area of evaluation which was less easy to define on the skid pad is the degree of control offered by each tire. In general, the rating reflects the performance capability of each tire, as the outrigger system makes for an abrupt grip/slip transition. The ability to control the drift of the tire translates directly into lap results.

The final portion of the skid-pad testing, although extremely important to many of our readers, is less developed than we had hoped it would be. Originally, we had planned to duplicate the entire dry test sequence, including braking. But the illtimed demise of the facility’s water truck, combined with near 100-degree afternoon temperatures and a brisk wind, left us with a %-in. garden hose whose output seemed to evaporate faster than it could be replaced.

Under the circumstances, we had little recourse but to do the best with what we had, or scratch the wet tests entirely. We found, after using most of the paint from the tire-patch block-printing endeavor to mark a 100-ft. (approx.) circle, that we were able to keep a 120-degree arc wet enough to perform some comparative testing.

The procedure was much the same as for the dry skid-pad test,.except that the riding technique had to be modified to obtain consistent times. After leaving the wet area, the tire would retain enough water to affect traction for another 90 degrees or so of travel. Then the dry ground would provide better traction, w'hich, if utilized, would produce higher motorcycle speeds. This w’as fine until the wet ground was once more encountered, whereupon the bike’s front and rear ends w'ould exchange places. To get around the wet/dry

skid pad, the rider had

to determine the

maximum speed which offered traction in the wet, then hold that speed for the necessary rounds. Speed in the dry, slow for the wet was not allowed.

Again, rating of degree of control for each tire reflects the go-fast-without-traction-loss capability of each tire. But at the relatively low speeds at which the test was conducted, the grip-slip transition was less noticeable than it might have been at higher speeds. For this reason we were less critical on this particular rating.

Within the framework of this test, we feel we offer a valid wet-performance comparison. But we cannot say just how' our figures relate to real world, real-rain conditions. We suspect our measurements will apply, but we don’t recommend you purchase your wet-weather rubbers based solely on our test results.

CONCLUSION

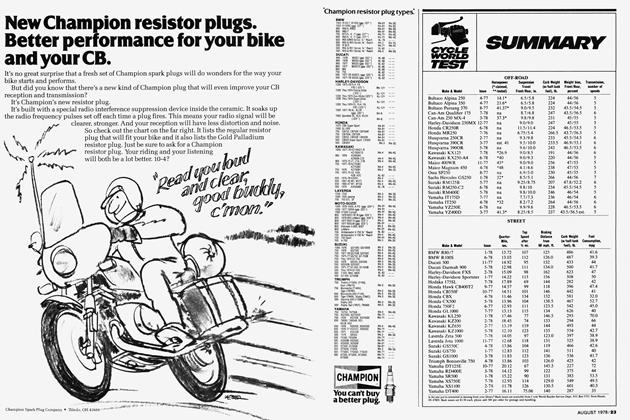

The strongest conclusion to be drawn from this series of tests is obvious: There is a difference, both in subjective evaluation and measurable performance, among the various tires tested.

Some tires worked well in the braking tests and lacked cornering traction. Others cornered well but w'ere hard to control under braking conditions. In a few cases, tires which did poorly in the track tests did very well in skid pad testing. But the best tires cornered, stopped and passed the skid pad test with flying colors, would be the Michelin M-45. Besides turning in the best skid-pad performance both wet and dry, the Michelin placed consistently high in the subjective portion of testing. The M-45 was deemed to possess the best all-round handling characteristics of any of the tires tested.

By comparing the statistics for each tire to the average, median, and mean scores provided, one can get a fairly accurate idea of the relative performance characteristics for each tire. The subjective comments will help fill the gaps, and should leave little in question as to the merits of each tire as tested.

AVERAGE PERFORMANCE

TRACK Braking, 30-0 mph, controlled...71.3 ft. 30-0 mph, locked-up .75.4 ft. Braking, 60-0 mph, controlled 267.5 ft. SKID PAD Lap time, dry, 100-ft. radius 13.61 sec. Lap speed ..............................31.5 mph Lateral acceleration..................0.667 g Lap time, wet..........................9.64 sec. Lap speed ..............................22.2 mph

MEDIAN PERFORMANCE

TRACK Braking, 30-0 mph, controlled......71 ft. 30-0 mph, locked-up......76 ft. Braking, 60-0 mph, controlled .265 ft. SKID PAD Lap time, dry, 100-ft. radius 13.62 sec. Lap speed ..............................31.5 mph Lateral acceleration..................0.665 g Lap time, wet..........................9.65 sec. Lap speed ..............................21.5 mph

MEAN PERFORMANCE

TRACK Braking, 30-0 mph, controlled .71.5 ft. 30-0 mph, locked-up . 73.5 ft. Braking, 60-0 mph, controlled 269.5 ft. SKID PAD Lap time, dry, 100-ft. radius 13.55 sec. Lap speed ..............................31.7 mph Lateral acceleration..................0.675 g Lap time, wet..........................9.64 sec. Lap speed ..............................22.3 mph

As an aid to interpreting the numerical test results for each tire, we’re providing three sets of figures for reference. The average performance figures show the arithmetical average for each category. It was computed by adding each set of figures, then dividing by 15. The median figures represent the center performance number in each category. Seven tires performed better, and seven performed worse in each of the categories. The mean figures represent the average of the highest and lowest scores only in each category. For example averaging the low stopping distance of 61 ft. with a high of 82 ft. yielded the mean of 71.5 ft.

TRACK TEST SUMMARIES AVON

The Avon slipped a little during hard acceleration away from the apex of a turn, and also mid-turn when pushed. Some

lock-up occured in pre-corner braking at the end of straightaways, especially after the tire warmed up. In 30-mph braking tests, the rider had a hard time preventing lock-up during the first stop, but the second stop produced almost no lock-up and a stopping distance 13 ft. better than the first stop. The bike slid straight under fully-locked braking from 30 mph. Rear wheel control in 60-mph stops was good until the last few' yards of each stop, when lock-up occured. Overall performance: Good.

BRIDGESTONE

The Bridgestone showed some tendency toward slippage when accelerating hard out of a turn, but this tire had no mid-turn slip. Braking before a corner, the tire would lock-up and make the rear end of the bike slew around and get slightly sideways. In braking tests, the first 30-mph stop produced lock-up and forced the rider to get on and off the brake. The second 30mph stop produced little lock-up. The locked-wheel 30-mph stop required slight correction to keep the bike traveling in a straight line. Control in 60-mph stops was fair—the rider had to frequently let up on the pedal to halt lock-up, then re-apply the brake. Overall performance: Fair to good.

CARLISLE

The Carlisle slipped under almost all cornering conditions—entering the turn, mid-turn, accelerating out of the turn. The slip was most noticeable when upshifting out of the turn—the rear end stepped out and forced the rider to correct by steering into the slide and wrestling with the handlebars. There was no warning at the tire’s limit before the bike started going sideways. Braking control from 30 mph w'as significantly better in that wheel lock-up could easily be avoided. In the fullylocked-wheel stop from 30 mph, the bike went in a straight line with minor correction required. But from 60 mph. lock-up was difficult to control—the bike left “S” shaped skid marks and the rider was forced to ease off and re-apply the brake to keep the bike traveling straight. However, lock-up controllability was very good in pre-corner braking. Overall performance: Poor.

CHENG SHIN

The Cheng Shin provided fair cornering traction with some slip evident at mid-turn and under hard acceleration. But tire lockup w'as very difficult to control in precorner braking and in other braking situations. There was no warning that the tire was going to lock—it just did. A fullylocked stop from 30 mph w'as impossible.

Whenever the rider attempted such a stop, the bike instantly went sideways. Backing off the brake would allow the bike to straighten up, but as soon as the brake was reapplied, the bike would go sidew'ays in the opposite direction. Since sliding a 750 lock-to-lock on pavement is dangerous, further attempts to complete a fully-locked stop from 30 mph were abandoned. Wheel control in stops from 30 mph and 60 mph was very difficult. Overall performance: Poor.

CONTINENTAL

The Continental offered very good traction in all cornering modes. No slip was evident in mid-turn and while accelerating from the apex. Pre-corner braking was good, with some tendency toward lock-up without causing control problems. In 30mph stops, it was hard to avoid lock-up. The same was true of 60-mph stops: it was difficult to avoid lock-up during the second half of the stop. There was some tendency for the bike to slew around, requiring correction. The bike stopped essentially straight in the fully-locked stop from 30 mph, needing only a little correction. Overall performance: Very good.

DUNLOP

The Dunlop exhibited some mid-turn and exit slip, a condition which worsened as more laps were completed and the tire heated up. Slip was most apparent during hard acceleration exiting a turn, especially following upshifts. During pre-corner braking, the rear wheel tended to lock and> skate side-to-side. Braking control proved to be much better in 30-mph stops. Lockup from that speed was easy to control. The rider could easily find and keep the tire right on the sharp edge of lock-up without actually skidding the wheel—until the last few yards of the stop. The bike stopped straight with slight correction necessary in the fully-locked skid stop from 30 mph. Ease of control resulted in a nearperfect 60-mph stop with no lock-up problems. Overall performance: Good.

FORMULA

The Formula slipped in mid-turn even at steady throttle openings, and slipped so badly under hard acceleration from the turn apex that the rider was often forced to back off the throttle and wait for the tire to grip again. There wasn’t any warning of the point at which the tire would let go and slide. After several laps, road irregularities and bumps in turns would cause sliding even at relatively easy rates of acceleration out of corners. Pre-corner braking control was poor—the tire locked easily, the rear end of the bike often swerving. The rider couldn’t prevent wheel lock-up in stops from 30 and 60 mph. During one stop from 60 mph, the bike went almost full-lock sideways when the rider tried to correct the swerve tendency instead of releasing the brake. Overall performance: Poor.

GOODYEAR

The Goodyear showed some signs of slip mid-turn and also upon hard acceleration and upshifts exiting turns. But the tire provided excellent pre-corner braking control. The rider had no trouble avoiding distracting lock-up when slowing for turns at the ends of straights. In braking tests, lock-up control was good. In fully-locked . braking from 30 mph, the bike stopped straight and required very little correction. From 60 mph, avoiding lock-up was difficult during the last one-fourth of the stop, forcing the rider to back off the brakes at one point, but stopping distances remained respectable. When the tire locked, the bike didn’t slew around or go sideways. The best stop from 60 was a combination of skid/no-skid braking. Overall performance: Good.

IRC

Fitted as original equipment on the Suzuki GS750, the IRC provided very good cornering traction. No evidence of mid-turn slip was encountered. Very limited slip was felt when accelerating hard out of a turn. Control in pre-corner braking was very good. In brake tests, control was good. The bike stopped perfectly straight from 30 mph with the rear tire locked, requiring no correction. Control from 60 mph wasn’t as good, with some locking. Overall performance: Very good.

METZELER

Once the Metzeler warmed up, the rider had to back off the throttle mid-turn to avoid sliding. Some tire drift was felt under hard acceleration, even after the rider slowed down to compensate for the midturn slip problem. On the other hand, the tire was easy to control in pre-corner braking. Control in 30and 60-mph stops was excellent, and the bike stopped straight with little correction required in the 30mph fully-locked stop. From 60 mph, the bike stopped quickly even though the rider had to ease off the brake once mid-stop to avoid locking. Overall performance: Fair to good.

MICHELIN

The Michelin showed excellent performance in cornering, with no slipping or sliding diving into, running around or charging out of corners. Pre-corner braking control was excellent, but the tire showed some tendency to lock in 30-mph stops and required moderate correction in the 30-mph fully-locked stop. Control from 60 mph was the best of any tire tested and yielded the best stopping performance. Overall performance: Excellent.

NANKANG

The Nankang performed admirably in cornering, showing no mid-turn or exit acceleration slip. But tire lock-up was hard to control in pre-corner braking and the bike tended to slew around and get a little sideways, requiring correction. In braking tests from 30 mph, tire lock-up was hard to control during the last part of each stop. The rider was forced to back off the brake during the fully-locked stop from 30 mph to avoid getting completely sideways, and the tire left an “S” shaped skid mark on the pavement. Control from 60 mph was good until the last 20 feet, when the tire locked. Overall performance: Fair to good.

continued on page 98

AVON

Roadrunner

$56.95

BRIDGESTONE

Superspeed 21R3W

$40.23

CARLISLE

ST

$42.50

CHENG SHIN

C-701

$34.00

CONTINENTAL

K112A

$51.94

DUNLOP

K91 Mkll Tubeless

$54.65

FORMULA

$44.95

GOODYEAR

$62.50

IRC

$40.49

METZELER

$51.87

MICHELIN

$47.16

NANKANG

$34.30

NITTO

Len Vucci

$41.65

PIRELLI

$57.40

YOKOHAMA

$37.49

continued from page 48

NITTO

The Nitto slid at every point in cornering, at the entrance of turns, mid-turn, and accelerating out of turns. The tire slipped the most at the transition from braking into the apex to accelerating away from the apex. When accelerating out of turns and upshifting, the tire moved sideways in jerks, making control of the machine’s direction difficult. There was no warning before the sliding started. Pre-corner braking control was poor—the bike often slewed sideways with no warning after the tire locked. Lock-up was hard to control in both 30and 60-mph stops. In 30-mph stops, it was impossible to find the point between maximum braking and lock-up. just as was the case in pre-corner braking. In the full-locked 30-mph stop, the rider had to back off the brake several times, but the bike still went sideways and left an “S” skid mark on the asphalt. Lock-up control in 60-mph stops was a little better. Overall performance: Poor.

PIRELLI

The Pirelli proved to be difficult to rate. Once the tire warmed up, there was evidence of slippage entering turns, going around turns and accelerating out of turns. But unlike other tires tested, the Pirelli seemed to be perfectly happy when hung out to the side and sliding. Because it was easy to control the bike even when the tire was sliding, the rider didn’t feel as if he would crash if he stayed on the gas. In fact, the rider found himself able to push the Pirelli hard in spite of the sliding. However, the tire seemed to get more slippery as the laps accumulated. The tire exhibited some tendency to lock and slither in pre-corner braking. Lock-up control during 30-mph braking tests was fair. The full-locked stop from 30 required moderate correction to keep the bike headed straight. Control in 60-mph stops was good, with no lock-up until the last few yards. Overall performance: Good.

YOKOHAMA

The Yokohama performed very well in cornering, with no mid-turn or exit slip. In fact, the rider was able to roll off the throttle in mid-turn, then slam the throttle open without inducing a rear-wheel slide. Traction during acceleration away from the apex was excellent. Pre-corner braking control was good to very good, as was 30mph braking control. The tire showed some tendency to lock-up in stops from 60 mph, and if not dealt with immediately (through backing off the brake), the bike would slew sideways seriously. Overall performance: Very good.