MAKING KAWASAKI'S SUPERBIKE SUPER PART III

IT’S TIME TO GO PRODUCTION RACING

FERNANDO BELAIR

FOR TWO MONTHS now we’ve been showing you how to develop a stock Kawasaki KZ900 into a faster, better-handling street bike. Our overall target was to take the machine through three stages. First, we made it handle better and ride smoother with just $100 worth of work. Second, we generally threw cost aside and set to work making a top-notch streetable racer utilizing the excellent racing products from Dale-Starr Engineering. In this, our final modification, we are going to show you exactly what goes into the incredibly fast machine that Yvon DuHamel takes to almost uninterrupted victories in Open class Production racing.

As you peruse the list of mods, you’ll probably notice, as we did, that, with few exceptions, the machine that Yvon races is not radically different from the ultimate street Z1 we showed you how to build last month in these pages. In fact, Yvon will race this very same machine at Daytona this year. Then CYCLE WORLD, Kawasaki Motors Corporation and Dale-Starr Engineering will give it away to some lucky reader. To show you what it takes to make a winning Open class racer, let’s pick up where we left off.

The cylinder head work was done (last month) by Dale-Starr Engineering. Once completed, the head was left basically alone. Yvon will use the same ports and valves in his racer that we had on our street Z. Valve sizes are identical. Port sizes are identical. The ports were measured to reascertain their proper dimensions and the combustion chamber and valve faces were repolished.

The Dale-Starr Road & Track cams are not used in Yvon’s racer. They were until now, but new Bonneville cams are being installed for Daytona. The timing of the R&T cams is: intake, 28-58; exhaust, 58-28. Lift of the cams is 8.75mm. The new cams—with their intake timing of 31-61 and exhaust timing of 61-31—have 6 degrees more duration. Lift of the new cams is a hefty 10.62mm. It is important to note here that lots of lift and long duration don’t

necessarily make lots of horsepower. The most important thing in a cam is its profile. How gently it lifts the valves off their seats and how gingerly they are redeposited is the real prerequisite. Having viewed graphic curves of the cam contours, we can assure you that while the Dale-Starr cams are much wilder than stock, they are gentler on the valves than even the stock Z1 cams. And, they make a bunch more horsepower. Also note that the R&T cams may be used with stock pistons and valve springs, while the Bonneville cams may not. Because of the extra strain on the cam chain, a new, all-steel tensioner is used. The stock rubber and steel unit would never last. In fact, we saw some> stock tensioners out of customers’ unmodified engines that were completely shot after only a few thousand miles.

Pistons used for this year’s racer are the very same ones we installed in our street Z. The AMA has increased the maximum displacement in Open Production to lOOOcc. Our racer will displace 994cc. New pistons were installed to “freshen up” the horsepower; they were actually entirely unnecessary, since the old pistons displayed a little carbon buildup but were otherwise unmarred.

When an engine produces as much horsepower as our Z, it naturally generates a lot of heat. The oil that lubricates the engine absorbs much of this heat. To help keep everything at a safe operating temperature, double oil coolers, mounted on a special rack just below the steering head on the downtubes, are utilized.

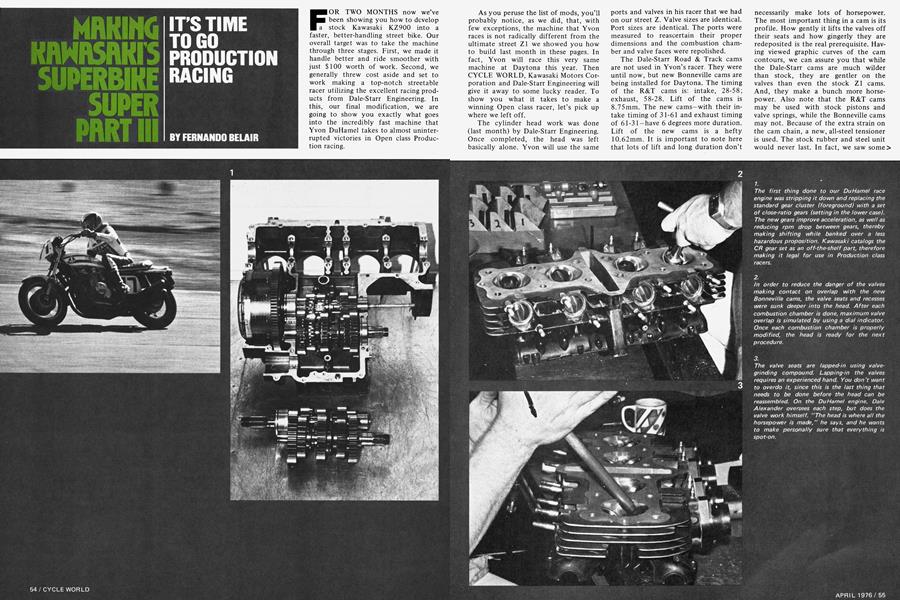

The next modification is one of those that might be considered exclusive to the Yvon DuHamel machine. The standard transmission was removed and a set of close-ratio gears installed. This is legal in Production racing since this particular set of gears is a cataloged Kawasaki part. Not everyone can get a set, but everyone is free to try. The differences in ratios are as follows. Stock CR 1st ......... 3.170 ........ 2.500 2nd......... 2.190 ........ 1.947 3rd..... ____ 1.670 ____ ____ 1.591 4th..... ____ 1.380 ____ ____ 1.380 5th..... ____ 1.220 ____ ____ 1.261

Final gearing was altered from 15/35 to 15/31. According to Dale Alexander’s figures, this computes out to just over 180 mph at 10,500 rpm.

To transmit the power of the engine to the rear wheel, a surprisingly stock clutch is used. Naturally, a fresh clutch is used in the racing engine, but it undergoes no modifications at all. Along with the clutch on the list of unmodified parts go the connecting rods and the crankshaft. All, of course, are assembled with a careful eye, but are otherwise unmodified. A true testimonial to the over-engineering of the Z 1 engine

The final two modifications are new to the DuHamel machine. A recent change in the AMA’s Production racing rules has made them possible. As if the Dale-Starr Z1 weren’t fast enough already, the AMA is allowing a 16-percent overbore on the carburetor throat size, as well as formulating new guidelines with regard to exhaust pipes. The new pipes must look stock, but they are allowed an output of 115 dbA, measured 20 in. and at a 45-degree angle from the rear of the machine. Alexander, whose machines feared few others at the race track last year, calls the new ruling “a license to steal.”

The standard 26mm carbs were > bored out to 30mm, increasing their throat size from 531 mm2 to 707mm2. That is almost a 16-percent pure horsepower increase over last year’s requirements.

The exhaust pipes that came off our machine at the beginning of Phase 2 (last month’s article) were dug up and the headers cut off at 31.75 in. (outside measurement). The mufflers were split down the seams and gutted, with the exception of the small cones at the very ends. Inside the muffler shells go reverse cone megaphones. Of course, they will not be as efficient as straight reversecone pipes—since these megaphones must follow the shapes and contours of the original muffler shells—but they will be far better than the standard mufflers.

That just about covers the engine. With only the jetting to be worked out and the final touches to be put to the pipes before race day, the Dale-Starr people are more than confident that they have enough horsepower to win. But, as we all know, horsepower alone doesn’t always do the job.

The frame is stock, with the exception of the frame kit we installed last month. Starting at the front end, however, there are a number of noteworthy modifications to the machine.

The forks employ standard springs with a 1-in. preload spacer. Damping is supplied by S&W road race damping units which, it should be pointed out, are very different from S&W’s street units.

The front wheel is a Morris Mag, made of magnesium alloy. Disc and bearing carriers are integral and are set up for maximum distance between bearings to give optimum strength to the wheel and minimize axle bending. The front axle is stock. The fork legs are switched left for right and vice versa to locate the calipers for the disc brakes as close to the centerline of the steering head as possible, thereby reducing steering inertia. The top of each stanchion tube is knurled to reduce fork flex under stress. It is not necessary to knurl the fork legs at the lower triple clamps.

Double front discs are used. The discs are aluminum with a sprayed-on liquid steel coating that is Blanchardground to a near perfect finish. The discs are sold by Harry Hunt.

Not only are aluminum discs lighter, but they dissipate heat much better. The front tire is a Goodyear high-profile 3.00-18 (height, not cross-section) made from the A-ll compound. The tire’s construction and cord angles were developed for the speed and weight of the water-cooled Suzukis at Talladega.

All electrical equipment is stock. The electric starter is retained since the kickstarter and kickstart gear are removed and the hole plugged. The alternator cover is cut away for ground clearance and a plate welded in place> once the cutaway is made. The stock gas tank remains in place, as do the standard swinging arm bushings. The original handlebars are trimmed down slightly to reduce steering sensitivity that becomes excessive with the profile of the racing tire. The same reinforced swinging arm from last month’s article is used and the wheelbase is set out as far as possible. When we left the machine, Dale-Starr had not yet received the new Morris Mag which was to be fitted to the rear of the machine along with a new disc brake. These modifications are all possible because of Kawasaki’s new LTD KZ900, which sports both a mag-type wheel and a rear disc brake. Once the AMA approved the LTD, it gave racers the break they needed to install a much sturdier and safer rear wheel on their Zs. The rear tire on the DuHamel machine will also be supplied by Goodyear. It, like the front one, will be tubeless.

Supporting the rear end is a pair of S&W shocks. For Daytona, with its infamous high G-force banking, a set of 145-lb. springs will be necessary.

The final modifications are not only helpful, but essential when dealing with a rider of diminutive physical stature like Yvon DuHamel. Most of the padding in the front portion of the seat is removed. This lets the rider get lower on the machine for reduced wind resistance; it also makes it possible for Yvon to touch the ground when astride the machine at rest. In addition, the passenger pegs replace the original footpegs and are mounted in the upper of the two original peg mounting holes. Natu-

rally, the brake pedal and shift lever arrangements must be modified to fit the new peg location.

And there it is. All that is necessary now is a little good weather, a couple gallons of gas (the DuHamel machine gets 20 mpg at racing speeds), and a smiling, mustachioed Canadian. If the machines continue to be as reliable as they have been, and there is no reason to think different, then the Dale-Starr folks have little to fear. They travel to Daytona confident that victory will once again be theirs. If you entered our Z1 Giveaway Contest, it could also be yours. |Ol

Dale-Starr Engineering 330 Easy St.

Simi Valley, CA 93065

Harry Hunt Discs 1203 Grandview Dr.

S. San Francisco, CA 94080

Morris Industries 3853 S. Main St. Santa Ana, CA 92707

S&W

12268 Woodruff Ave. Downey, CA 90241

Pre-race touchups and complete performance reports on all three stages next month!