The Armchair Motorcyclist's Handy-Dandy Formula Sampler

Some Mathematical Methods For Expressing One Lie In Terms Of Another

Dan Hunt

MATHEMATICS MAY seem to be formidable to many people, but it is an indispensable evil of a machine age. For the motorcycle enthusiast, or the potential buyer, a passing knowledge of applicable mathematical formulas can be downright useful. It can keep you from being hoodwinked, help you win races, settle arguments, and expose the biggest liar at a railbird meeting.

As an example, a guy could shuck you with a phrase like "This bike will do 125, as she sits right here." Now, if that bike happened to be a showroom stock Sportster, you'd know he was shucking you. With standard gearing, a Sportster would be way overrevved at 125 mph and would need much taller gearing before it could reach that speed.

With the proper formula and a few facts, you could know exactly what speed the bike will attain in any gear.

Power to weight ratios, gear ratios, brake swept area, piston speed...these are all useful tools for evaluating motorcycles, maintaining them, and preparing them properly for the job.

Some of the formulas I'm giving you here are part of CYCLE WORLD'S road testing weaponry. We rely on them heavily, because numbers don't He. Granted, what you feel subjectively about a motorcycle is a certain form of truth. It is as valid as your own power of judgment. But your judgment may be enhanced by an understanding of what those unemotional numbers mean. Numbers are part of the whole picture of motorcycling, which is why CYCLE WORLD introduced a complete set of impartial computations and measured performance data to the motorcycle enthusiast, and was the first magazine to do so in the United States.

PISTON SPEED: Piston speed is a rule-of-thumb index for gauging potential reliability of an engine. Traditionally, 4000 feet per minute has been the reliable limit, but in certain cases, recently introduced technology has raised that to about 4500 fpm. Normally, you calculate piston speed at the engine's peak output rpm, or at the manufacturer's recommended "red line," or rpm limit. You must also know the stroke in inches.

(P is piston speed in P = SxR feet per minute, S is ~6~ stroke in inches and R is revolutions per minute.)

POWER TO WEIGHT RATIO: This is usually expressed as pounds per horsepower (Ib./bhp), and is useful in that it relates the weight of a vehicle to the work producing capability of its power plant. The heavier the vehicle, the more power it needs to produce the same amount of acceleration. For example, the Kawasaki Mach III and the Moto Guzzi both claim 60 bhp. Yet it is rather obvious which machine is going to run faster and quicker.

When you calculate Ib./bhp on a motorcycle, you should add the weight of a rider (either your own weight or a hypothetical "average" weight like 150 lb.). Naturally, if you are trying to correlate Ib./bhp to a specific performance event, one that has been actually measured, you will want to add the weight used during the event, rather than a hypothetical rider weight. What you get is what we call "test weight," and you simply divide that by the horsepower figure (which, hopefully, is honest).

X —W (W is weight, P is — horsepower and X is p the resulting ratio.)

GEAR RATIOS: This tool is often misused in the motorcycle industry. One racing shop manager we knew some years ago thought that you added them via fifth-grade arithmetic to arrive at what was really a multiplication. Gear ratio computations always involve multiplication or, working backward, division. A gear ratio basically is the relationship between the number of teeth on two engaging sprockets; this is true whether one gear drives directly on another, or indirectly by chain.

If you aren't given gear ratios in a specifications manual, you may find them by counting teeth. If you have 25 teeth on the driving sprocket and 44 teeth on the driven sprocket, the ratio is expressed decimally as the value of the number of driven teeth over the number of driving teeth. The result of 44 over 25 is 1.76. What you get is called a gear ratio. As the number gets higher, the gear gets "lower." The higher the gear ratio, the slower the driven sprocket turns in relation to the driving sprocket.

In the sample cited above, a ratio of 1.76 means that 1 turn of the driven sprocket requires 1.76 turns of the driving sprocket.

To compute driving speed from the driven speed, you multiply the driven speed by the gear ratio. To compute driven gear speed from driving gear speed, you divide the driving gear speed by the gear ratio (or multiply driving gear speed by the reciprocal of the gear ratio).

Just remember, multiply output times ratio to get input. Or divide input by ratio to get output.

Ratio = output gear teeth input gear teeth

GEAR RATIO STAGES: There are three stages of geared reduction in an engine/transmission assembly. The engine has a primary ratio reduction of speed from the power output at the crankshaft to the input at the gearbox. Then, depending on which gear is selected, the gearbox internal ratios reduce shaft speed even farther. The final (often called secondary) ratio reduction takes place between the gearbox output sprocket and the rear wheel sprocket. Very important is the term overall ratio, for from it you may relate the engine speed of a motorcycle in rpm to its actual speed on the road. Overall ratio is the only ratio of all these ratios that you need to have, as it is a multiplication of primary, internal and final ratios. You'll note that there is an overall ratio for each gear in the gearbox. To compute overall ratio:

0 RPXRXRf (0 is overall ratio, R~ is primary ratio, R is internal ratio, Rf is final ratio.)

ROAD SPEED/ENGINE SPEED: To relate the rpm your > engine is turning to the speed it is traveling in miles per hour requires that you know the overall ratio for each gear in your gearbox and the circumference of your driving wheel and tire.

Remember, overall ratio only gives you the relative number of rotations of the rear axle in relation to a given number of rotations of the engine. The circumference lets you know how far your machine travels in one rotation of the rear axle.

One good way to find this out is to mark your back tire with chalk at the point where it touches the ground. Mark the ground at that point. Then walk the bike, unladen, in a straight line. When the tire mark goes up, around and back to the bottom, the distance the bike has traveled is equivalent to one axle rotation.

However, to ensure accuracy, go through 2 or 3 more revolutions. When the tire mark reaches the lowermost point, mark the ground. Measure the distance from the starting point. Divide by the number of wheel rotations to get back to distance traveled per axle revolution.

Now you've got some juggling to do in order to match up your terms. You know engine rpm, but that is revolutions per minute. You know the overall ratio. You know circumference, but that is in inches, and the desired figure is expressed in miles per hour.

First get the wheel revolutions per mile (Wm) by converting that wheel circumference figure to feet and using this formula. Wm - 5280 ft.

circumference in ft.

Thus, at any given engine speed in rpm the formula to obtain miles per hour is:

MPH =

rpm x 60 overall ratio

The number 60 is included in the formula to convert revolutions per minute to revolutions per hour. Step by step: 1) multiply rpm times 60; 2) divide by the overall ratio; 3) then divide by wheel revolutions per mile.

You may rearrange the formula slightly to accommodate slide rule calculation, by expressing the gear ratio as a reciprocal and then multiplying instead of dividing.

rpm x 60 1

— Wm x overall ratio

AREA OF CIRCLE: Okay, okay, so I'm getting too far out! Most people know this formula, which at times has been used as the nickname of well-known automotive and motorcycling technical writers. Everybody knows good ol 'pi times r squared, right? It is expressed:

A — Tr r2 (A is area, 7r is 3.1416, r is the radius.)

Keep this formula in mind, for it is a partial step used in calculations for engine displacement, and swept area of a disc brake.

This formula's alternate expression is probably more useful, as it takes the diameter as a basis for calculating area. Since a cylinder bore measurement or a brake disc measurement is given as a diameter, you can crank it directly into the following variation:

A = 1/4 77 D2 (D is the diameter.)

CIRCUMFERENCE: The circumference of a circle is one step in the calculation of drum brake swept area. Simply, it is the value pi (3.1416) multiplied by the diameter.

C — TT D

SWEPT AREA (DRUM BRAKE): The swept area of a brake is a useful measure for predicting how effective a motorcycle's brakes are going to be. Front brake swept area is particularly important on a road machine, for it is this brake which does the most work when you're out there really getting it on.

This one's quite simple. Work out the circumference of the drum from the inner diameter along which the brake shoe rubs, and then multiply that circumference by the width of the shoe.

(A is swept area,

As= CxW C is circumference,

W is shoe width.)

SWEPT AREA (disc brake): Computing the swept area of a disc brake is more involved. For one thing, the calipers of a disc brake work on both sides of the disc. And, the brake pucks do not sweep over the full area of the disc.

So let's keep it simple. Measure the diameter of the outermost limit of the puck's sweep, and then measure the diameter of the sweep's innermost limit. Operation of the brake will leave clear outlines you can measure. Subtract the innermost area from the outermost area. Then multiply this result by 2. In formula form it looks like this:

As is swept area, A0is the Ag _ 2 (A -A ) outermost limit of puck sweep, A, is the innermost limit of puck sweep.)

TOTAL SWEPT AREA: For this you merely add the separately computed swept areas for each brake.

A = As1 + A s2

BRAKE LOADING RATIO: This is the relationship of machine weight to the swept area of the machine's brakes. Like the power-to-weight ratio, it is a useful figure to compare with that of other machines for a rough indicator of a motorcycle's stopping potential.

Naturally, fade and brake lining efficiency are important other factors in stopping quickly. But given a certain level of technology, there's only so much you can do for a machine with excessive brake loading.

To compute brake loading, you take the weight of the machine plus the weight of the rider, or a hypothetical rider, and divide the total by the swept area.

The answer is usually expressed in pounds per square inch.

Ib./sq.in. = test weight/total swept area

DISPLACEMENT: If you have the bore and stroke of a machine, plus the number of cylinders, you may calculate its displacement. Displacement is expressed in cubic somethingor-others, depending upon whether you are a big bore rider and are proud of cubic inches, or a rider of something more subtle and therefore like the comfort of the extra digit in cubic centimeters.

While the metric system is the way of the future because it measures everything in multiples of 10, common usage has made the metric system unnecessarily complex in regard to displacement.

Bore and stroke is expressed metrically in millimeters, yet displacement is expressed in centimeters. As displacement, a form of volume, involves a three-dimensional multiplication, you can misplace decimal points if you aren't careful. So, to simplify things, always remember to convert bore and stroke from millimeters to centimeters. Then you don't have to shift decimals in the result.

V = 1/4 Tr B2S (Volume = (1/4) (?-) x (Bore2) x (Stroke)

STEP BY STEP: In inches, derive area of the cylinder from the bore, and then multiply the result by the stroke. In millimeters, convert millimeters to centimeters by dividing by 10, get the bore area in square centimeters and then multiply by stroke to get cubic centimeters.

COMPRESSION RATIO: I am including compression ratio in this sampler as a prime example of something totally useless to the average motorcycle owner. It is a deceitful parameter, which may indicate anything you want it to at a given time.

In its most common form, it incorporates two factors. Call them Vt and Vc . Vc is the combustion chamber volume when the piston is at the top of its stroke. Note that the combustion chamber is irregularly shaped and that the piston may project into the chamber space.

Thus, Vc is determined only with a great deal of bother-most often by injecting a light grade of oil through the spark plug hole (remember, at TDC) from a graduated container until the chamber is full. By this time, you'll wish you'd believed your owner's manual.

Once you know Vc , then you may calculate Vt by adding Vc to the displacement of your machine. The other way, of course, is to set the piston at the bottom of the stroke, but this introduces complications and requires too much oil.

The equation complete is:

(Cr is the compression ratio, Vt

C = V / V 's total of comkustion chamber 1 c volume and displacement, and Vc is combustion chamber volume.)

So what do you have now that you have it? An approximation which may be used to allude to performance in a vague way, or even more vaguely predict whether or not an engine will ping on regular gasoline. A compression ratio of 8.5:1 in one engine is not the same as 8.5:1 in another engine, for what you are saying in the words "compression ratio" is that you are compressing the fuel charge to a fixed pressure above atmospheric pressure.

But depending on the natural operating temperature of an engine, the materials used for it, its cam or port timing, how well it is assembled, and the rpm at which it is running, the actual compression at the top of piston stroke will vary wildly.

If your calculated truth comes to within 20 percent of reality you are fortunate. So we suggest that you do not rely upon compression ratio as a sole predictor of engine behavior.

POWER/D ISP LACEMENT ("TWEAK") RATIO: This is an interesting rule-of-thumb method for 1) determining how much an engine has been tweaked and 2) gauging the technology of one era against another. A trialer won't have much power in relation to its displacement, as the thing must be a docile creature at crawling speeds. A touring roadster will be midway along the scale in the compromising interests of good performance vs. reliability and decent gasoline mileage. A road racer will be tweaked even harder because you don't care about gas mileage unless you are Yvon DuHamel on a Kawasaki at Talledega. And a dragster will be tweaked to a nerve-wracking level because gas mileage is totally irrelevant and reliability is measured in small dollops of 10 seconds a run.

There are two ways to compute a power/displacement ratio. If you are a balding hot rodder you compute ii as horspower per cubic inch. If you are slightly snobby and

desirous of scoring points with the effetes, you let your wrist go limp and speak of horsepower per liter. So whatever your druthers, you do it thusly:

(tweak = horsepower or ratio displacement)

You'll note that when you express the displacement in cubic inches, the result is bigger numerically than if you express it in cubic centimeters, and therefore more impressive. However, metric system buffs can retaliate by expressing the tweak ratio in horsepower per liter, which, in the case of some small quarter-liter (remember, keep your wrist limp) twostrokes, is overwhelming.

DESTROKER'S FORMULA: This formula has nothing to do with the inside of an engine. Actually, it applies to situations where a guy is stroking you and you don't believe him. It's one of my favorite formulas, therefore. And it looks impressive as hell.

^ ^vyFj T’ ^w2/p2

Now, if I say that T equals terminal speed in the standing start 1/4-mile, and that W equals test weight and P equals rated horsepower, a few automotive engineers will nod in sentimental recognition of a rough way to determine bhp from a vehicle's actual performance. The equation requires that you know the speed, power and weight factors of a second vehicle; hence the T| and T2 and so on.

You'll also recognize the W/P relationship of each vehicle as its power-to-weight ratio. The cubic root factor is a rough way to take into account such things as rolling friction and frontal area.

In effect, the equation says that the 1/4-mHe terminal speed of a vehicle from standing start is more or less inversely proportional to the cube root of its power-to-weight ratio.

Involving a second vehicle in the equation gives you a basis for comparison and computation. When I first saw this equation, I didn't really believe it until I took several machines and ran their data panel statistics through the equation. So far, when the bike's claimed bhp rating has been reasonably accurate, the error hasn't been more than 3 or 4 percent on machines capable of 85 to 105 mph in the quarter-mile.

Another useful application of this formula is to derive an approximate power output estimation from a motorcycle's actual performance. To do this you work backward to get W/P and then solve for P.

In this manner, using two machines in the equation, you may find the horsepower rating of one machine expressed in close relation to the method used by another manufacturer for claiming horsepower.

As you've probably noticed, all manufacturers do not use the same scale of reference when describing the power output of their products. Perhaps they think that it is to their benefit to create their own unique reference systems. Frankly,

I feel that exaggeration of this sort is more of a detriment to public relations than it is a possible sales booster.

Some companies apparently agree with my view, for they have stopped claiming bhp altogether. This is unfortunate in a way, for a correct bhp rating is a valid piece of information. That is, until the claims get so fallacious and unrelated that the horsepower rating loses all information value.

In effect, the "Destroker's Formula" is helpful here, for it may be used to express one lie in terms of another.

And that, in effect, has been the purpose of this article, joj

View Full Issue

View Full Issue

More From This Issue

Current subscribers can access the complete Cycle World magazine archive Register Now

Dan Hunt

-

Interview

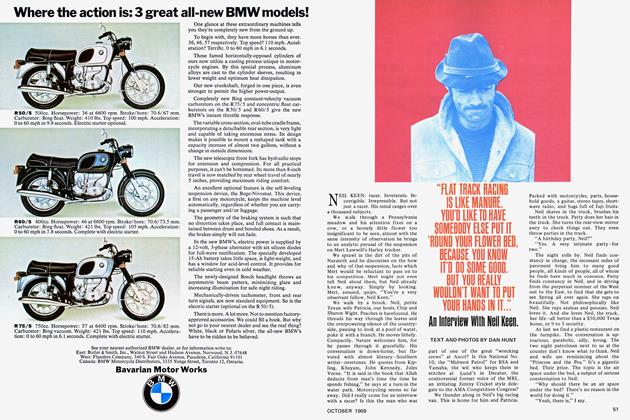

Interview"Flat Track Racing Is Like Manure. You'd Like To Have Somebody Else Put It 'round Your Flower Bed, Because You Know It'd Do Some Good. But You Really Wouldn't Want To Put Your Hands In It...”

OCTOBER 1969 By Dan Hunt -

Features

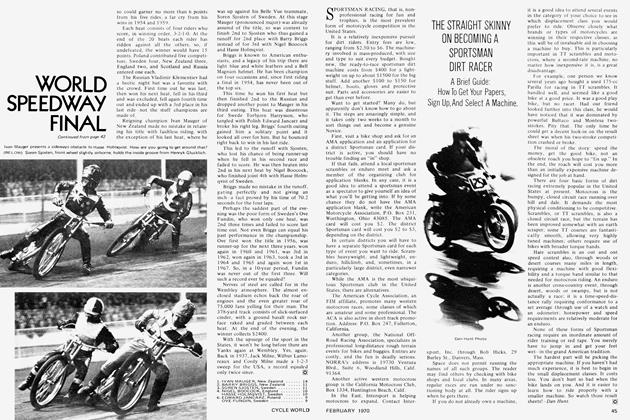

FeaturesThe Straight Skinny On Becoming A Sportsman Dirt Racer

FEBRUARY 1970 By Dan Hunt -

Special Feature

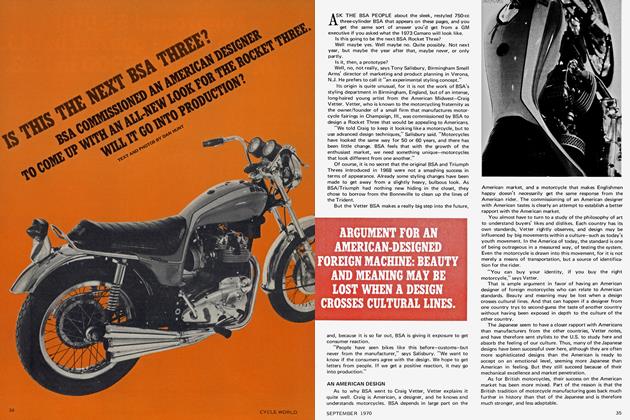

Special FeatureIs This the Next Bsa Three?

SEPTEMBER 1970 By Dan Hunt