ON THE SNELL MEMORIAL FOUNDATION HELMET TEST

UP FRONT

WITHOUT A DOUBT, the toughest and therefore the most beneficial helmet test to consumers is the Snell test. There is no doubt that a helmet that passes is among the best available, regardless of construction, style, etc. Because of this, I think every helmet purchaser should look for the Snell sticker, because it’s really pointless to wear a helmet of either unknown or lesser quality. After all, the whole purpose of a helmet is to save your life.

But just what is the Snell test? How strict is it? If you’re wearing a helmet now, or are planning to in the future, you should know, so here are the details of the latest Snell test that will become effective 1 December 1975. (The following excerpts are taken directly from the booklet “Standard for Protective Headgear 1975,” published by the Snell Memorial Foundation). —Bob Atkinson CONSTRUCTION

A. General

“The helmet shall consist of a hard, smooth shell lined with energy absorbing material or fitted with other means of energy absorption. It shall be strongly attached to a retention system designed to fasten under the wearer’s chin. The assembled helmet shall have a smooth external surface without reinforcing ridges or other rigid external projections greater than 7mm above the outer surface of the helmet, unless smoothly faired so as to offer no significant frictional resistance to tangential impact forces. A goggle clip may be used at the rear of the helmet if desired, and a ledge may be molded at the front edge to support a visor. Such ledge, if included, shall not project more than 10mm from the outer surface of the shell, and shall not extend more than 120mm from the midpoint in front towards either side.

B. Shell

“The shell of the helmet shall be as nearly uniform in thickness and strength as is possible using normal manufacturing methods. Ventilation holes, if used, shall not exceed 13mm in diameter. The heads of rivets, if used, shall not project more than 2mm above the outer surface of the helmet and shall show no sharp edges.

C. Materials

“The materials used in the manufacture of the various parts of the helmet shall be of durable quality, i.e., their characteristics shall not undergo appreciable alteration under the influence of aging or of the circumstances of use to which the helmet is normally subjected, such as exposure to sun, rain, cold, dust, vibration, solvents, and cleaning agents, contact with skin, effect of heat or products applied to the skin or hair. Appropriate tests for durability under these circumstances may be instituted. Materials commonly known to cause skin irritation or disease shall not be used for those parts of the assembly which come into contact with the skin.

D. Finish

“All edges of the shell shall be smooth and rounded and there shall be no metallic parts or other rigid projections on the inside of the shell which might injure the wearer’s head

in the event of impact. No part of the protective components of the helmet shall be inadvertently detachable, nor detach under test impact.

RANDOM SAMPLE TESTING

1. Conditioning for Testing

“a. In addition to testing at ambient temperature, a second helmet shall be conditioned by being exposed to a temperature of -10 degrees C plus or minus 2 degrees C for not less than 4 hours nor more than 24 hours, in a mechanically cooled apparatus.

“b. Heat. A third helmet shall be conditioned by being exposed to a temperature of 50 degrees C plus or minus 2 degrees C for a period of not less than 4 hours nor more than 24 hours.

“c. Water immersion. A fourth helmet may be conditioned by immersion in water at a temperature of 25 degrees C plus or minus 5 degrees C for a period of not less than 4 hours nor more than 24 hours.

“d. All testing shall begin within five minutes from the time of removal from the conditioning equipment.

2. Extent of Protection

“The extent of protection and the areas of the helmet subject to test shall be referenced to the anatomical or basic plane delineated on a standard head. This is defined as a plane at the level of the external auditory meatus and the inferior margin of the orbit.

A test line shall be marked on the helmet subjected to tests. This test line shall be parallel to and 60mm above the basic plane as above defined, save in the posterior one third of the helmet, at which point the test line shall be on the basic plane.

3. Test of Retention System.

“a. The helmet shall be placed upon a test head form with the chin strap fastened over a device approximating the shape of the bony structure of the lower jaw. This shall consist of two metal rollers, each 12.7mm in diameter, at a distance of 76.2mm separation on center, which would serve to represent the jawbone.

“b. A 136kg weight or tension equivalent thereto shall be applied to the device retained by the chin strap. The strap and its attachments must support this weight without parting and without greater than 25mm increase in the vertical distance of the chin strap from the helmet crown.

“c. The test is designed to test the chin strap harness assembly only.

4. Penetration Test

“The complete helmet shall be placed on a rigidly mounted spherical head form which shall be covered with an electrically conductive material. If the helmet to be tested contains a sling or other adjustable sizing component, it shall be relaxed to its most extendable position.

“The penetration test shall be conducted by dropping the penetration test striker onto the outer surface of the helmet anywhere above the reference plane, in a direction essentially perpendicular to the outer surface of the helmet. At least the tip of the striker shall be electrically conductive.

(Continued on page 90)

Continued from page 4

“When tested in the above fashion, the helmet shall be rejected if demonstrable electrical contact is made between the penetrator and the conducting surface of the head form.

“Conditions of penetration test. The weight of the penetration test striker shall have an included angle of 60 degrees plus or minus 0.5 degree, and an altitude of 38mm plus or minus 0.38mm. The radius of the striking point shall be 0.5mm plus or minus 0.01mm. The hardness of the striking tip shall be 60 Rockwell (scale C) plus or minus 3 points. The height of the fall shall be 3mm plus or minus 15mm.

5. Shock Absorption Test.

“Shock absorption shall be measured by determining imparted acceleration to an appropriately instrumented standard head form dropped in guided fall upon a fixed, rigid steel anvil. Each helmet shall receive two impacts in each of four sites. The impact sites shall be at any point above the test line and separated from each other by a distance not less than 1/6 of the maximal circumference of the helmet.

“Two anvil configurations shall be used: one flat, the other hemispherical. Paired impacts shall be applied with each configuration. The flat impactor shall have a minimum surface of 0.127m2, i.e., 127mm diameter face; the hemispherical impactor shall have 48mm plus or minus 0.5mm radius.

“The test head form shall be of low resonance magnesium alloy.

“For each helmet the calculated total impact energy shall be 1000 J as established utilizing the basic drop test mass of head form and supporting arm without helmet, and as confirmed by measured impact velocity.

“At each test locus the initial and second impacts under this requirement shall be 140 J and 110 J respectively. (The actual test impact energy with helmet included as part of the drop mass will be somewhat greater. For example, with a 1.3kg helmet, each test locus will be subjected to approximately 311 J impact energy.)

“Appropriately sized head forms of similar configuration shall be used for helmets of differing sizes. The impact energy in all cases shall be as above noted, related to the test drop mass without helmet. With none of the several sizes of head forms shall the total mass of the supporting arm and test head, without helmet, exceed 6.5kg.

“Any recorded peak acceleration of the helmeted head form exceeding 300g shall be cause for rejection of the helmet.” _

View Full Issue

View Full Issue

More From This Issue

-

Letters

LettersLetters

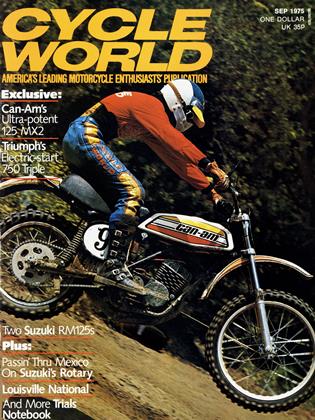

September 1975 -

Departments

DepartmentsFeed Back

September 1975 -

Departments

DepartmentsRound Up

September 1975 By Joe Parkhurst -

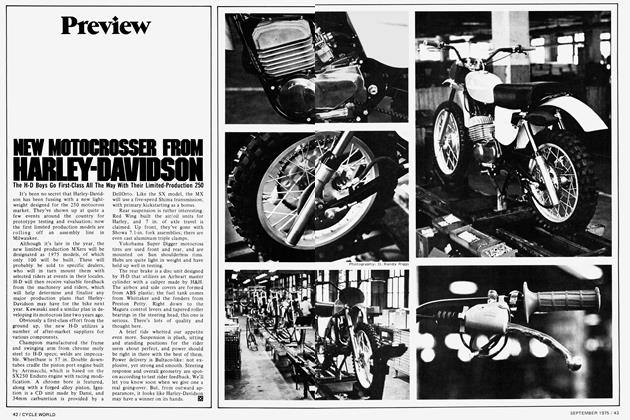

Preview

PreviewNew Motocrosser From Harley-Davidson

September 1975 -

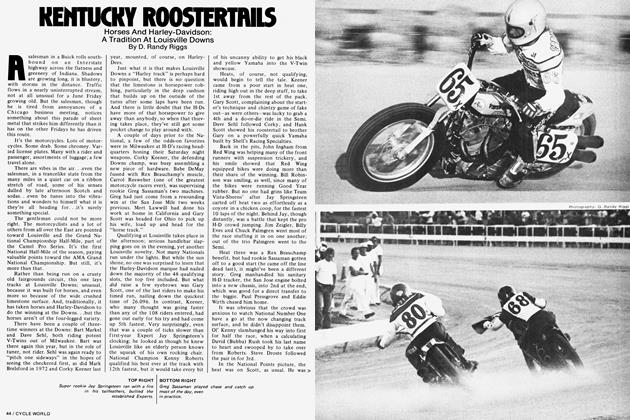

Competition

CompetitionKentucky Roostertails

September 1975 By D. Randy Riggs -

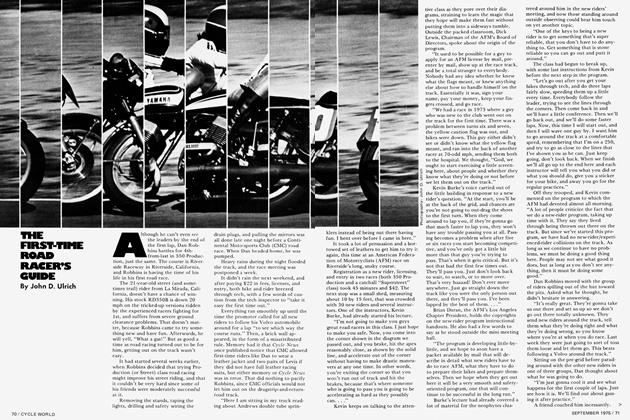

Features

FeaturesThe First-Time Road Racer's Guide

September 1975 By John D. Ulrich