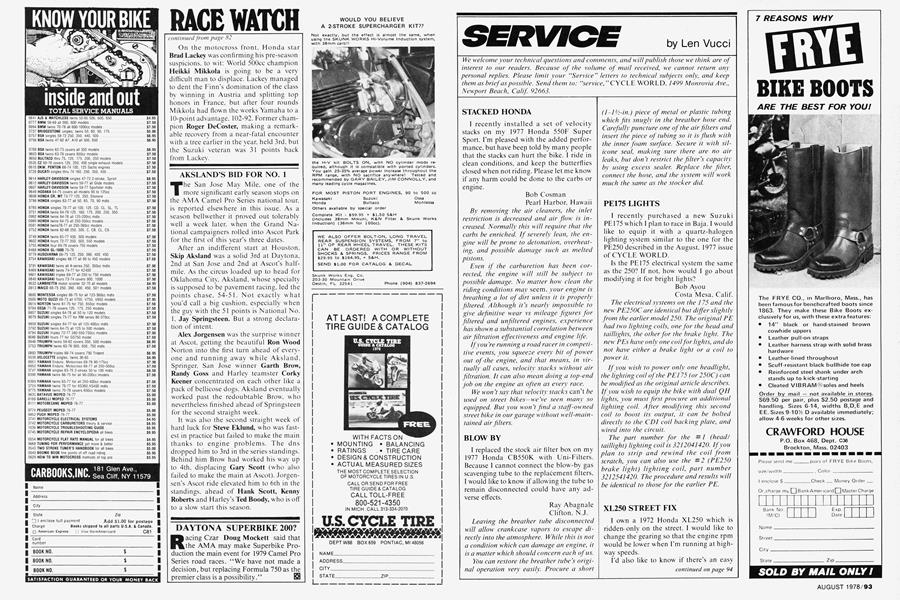

SERVICE

Len Vucci

We welcome your technical questions and comments, and will publish those we think are of interest to our readers. Because of the volume of mail received, we cannot return any personal replies. Please limit your “Service" letters to technical subjects only, and keep them as brief as possible. Send them to: “service, " CYCLE WORLD, 1499 Monrovia Ave., Newport Beach, Calif. 92663.

STACKED HONDA

I recently installed a set of velocity stacks on my 1977 Honda 550F Super Sport. I’m pleased with the added performance. but have been told by many people that the stacks can hurt the bike. I ride in clean conditions, and keep the butterflies closed when not riding. Please let me know if any harm could be done to the carbs or engine.

Bob Cosman Pearl Harbor, Hawaii

By removing the air cleaners, the inlet restriction is decreased and air fiow is increased. Normally this will require that the carbs be enriched. If severely lean, the engine will be prone to detonation, overheating, and possible damage such as melted pistons.

Even if the carburetion has been corrected, the engine will still be subject to possible damage. No matter how clean the riding conditions may seem, your engine is breathing a lot of dirt unless it is properly filtered. Although it's nearly impossible to give definitive wear vs mileage figures for filtered and unfiltered engines, experience has shown a substantial correlation between air filtration effectiveness and engine life.

If you 're running a road racer in competitive events, you squeeze every bit of power out of •the engine, and that means, in virtually all cases, velocity stacks without air filtration. It can also mean doing a top-end job on the engine as often as every race.

We won 7 say that velocity stacks can’t be used on street bikes—we've seen many so equipped. But you won 7 find a staff-owned street bike in our garage without well-maintained air filters.

BLOW BY

I replaced the stock air filter box on my 1977 Honda CB550K with Uni-Filters. Because I cannot connect the blow-by gas scavenging tube to the replacement filters, I would like to know if allowing the tube to remain disconnected could have any adverse effects.

Ray Abagnale Clifton. N.J.

Leaving the breather tube disconnected will allow crankcase vapors to escape directly into the atmosphere. While this is not a condition which can damage an engine, it is a matter which should concern each of us.

Yöu can restore the breather tube 's original operation very easily. Procure a short (I-lVz-in.) piece of metal or plastic tubing which fits snugly in the breather hose end. Carefully puncture one of the air filters and insert the piece of tubing so it is flush with the inner foam surface. Secure it with silicone seal, making sure there are no aitleaks, but don't restrict the filter's capacity by using excess sealer. Replace the filter, connect the hose, and the system will work much the same as the stocker did.

PE175 LIGHTS

I recently purchased a new' Suzuki PE 175 which I plan to race in Baja. I w'ould like to equip it with a quartz-halogen lighting system similar to the one for the PE250 described in the August. 1977 issue of CYCLE WORLD.

Is the PE 175 electrical system the same as the 250? If not. how would I go about modifying it for bright lights?

Bob Ay ou Costa Mesa, Calif.

The electrical systems on the 175 and the new PE250C are identical but differ slightly from the earlier model 250. The original PE had two lighting coils, one for the head and taillights, the other for the brake light. The new PEs have only one coilfor lights, and do not have either a brake light or a coil to power it.

If you wish to power only one headlight, the lighting coil of the PEI 75 (or 250C ) can be modified as the original article describes. If you wish to equip the bike with dual QH lights, you must first procure an additional lighting coil. After modifying this second coil to boost its output, it can be bolted directly to the CDI coil backing plate, and wired into the circuit.

The part number for the #1 (head/ taillight) lighting coil is 3212041420. If you plan to strip and rewind the coil from scratch, you can also use the #2 (PE250 brake light) lighting coil, part number 3212541420. The procedure and results will be identical to those for the earlier PE.

XL250 STREET FIX

I own a 1972 Honda XL250 which is ridden-only on the street. I would like to change the gearing so that the engine rpm would be lower when I’m running at highway speeds.

I’d also like to know if there’s an easy and inexpensive way to improve the headlight output.

continued on page 94

continued from page 93

Bill Johns Brookfield, Wise.

Generally, the simplest way to alter the overall gear ratios is to change either the countershaft or drive sprocket. To raise the gear ratio (lower numerically, fewer engine revs per mile), you’d increase the size of the engine sprocket, or decrease the size of the wheel sprocket.

In the case of your XL, such a change might not he advantageous. The stock final gearing (15T/48T) allows the engine to run at a comfortable pace at highway speeds. Raising the gear ratio would drop the rpm enough that the engine might not run as efficiently, in terms of both performance and fuel economy. You’d be running the engine at a lower point on the torque curve, which would make the bike more sluggish, especially in top gear. It would probably have to be downshifted more frequently, and that would produce an increase in fuel consumption.

If you’re a very lightweight rider, substituting a 16-tooth sprocket for the stocker might be acceptable. But for the majority of riders, the stock gearing should be fine as is.

As for the lights, there is definitely room for improvement. In the June 1978 issue of CYCLE WORLD we provided the method for just such a fix, so we’ll refer you there.

PARTS BREAKDOWN

I would like to pass along a tip to your readers. I rebuild engines and often use Loctite on bushings and sleeves. To remove these parts later, gently heat with a small torch. This procedure softens the bond, letting you remove the parts simply, with no damage.

I have seen too many parts ruined by people not knowing this simple method.

Mark Lukowski Sloan, N.Y.

This is a worthwhile tip which most of us have already learned by trial and error— usually error—and now take for granted. We do, however, wish to add an additional comment: Apply heat carefully to avoid damaging the components you’re trying to disassemble.

And thanks.

HENTER REGULATOR

We’ve been receiving quite a few calls and letters regarding the Henter solid-state voltage regulator tested in our May, 1978 issue. On page 76, we listed as retail outlets several companies which are, in fact, distributors. Beck/Arnley, KK, Rebel, Nichols, and Fox sell only to dealers, and not at the retail level. If you wish to acquire a Henter regulator, you must purchase it from your dealer, who can order the item from one of the distributors mentioned. To those readers whom we’ve inconvenienced, our apologies are offered.

LAVERDA CEASE FIRE

1 own a 1974 Laverda 1000. purchased new. On the day I bought it, the CDI unit failed. Two months later another unit blew out. After nearly four years of part-time service, I’m waiting for the sixth CDI unit from the distributor.

I’ve already talked to the Laverda people, and they say it isn’t the bike’s fault, but of Bosch, who makes the CDI unit.

Is there any way that I can put a CDI ignition from another bike on mine without too much hassle?

Nick Sestito Henderson, Tex.

We’ve received several letters from readers who describe similar problems. This is the first such complaint from a Laverda owner, but the causes and solution are most likely the same as for other bikes. Replacing the stock CDI with a unit from another bike would not be feasible, and to our knowledge would not even be possible without countless hours of adaptation, and much money. Your best course of action is to cure the problem, rather than treat the symptoms.

It is unlikely that you’ve had the misfortune to receive not one or two but five defective CDI units to date. Something external to the unit, and not the unit itself, is probably defective. This could be as electrically simple as a defective ground or an intermittent short or an open circuit in a wire or magneto coil.

Unfortunately, the problem may be so elusive that ordinary inspection methods might not be productive. If you can't locate any obvious physical defects in the ignition wiring or CDI coils, it would be wise to simply replace the original ignition wiring. A factory loom can be used, or if you’re handy at electrics, rewire it yourself to match the stock circuit.

If the new black box subsequently fails, the problem has to be in the CDI’s stator coil assembly, as you will have already replaced the other suspect components. Replacement of this coil assembly would undoubtedly eliminate any further problems.